Testing to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Figure 1a. ASTM D7248 high bearing/low bypass test configurations. Double shear configuration (left) and single shear configuration (right). Source (All Images) | Dan Adams

A new ASTM Standard Guide, ASTM D85091, was recently published in 2023, focusing on the required coupon-level mechanical testing for developing empirical strength values to be used in composite bolted joint analyses. In contrast to conventional ASTM standard test methods, this standard guide focuses on the use of existing test methods as well as test specimen design for obtaining the required laminate strength properties. In this column I’ll provide a brief overview of the test methods to be used for this purpose.

For starters, the objective when designing a multi-fastener composite bolted joint is for each bolt to transfer the proper portion of applied load from one composite part to another. That is, a proper portion of the applied load is transferred by bearing forces exerted by the bolt onto the side of the bolt hole in the composite part. The remaining portion of the applied load bypasses the bolt through the composite part and is transferred through the composite laminate to the next bolt in line. By using the proper number and arrangement of bolts, the desired design load may be transferred across the joint without causing failure of the bolts or the composite parts. For the bolts, the primary failure mode is a shank shear failure. For the composite parts, the primary failure modes are bearing (laminate crushing) failures at the surface of the bolt holes or net tension or compression bypass failures of the laminate across the holes. Therefore, when designing composite bolted joints, a set of mechanical tests are required to address these possible failure modes and obtain the corresponding strength properties.

The ASTM D8509 standard guide focuses on three types of mechanical tests that provide the required composite laminate strength properties for use in designing multi-fastener bolted joints. The first is open-hole and filled-hole notch sensitivity testing. These tests are sometimes referred to as bypass tests since no load transfer occurs between the composite laminate and a fastener. These open-hole tests may be performed under tensile loading (ASTM D57662) or compressive loading (ASTM D64843). Both test methods specify a baseline 36-millimeter-wide specimen with a 6-millimeter-diameter through-hole, producing a width-to-hole diameter ratio of 6:1; alternate widths and diameters may be tested depending on design configurations. In addition, filled-hole testing, described in standard practice ASTM D67424, may also be used to determine the notched strength associated with a fastener-filled hole. However, since open-hole strengths typically are lower than the corresponding filled-hole strengths, the open-hole strengths are typically used for composite bolted joint analysis.

The second type of mechanical tests performed for composite bolted joint analyses are laminate bearing tests, as described in ASTM D59615. In contrast to open-hole tests, 100% of the force applied to the specimen is transferred across the two-piece bolted composite specimen through bolt bearing. In composite bolted joints, bearing failures typically consist of localized crushing of the composite laminate in contact with the fastener. Composite bearing testing may be performed following whichever of the four test procedures provided in the ASTM D5961 standard best represents the bolted joint configuration of interest. Test procedures A and D are single-fastener configurations loaded in a symmetrical double-shear configuration under tension and compression loading, respectively. Procedures B and C are single- and double-fastener configurations loaded under single-shear loading. A range of fastener types and bolt diameters may be tested depending on design configurations.

The third type of tests performed for composite bolted joint analyses are the lesser-known bearing/bypass interaction tests, which use simple, two-fastener composite specimens subjected to uniaxial loading. A net section bypass failure mode is obtained at a bolt location where there is both an applied bearing force and a bypass force. Two such composite bearing/bypass test methods have been standardized by ASTM. The first test method, described in ASTM 72486, is commonly referred to as the high bearing/low bypass test. As shown in Fig. 1a, these tests may be performed under either tensile or compressive loading using either a double-shear loading configuration using a one-piece specimen (Procedure A) or a single-shear loading configuration using a two-piece specimen (Procedure B). Note that while the Procedure B single-shear configuration is the most representative of typical bolted joint configurations, the Procedure A double-shear configuration is used for applications which involve double shear joints. The ratio of the bearing force to bypass force at a given bolt hole is determined by the relative stiffness of the specimen and fixture plates (double shear) or the two specimen laminates (single shear). In most cases there is a 50:50 distribution of force between the two bolts.

Figure 1b. ASTM D8387 high bypass/low bearing test configurations. Tensile test specimen with doubler plates (left) and compressive test specimen with doubler plates and support fixture (right).

