Overcoming barriers to adoption of structural autocomposites

Although much attention has been focused on material costs and development of high-rate, automated manufacturing processes for structural autocomposites, production of viable products depends on the ability to design and simulate the structures for these exciting new FRP applications.

Effective use of fiber-reinforced polymer (FRP) composites in structural automotive applications offers enormous potential for cost savings, mass reduction and improvement in part performance. Although much attention has been focused on material costs and development of high-rate, automated manufacturing processes, production of a viable product depends on the ability to design and simulate the structures for these exciting new FRP applications.

Enabling cost-effective development

Design and simulation programs rely on representative material characteristic data to generate capable solutions. This comprehensive data set is fed into the engineers’ design software via the “material card.” To achieve an acceptable level of modeling predictability, the amount and fidelity of the material card’s data must be in line with the level of complexity of each design exercise.

Without valid material card data, a given material/process combination cannot be modeled and, therefore, parts/systems cannot be designed that incorporate those materials and processes.

Many test standards exist to characterize a given material’s performance in tensile, compressive, shear and bending modes (e.g., ASTM/DIN/ISO/EN protocols). Selecting, conducting and interpreting results from these standard test methods to generate consistent and usable data for FRP applications has been a challenge for the automotive industry. A big reason is that automotive materials suppliers are often focused only on Tech Data sheets and are insensitive to the importance of material data cards. Tier suppliers who do initiate their development tend not to share test results. The result is a lack of sufficiently broadly applicable standardized material card data for automotive applications, which presents barriers to adoption of FRP composites at the OEM level.

This issue prompted Forward Engineering, together with industry partners Hexion (Columbus, OH, US) and Zoltek (St. Louis, MO, US), to initiate a program to organize testing procedures and develop a set of best practices and methodology for translating test results into material card formats that are compatible with commercially available simulation solver programs.

Since the launch of this program in 2017, participants have been able to accelerate their FRP part development, reducing program costs as well as providing visibility to material testing budget and timing requirements for the evaluation of new materials and processes.

Modular testing program

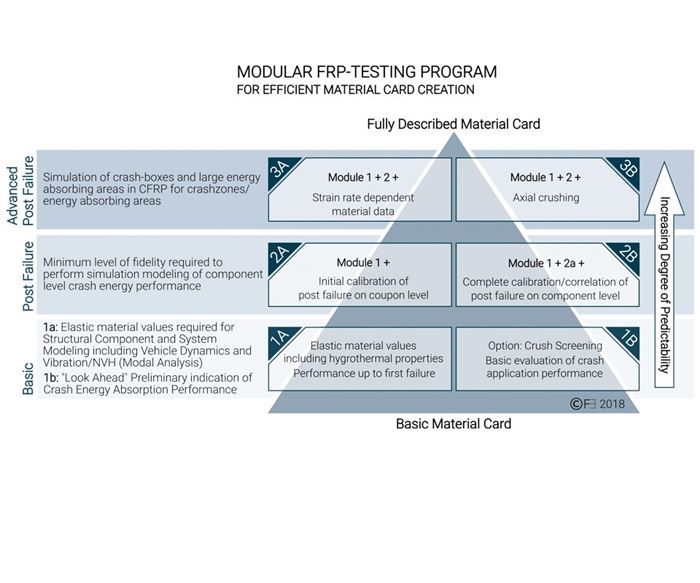

The team’s objective was to develop a flexible platform that was cost-effective and scalable. Thus, the new testing program was structured to be modular (Fig. 1). The modules required to support each application’s design program are dictated by where a given material will be employed on the vehicle and by what job(s) the material needs to perform (e.g., it might need to provide the part’s dynamic stiffness or absorb crash energy during a front-end impact). In some cases, a proxy material (that is, a material that, depending on the application, could deliver a reasonable approximation of the expected properties desired in the target material) is available for development of preliminary design concepts, allowing specific material testing to be conducted in parallel and reducing the overall product development schedule.

The modules are organized in three levels, each building on the others. As a product development program advances and higher resolution in the design performance evaluation is required, subsequent modules can be added to increase the fidelity of the results, with a corresponding increase in modeling predictability.

