Recycled carbon fiber on the rails

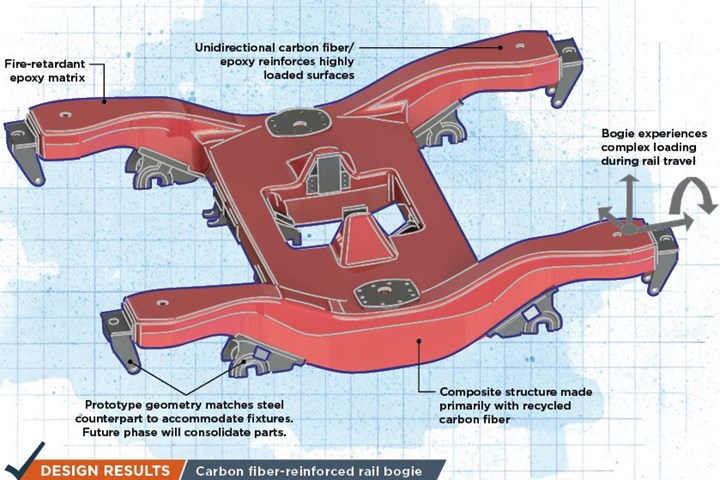

Aiming to increase the cost-weight viability of carbon fiber-reinforced composite structural components in railway vehicles, a prototype rail bogie prominently features recycled carbon fiber.

Source | Sue Kraus

A large market for composite structural components may be opening up within a decade, and recycled carbon fiber may be the key. At least, this seems to be the promise proffered by the recent completion of a prototype rail bogie by a United Kingdom industrial-academic consortium. Bogies are the four- or six-wheel trucks that support rail vehicles and provide traction and braking. Usually each rail vehicle has two bogies, one near either end. Funded by the U.K.’s RSSB (Rail Safety Standards Board), the composite bogie prototype represents the culmination of a three-year effort, which has included conceptual and design work, materials testing and qualification, manufacturing engineering and fabrication of the bogie and assembly with standard fittings. The bogie, which is made primarily with recycled carbon fiber composites but is supplemented with virgin carbon fiber composites in places requiring additional strength or stiffness, was the subject of two presentations at the “Unlocking Innovation Scheme — Composites in Rail” event in June 2019, and was unveiled during a subsequent “Unlocking Innovation” event in Dec. 2019.

The bogie was officially unveiled at an event at the University of Huddersfield on Dec. 10, 2019.

Initiated by ELG Carbon Fibre Ltd. (Coseley, Dudley, U.K.), the consortium now consists of ELG, which supplies the recycled carbon fiber and performed much of the materials testing; Magma Structures (Portsmouth, U.K.), designer and fabricator of the rail bogie; the University of Birmingham (Birmingham, U.K.) Sensors and Composites Group, which worked with Magma to develop an embedded health monitoring system for the bogie; and the University of Huddersfield (Huddersfield, U.K.), on whose dynamic test rig the prototype is to undergo initial full-scale testing. Alstom U.K. (London) helped to assemble the consortium and has provided additional support through consulting and existing bogie design information.

In the past, this market’s pursuit of composite structural components has stalled due at least in part to the high cost of carbon fiber. The lower cost of recycled carbon fiber has tipped the scales enough to prompt the consortium’s funding and current work, and perhaps enough for the eventual opening of this market to production bogies. With the potential for some 36,000 bogie frames to be built in the next 10 years for passenger rail vehicles in the U.K. alone, pursuing this market is certainly a worthwhile endeavor.

A promising application

The RSSB’s interest in the project stems from the U.K. government’s expenditure of millions of pounds each year in track repairs and maintenance. Railway service providers offset this cost to a degree through track access charges, which are computed based on railcar weight and stiffness (both of which affect track wear and tear), but maintenance costs still add up. This means that both the track provider and the service providers are financially motivated to reduce railcar weight while optimizing structural strength and flexibility. Rail operators employing composite bogies will also be able to optimize operating costs by balancing the energy savings gained from the lighter weight bogie with the opportunity to increase payload weight and thus increase delivery volume per railcar.

One kilogram of carbon fiber-reinforced composite typically replaces 3 kilograms of steel in a structural application, so considering that the typical steel rail bogie with fittings weighs about 1,500 kilograms, lightweighting can be expected to reduce railcar travel costs substantially. In fact, using the annual miles traveled by trains in the U.K. and inflation-adjusted RSSB values for the cost of electricity and maintenance, the consortium estimates potential annual savings ranging from £10.16 per kilogram of weight saved in inner suburban rail transit, to £105.80 per kilogram of weight saved for high-speed rail transit.

The consortium selected the Alstom Class 180 bogie frame as the target application, reports Frazer Barnes, managing director of ELG Carbon Fibre, because it is representative of many bogie frame designs, has well understood performance and has a ready supply of the fittings that attach to the frame. These advantages, however, also placed restrictions on the prototype's design. Specifically, the geometry of fitting attachment points on the composite bogie had to conform to those on its steel counterpart in order to properly incorporate existing fittings and equipment. The prototype’s design therefore is not fully optimized to take advantage of composite properties, but this leaves a good opportunity for greater benefits in future designs.

