Polyurethane’s processing speed, properties enable bigger blades

Decade-long development effort reaches key wind energy cost-reduction milestone using epoxy-besting infusion resin.

Wind turbine blades remain a key market segment for composites. According to the new report “Wind Turbine Composites Material Market: Global Trends & Forecast to 2020” by MarketsandMarkets (Magarpatta City, India and Seattle, WA, US), the market for composites in wind turbines — comprising mainly nacelles and rotor blades — totaled US$7.2 billion in 2015 and is expected to grow at a CAGR of 9.3% to reach US$12.2 billion by 2021, thanks especially to increasing demand in China, India, South Korea and Japan.

The wind industry consultancy MAKE (Chicago, IL, US and Aarhus, Denmark) estimates that roughly 650,000 wind turbine blades will be produced between 2017 and 2025, with a 12-15% increase in the average rotor diameter. “Blade lengths continue to increase,” says MAKE partner Dan Shreve, “offering an enormous market opportunity for blade OEMs and their strategic materials providers.”

A key facet of that opportunity is to find new ways to reduce blade cost. Although the cost of building and operating wind turbines has decreased significantly over the past two decades, “blades are still 25-35% of the total wind turbine cost,” says Covestro's (Leverkusen, Germany) Kim Harnow Klausen.

Klausen is the head of Covestro’s program to develop polyurethane (PU) as an optimized matrix resin for composite wind blade production. Begun in 2009, the program produced a demonstrator glass fiber/PU spar cap for a 45m long wind blade —the focus of this article — using resin infusion in 2015. “We have now made the first polyurethane wind blade in Asia, a 37.5m long blade for a 1.5-MW wind turbine in China,” says Klausen. For this blade, all of the components — spar, web, root and shell — were infused using Covestro’s PU resin. “We are also going to make a larger blade this year,” he adds.

Why polyurethane? “The resin we have developed is 10-25% stronger than epoxy,” Klausen claims. PU also offers inherently lower viscosity — below 100 cps at 25°C — for faster infusion, as well as a faster cure and less exotherm during cure vs. epoxy, vinyl ester (VE) and polyester systems. Further, as blade length increases, so does the need for improved properties and fatigue performance, as well as fabrication speed.

MAKE sees the potential of polyurethane in blade production. “We have identified this as an early-stage material advancement that can help reduce blade production cycle times while also cutting nonconformance costs due to irregular wet out of larger blades,” says Shreve.

“It’s all about lowering the levelized cost of energy [LCOE],” Klausen contends. “If we can make blades 10-15% cheaper to produce while decreasing their weight and enabling them to perform well at increasingly longer lengths, then we can drop LCOE even further.”

Early promise, long development

In 2009, Covestro, then Bayer MaterialScience (Leverkusen, Germany), received a grant from the US Department of Energy (DoE) to research PU composites for use in wind turbine blades. Researcher Marcio Loos at Case Western Reserve University (Cleveland, OH, US) investigated the processing and properties of a 0.74m-long wind blade made using infusion, glass fiber fabrics and PU resin.

In 2011, Loos reported that the PU composite bested glass fiber/epoxy, lasting eight times longer in fatigue testing and showing a fracture toughness roughly eight times higher in delamination tests. Further, fracture growth rates were shown to be a fraction of those for epoxy and vinyl ester composites.

The following list of additional ways PU bests epoxy were compiled in a 2012 presentation by Loos’ co-researcher Usama Younes at Sandia National Laboratories (Albuquerque, NM, US), based on multiple investigations of PU with glass and carbon fiber, including resin infusion molding of a thick, glass/PU root ring for a 42m long wind blade:

- 34% less time required for infusion of thick (50-ply) laminates.

- >17% greater tensile strength.

- Almost double the interlaminar fracture toughness.

- 30% lower stress crack growth rate.

- Better adhesion to glass fiber.

That same year, Bayer announced it would establish a global wind energy competence and development center in Otterup, Denmark. The facility would go on to spearhead and coordinate global development of Covestro’s advanced materials for wind energy applications (after the name change in 2015) under Klausen’s leadership, then managing director of Bayer MaterialScience A/S, Denmark. Although the idea to use polyurethane as an infusion resin originated in the US, Klausen notes that today, development and optimization of the PU resin chemistry are being performed cooperatively by Covestro’s Polymer Research & Development Center (PRDC, Shanghai, China) and the wind energy center in Otterup, with oversight from Jan Drescher, head of the European infusion resin project in Leverkusen.

“The formulation we are working with now,” he points out, “is quite different than what was presented at Sandia in 2012.”