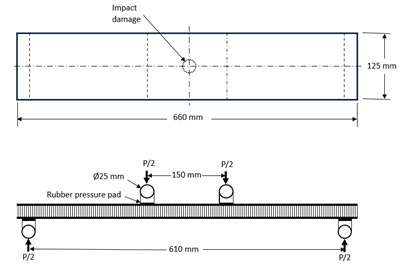

The second bearing/bypass interaction test method, described in ASTM D83877, is referred to as the high bypass/low bearing interaction test. As shown in Fig. 1b, this test is performed using a one-piece composite specimen with two bolt holes machined 50 millimeters apart along the specimen centerline at the midpoint of the specimen. A 90-millimeter-long steel doubler plate is bolted onto each side of the composite specimen using the two machined holes at the center of the specimen. For tensile loading, the bolted-on doubler plates act as “hardpoints” and thus induce low levels of bearing forces into the test specimen, while most of the applied force is transferred directly through the laminate as bypass. Typically, specimens are designed to have between 5-20% of the load transferred in bearing. For compression loading, a support fixture is required to stabilize the specimen during testing. As a result, the size of the doubler plates are reduced to fit into the opening in the support fixture. These interaction specimens require detailed calibration procedures that are provided in the test method.

Having summarized the three types of mechanical tests that provide the required strength properties for use in designing multi-fastener composite bolted joints, I’ll summarize how they may be used collectively when designing bolted joints in composite structures. Fig. 2 shows schematically a composite laminate bearing/bypass interaction diagram along with representative data obtained from these mechanical tests. In this empirical joint interaction plot, the maximum bearing stress produced in a specimen is plotted on the horizontal axis with the “gross” bypass strain plotted on the vertical axis. Bearing strength data are plotted on the horizontal axis, while open-hole strength data are plotted on the vertical axis. The bearing/bypass interaction strength data is used to define the strength envelope between the axis points; these sloping lines represent net section bypass failure modes.

Figure 2. Example bearing/bypass interaction diagram with illustrative regions of test data obtained from supporting test methods.

Further information on the topic of composite bolted joint analyses, as well as the required testing, is available in Volumes 1 and 3 of the CMH-17 Handbook8.

The author would like to acknowledge the contributions of Steve Ward (SWComposites) toward the development of this ASTM D8509 standard guide and for his assistance in writing this column.

References

1 ASTM D8509/D8509M-23, “Standard Guide for Test Method Selection and Test Specimen Design for Bolted Joint Related Properties,” ASTM International (W. Conshohocken, PA, US), 2023.

2 ASTM D5766/D5766M-23, “Standard Test Method for Open-Hole Tensile Strength of Polymer Matrix Composite Laminates,” ASTM International (W. Conshohocken, PA, US), 2023 (first issued in 1995).

3 ASTM D6484/D6484M-23, “Standard Test Method for Open-Hole Compressive Strength of Polymer Matrix Composite Laminates,” ASTM International (W. Conshohocken, PA, US), 2023 (first issued in 1999).

4 ASTM D6742/D6742M-23, “Standard Practice for Filled-Hole Tension and Compression Testing of Polymer Matrix Composite Laminates, ASTM International (W. Conshohocken, PA, US), 2023 (first issued in 2001).

5 ASTM D5961-23, “Standard Test Method for Bearing Response of Polymer Matrix Composite Laminates,” ASTM International (W. Conshohocken, PA, US), 2023 (first issued in 1996).

6 ASTM D7248/D7248M-23, “Standard Test Method for High Bearing - Low Bypass Interaction Response of Polymer Matrix Composite Laminates Using 2-Fastener Specimens,” ASTM International (W. Conshohocken, Pa.), 2023 (first issued in 2007).

7 ASTM D8387/D8387M-23, “Standard Test Method for High Bypass - Low Bearing Interaction Response of Polymer Matrix Composite Laminates,” ASTM International (W. Conshohocken, Pa.), 2023 (first issued in 2021).

8 Composite Materials Handbook – 17 (CMH-17) Volume 1: Polymer Matrix Composites - Guidelines for Characterization of Structural Materials, Rev H, 2021, Volume 3: Polymer Matrix Composites - Materials Usage, Design, and Analysis, SAE International, Rev. G, 2012.

Related Content

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreRead Next

Development of ASTM standards for composites: An insider’s perspective

According to Dan Adams’ inside perspective, two elements determine whether a proposed test method for composite materials becomes an ASTM standard.

Read MoreDamage tolerance testing of sandwich composites: The sandwich flexure-after-impact (FAI) test

A second new ASTM-standardized test method assesses the damage tolerance of sandwich composites under flexural loading.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More