Three levels of testing

At the base of the program, the Module 1a package provides basic material card information required for modeling simulation up to first failure of the material. For the most basic applications, where stiffness and dynamic loading before failure are the design constraints, and the component or system is not factored into the overall vehicle crash performance, the data from Module 1a is sufficient. In addition to stiffness and strength-related design challenges, data from Module 1a Material Card testing is used for noise, vibration, harshness (NVH) simulation (modal analysis) and vehicle dynamics simulation.

Module 1b, Crush Screening, is a series of tests designed to provide a quick assessment of crash energy performance. For those materials where post-failure crash performance is important, a relatively quick and cost-effective Crush Screening evaluation can be performed to evaluate combinations of materials (resins, fibers, additives) to assess their relative crash energy behavior.

For applications where understanding post-first failure crash performance behavior is required, it will be necessary to advance to Modules 2a and 2b. These modules focus on the material behavior after the first failure, when cracks begin to form and propagate through the material with increasing load and deformation. The level of fidelity derived from Module 2a testing will support initial structural component level crash modeling. To achieve a more accurate picture of the post-failure energy absorption behavior, Module 2b, a part-level hardware test of more complex three-dimensional components, is required.

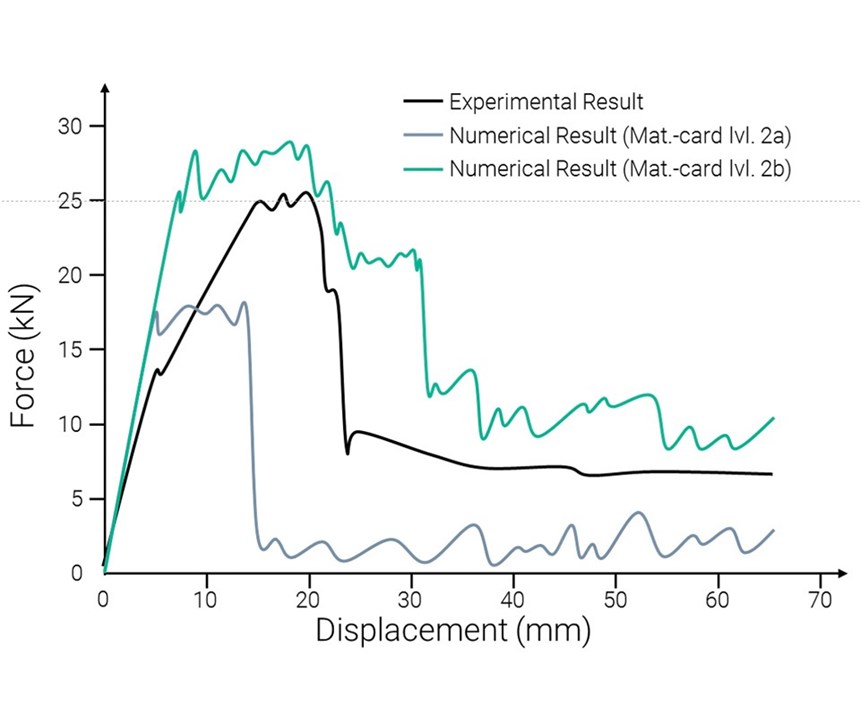

The additional fidelity provided by Module 2b results supports accurate modeling of larger, more complex subsystems (e.g., front-end modules/crush zones). The improved correlation between sample testing and modeling results can be seen in the graph in Fig. 2. With each module that is performed, a considerable increase in simulation forecast quality is observed.

Module 3a – Strain Rate Dependent Material Testing adds another level of detail to the already high fidelity of material data from Modules 1 and 2. Given that the anisotropic nature of FRP also applies to strain rate, advanced post-failure testing must employ strain rate-specific test setups, such as drop tower and Split Hopkinson Bar. The key item for Module 3a is the solver-specific result evaluation and material card enrichment. Both material model setup and hardware testing happen in close collaboration to ensure simulation prediction quality.