Are the property and processing improvements similar? The advantages in terms of reduced infusion time and improved mechanical properties compared to epoxy and vinyl ester infusion formulations have been maintained, Klausen confirms, but he prefers not to reveal specific property values until this infusion resin’s certification by DNV GL (Oslo, Norway) is complete. That process, he estimates, will conclude sometime this year. Notably, a previously formulated Covestro PU resin was the world’s first PU resin to receive DNV GL certification.

In 2015, Klausen partnered with the Center for Lightweight Production Technology (ZLP) in Stade, Germany, a division of the German Aerospace Center (DLR, Cologne) that collaborates with the DLR Institute of Composite Structures and Adaptive Systems in Braunschweig and the Institute of Structures and Design in Stuttgart. Established to enhance cooperation between science and industry, it works to optimize composites production technologies. The ZLP contributed significant blade design and manufacturing experience and a 45m wind blade mold, previously used by turbine maker Nordex (Hamburg, Germany).

Finalizing fibers and process

The project to demonstrate Covestro’s latest developments in a polyurethane resin for wind blades was now set — infusion of a 45m long spar cap, the primary structural element of a wind blade. At this point, two final project partners were invited to participate: reinforcements and core materials supplier SAERTEX GmbH & Co. KG (Saerbeck, Germany) and process engineering specialist and equipment supplier Hübers Verfahrenstechnik Maschinenbau (Bocholt, Germany).

“We received a request from DLR to provide unidirectional [UD] glass fiber reinforcements,” recalls SAERTEX account manager Alexander Winter. “These UDs are a material we commonly supply into wind blade spars,” he notes. They comprise two layers: a stabilization layer of 90° fibers, weighing only a few grams per square meter, and the unidirectional 0° layer, which provides strength along the length of the spar. “The fabric used in the spar cap demo project was one we had specifically developed for a 45m spar,” says Winter. It featured a 1,182g/m2 a real weight and 670-mm width. SAERTEX has made this type of noncrimp fabric (NCF) with glass fiber as heavy as 4,000 g/m2 and as light as 230 g/m2. It also can slit this type of fabric into widths that range from a few centimeters up to 3m. “For many fabrics, the normal production width is 50 or 100 inches [1.3 or 2.5m],” says Winter, “but UDs are typically 200-600 mm in width.” To help speed layup, especially for blade skins, SAERTEX also kits fabrics for a variety of manufacturers — e.g., 100 cut and labeled NCF pieces per box.

“We selected glass fibers with a sizing that is compatible with the Covestro PU resin,” Winter recalls. Covestro also completed smaller-scale infusion tests in advance (see Step 1).

Like other infusion resins used in wind blade construction, PU requires the metering, mixing and dispensing (MMD) of two components, typically achieved using specialized equipment (see Meter/mix/dispense machines: Doubling down on control). Klausen explains selection of the final project partner. “Hübers was brought in because we wanted to use very advanced process control,” he says. “One reason for this was to minimize the processing variability, so that we could see what the resin was achieving. But we also pursue top-class solutions for industry as a general approach.”

Klausen did not seek traditional polyurethane machine specialists because they lacked familiarity with vacuum degassing in the resin tank. He explains, “Hübers’ background is incast polymers for electrical transformer applications, where any bubbles can generate a spark. So, they have developed very tight process control along with inline vacuum degassing of the resin, which provides very reliable, consistent and high-quality infusion results.”

Demonstration and future development

All project partners were on site for infusion of the 45m spar cap. “The team worked well together. DLR was very experienced and there also were some staff from a rotor blade manufacturer who provided assistance,” says Winter.

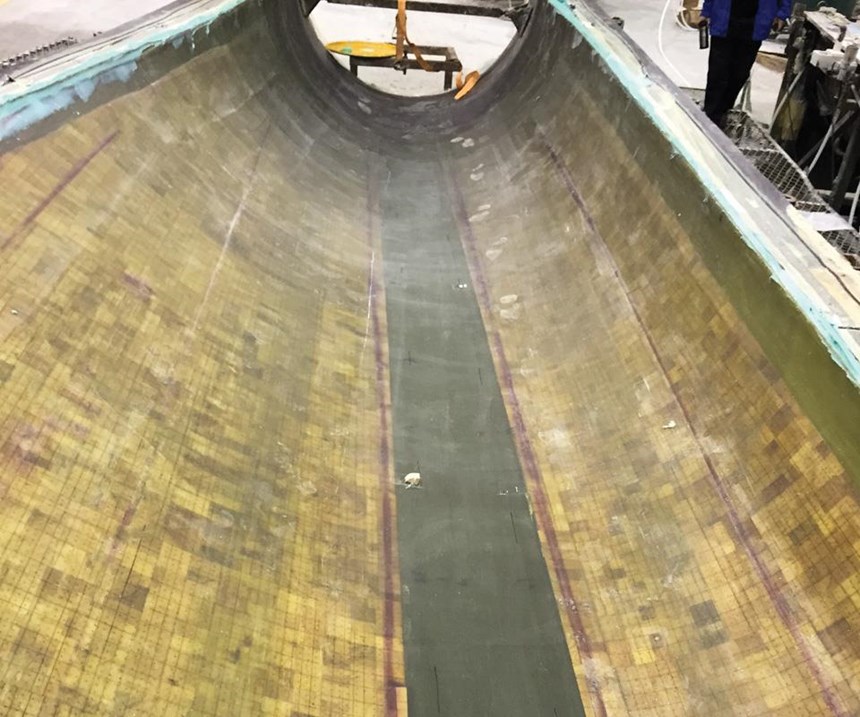

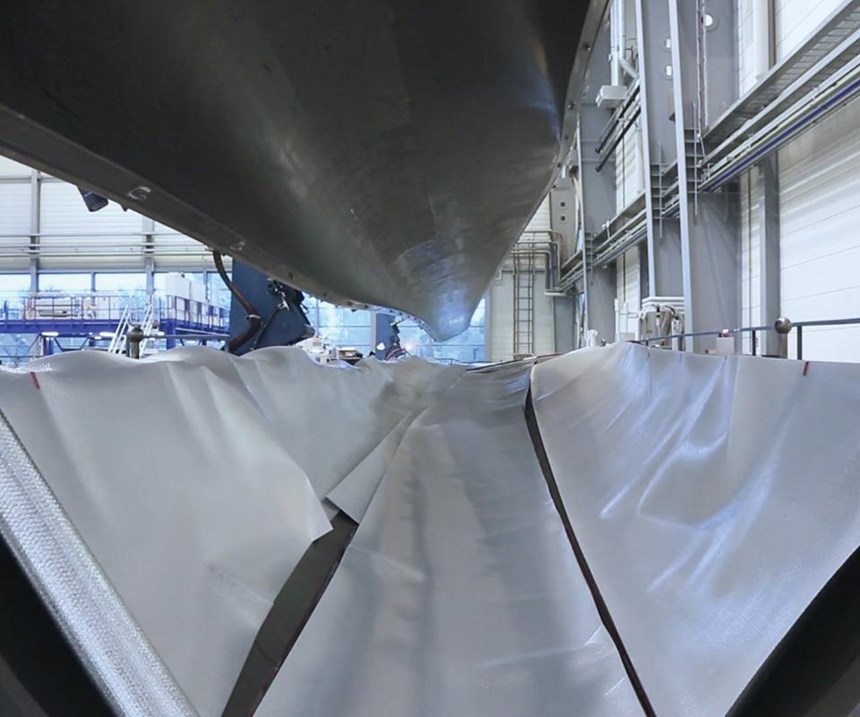

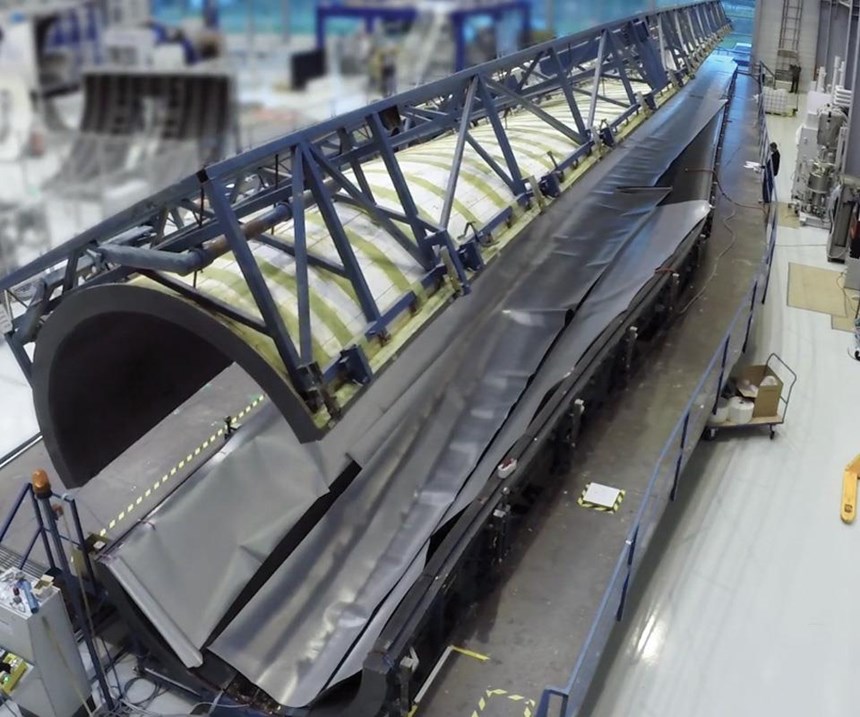

First, the mold was prepared by applying a release film using standard materials and process (Step 2). Next, 52 plies of the dry glass fiber uni materials were placed into the mold (Step 3). Then the vacuum bag, resin supply/feed lines and vacuum lines were installed (Step 4) and the infusion was started (Step 5). The setup used just one central feed line; two additional lines were available as backups only. Infusion of the spar cap was completed in 46 minutes.

Klausen explains that the Tg of the PU resin is slightly higher than epoxy, but the cure temperature is very similar, at 80°C. This was achieved using heated molds, a standard practice in blademaking. Once infusion was complete, insulation blankets were placed over the infusion setup, per standard blade manufacturing practice, to reduce heat loss for a more efficient heating and cure cycle (Step 6) A video of the spar cap infusion shows the wind blade mold closing (also shown in Fig. 7) but Klausen says this was not necessary for curing just the spar cap, but was done more as a demonstration of the process necessary to mold a complete blade. Four hours at 80°C is enough to cure the polyurethane resin, but Klausen believes his team can reduce the cure duration significantly.

Capturing savings in cost and time

“We were able to cut both infusion time and cure time compared to epoxy,” says Klausen of the spar infusion, who estimates that overall blade production time could be cut by >10%. “The price of this polyurethane is competitive with epoxy,” he explains, “but the process savings would then give an overall advantage.” Is this possible for all resin-infused blades? “You can never state that it is possible for all blade types or designs,” replies Klausen, “because there are so many different solutions and production methods, which create individual challenges. However, the lower viscosity and curing time of our resin can save time.” He estimates that most parts can be produced 10-20% faster with this PU system vs. epoxy, adding that “It will probably be necessary to adapt the injection equipment and flowlines to make use of the higher infusion speed.”

This single PU resin can be used for all blade components, Klausen points out, including root, spar cap, spar web and shell, as has been demonstrated in the 37.5m long blade in China. “It is also possible to use it only for one of these components while maintaining the others in vinyl ester or epoxy,” he notes. “This resin is compatible with vinyl ester and epoxy, so you can achieve good adhesion.” Because the wind blade industry is conservative, Klausen acknowledges that blade manufacturers may want to switch over one structure at a time, to build experience and confidence.