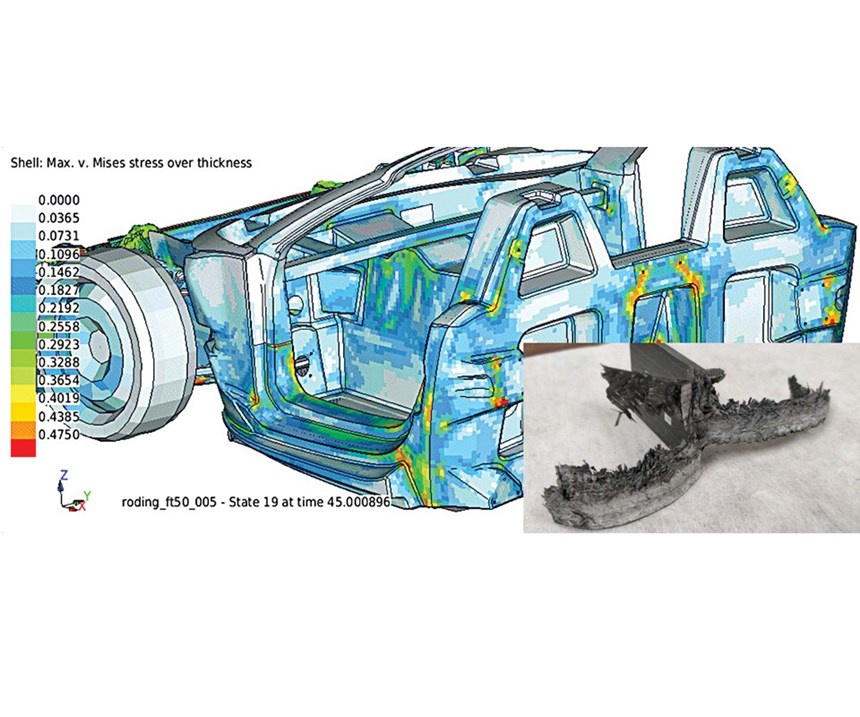

Module 3b – Axial Crush testing is focused on emulating crash structure performance often seen in high-speed vehicle crash testing (Fig. 3). Module 2a and 2b are not sufficient to model this behavior. Therefore, Module 3 comprises additional drop-tower tests to specifically recognize the energy dissipation capabilities of the material through crushing. Although the crush screening (Module 1b) describes the general suitability of the material, Module 3b captures the material behavior at energy levels common to full vehicle crash, and, depending on application, even realistic levels of strain rate.

Standardized material characterization testing program update

The development of a comprehensive, flexible, modular material card development program for automotive industry FRP applications, which otherwise would not have been possible without the support from industry leaders Zoltek and Hexion, is providing a roadmap for engineers and program managers to guide new product development, overcoming the barriers to adoption of new FRP composites by the automotive industry. The program will continue to grow with the testing of new materials (resins, fibers, cores, adhesives/joining solutions, etc.) and manufacturing processes, and this will expand the toolkit available to designers and developers of structural FRP solutions for the automotive industry.

About the Authors

Adam Halsband is the NA market manager for Forward Engineering, a global design and engineering firm based in Munich, Germany, which specializes in enabling cost-effective inclusion of fiber-reinforced composites in serial mass-produced automotive structures. From concept development through serial production validation, the company supports automotive industry stakeholders to accelerate the development and commercialization of mixed-material lightweight solutions.

Johannes Klug is a senior development engineer with Forward Engineering. He is the lead engineer within the company, and manages the development and implementation of its Modular Material Card Program. In his capacity as one of Forward Engineering’s subject matter experts, he interfaces between the design team and partner companies to drive the continuous improvement of the program and the expansion of the Material Card Database.

Related Content

Notched testing of sandwich composites: The sandwich open-hole flexure test

A second new test method has been standardized by ASTM for determining notch sensitivity of sandwich composites.

Read MoreMeasuring ply-wise deformation during consolidation using embedded sensors

Strip-type shape sensor method claims real-time measurement of ply-wise deformation.

Read MorePhotothermal tomography for locating, quantifying defects in composites

Years of infrared testing development result in thermography technology that is no longer just qualitative, but can define defect size and depth, making additional UT scans obsolete.

Read MoreTesting to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More