He notes that blade designers can simply drop in the PU system to replace the current infusion resin, “but if you really want the full savings possible, then you look at your design and how to exploit the higher resin properties.” Because of the resin’s higher strength — including higher compression vs. epoxy — designers can either cut weight out of the blade or use these advantages to achieve, longer, slimmer blades for bigger turbines and/or more power. “We are working with a well-known wind blade design firm now, WINDnovation [Berlin, Germany], to calculate the design advantages of using this polyurethane resin.”

Klausen believes that even designers who prefer to take the drop-in approach one structure at a time on their current production blades will nevertheless redesign their next-generation blades to fully capture the PU property benefits. “This is why we are fully documenting the design possibilities with WINDnovation,” he adds.

“We will also move forward with further demonstrating the resin in larger blades,” says Klausen. The current plan is to build further full-blade prototypes and test them extensively during the next year. “Our goal is to provide test results that will be accepted internationally,” he notes, “so we will choose a well-recognized test facility for this demonstration.”

There is also the possibility to do more demonstrations with DLR. For its part, SAERTEX would like to participate in larger blade demonstrations using its new core material, SAERfoam. “This would replace balsa wood core for a 25% weight reduction, depending on the blade design,” says Winter, who sees applications for the new core beyond wind, such as in marine and construction/infrastructure.

Klausen also sees opportunities beyond wind for Covestro’s new PU infusion system, but for now, the focus is on finishing the development for rotor blades. “We will spend 2017 documenting all of the resin and composite mechanical properties as well as the aging properties,” he observes. “We will also do a lot of health, safety and environmental testing and documentation.” Klausen explains that Covestro has many internal standards that exceed, sometimes significantly, others in the industry, such as DNV GL. “We must fulfill all of these first — for example, performing grinding on cured composites with this resin, collecting the dust and analyzing it,” he notes. “We will then be able to present a complete package to the end-users.” In the meantime, his team is finalizing further demonstrations, and aiming for final commercialization in 2018.

Related Content

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)