A lighter bogie directly contributes to the anticipated cost-in-use savings generated by a composite version, and so will the greater flexibility afforded by composite materials. As a train travels around curves, it places dynamic forces on the rail, explains Damon Roberts, Magma Structures engineering director, and the bogie needs flexibility in the lateral plane as it negotiates these turns. Optimizing the bogie’s rotational (yaw) stiffness could contribute to a reduction in lateral loads on the track rails of up to 40%. “Many composite designs aim to optimize stiffness more than strength,” Roberts notes. “In the bogie design, we have introduced more flexibility with plenty of strength.”

Additionally, the lighter weight bogie should experience reduced suspension maintenance costs. In fact, Roberts reports, at the conceptual stage the design team considered integrating suspension and steering functionality into the bogie, which would result in a more flexible primary suspension that would further reduce lateral forces on the rail tracks. This plan proved too involved to incorporate in the prototype, but is under consideration for future efforts.

Building a case for recycled carbon fiber

With recycled carbon fiber reducing the cost premium of a composite bogie, one of the early tasks for the consortium was to characterize recycled carbon fiber-reinforced composites to the satisfaction of rail stakeholders. This characterization was especially important given the rail industry’s perception that composites are a basic material for non-structural, interior applications. “This is a very, very conservative industry,” Barnes says, “and rightly so. They are extremely safety conscious, given the impact that an accident or structural failure might have.”

In an effort to convince this industry that recycled carbon fiber-reinforced composites are suitable for primary structures, the consortium reported numerous physical and mechanical property comparisons. ELG Carbon Fibre has demonstrated that interfacial shear strength, critical to the performance and durability of a composite material, is comparable between recycled and virgin carbon fiber reinforcement in epoxy. The recycled carbon fiber/epoxy selected for the rail bogie demonstrates comparable tensile strength to bogie frame steel. (The consortium chose epoxy resin because of its adaptability, durability and well-understood mechanical properties.)

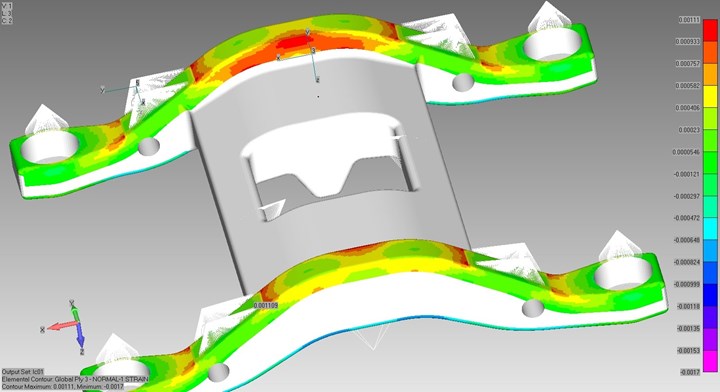

Specifically, the consortium needed to demonstrate that the recycled carbon fiber would meet the fatigue and fire performance requirements of rail applications. The consortium selected ELG Carbon Fibre’s Carbiso M, a nonwoven mat made with standard modulus fiber (strength of 4 to 5 GPa) in an epoxy matrix. They demonstrated that the fatigue performance of the recycled carbon fiber/epoxy is similar to that of conventional woven carbon fiber laminates — and better than that of structural steel, Barnes emphasizes. Finite element analysis (FEA) performed by Applied FEA Ltd. (Southampton, U.K.) verified fatigue service loads as well as exceptional static loads.

For acceptable fire performance, the consortium selected a fire-retardant epoxy that offers properties similar to a conventional epoxy. Determining how to test the composite for fire performance presented another hurdle for the team to overcome. “The standards are there, but how do you test for those standards?” Barnes asks. “For example, does the standard apply to the surface of composite laminate or the full depth of material? We decided to have all the material pass the fire test standard, taking a conservative approach.” The composite material was required to achieve the HL2 rating under the European Union’s EN 45545-2 railway standard for fire safety, which includes specifications for spread of flame, heat release, smoke density and smoke toxicity. It achieved the more stringent HL3 rating.

Design particulars

The Carbiso M recycled carbon fiber nonwoven is the key reinforcement used in the “skin” of the rail bogie, prepregged with the selected epoxy by Gurit (Newport, Isle of Wight, U.K.). The prototype also employs composite lamina made with virgin unidirectional carbon fiber oriented at 0 and ±45 degrees in places where additional strength and stiffness are required, primarily along the upper and lower faces of the bogie’s outer legs. Virgin carbon fiber composite makes up 50% of the total composite material in the bogie. The design analysis that led to this combination took into account the complex interaction on each leg of strength, stiffness and safety factor calculations in the three principal planes (x, y, z) and torsionally.

With Magma Structures’ experience in building high-pressure offshore composite pipes (see “Thermoplastic composite pipe on the rise in the deep sea”) with robotic material deposition, the company was able to employ some robotic deposition to lay up the prepreg plies, followed by autoclave cure. Roberts reports that the company intends to increase the level of robotic deposition when the bogie development process reaches a large batch production stage. “When it first came up to do this, one of the main aims was to do it with a cost-effective technique,” he recalls.

The consortium also benefited from Magma Structures’ experience with embedded fiber optic strain monitoring and managing fixtures on composite structures like the large composite masts for which they are known (see “Magma Structures delivers massive superyacht masts”). Including these masts, Magma has built some of the largest and most highly loaded carbon fiber composite structures in the world. “We rely on monitoring technology very heavily on our composite rigs,” Roberts says. “We see the rigging’s loads every day; they come to me on my desk.” The company worked closely with the University of Birmingham to incorporate the bogie’s fiber-optic strain monitoring system.

Compared to the original steel Alstom 180 bogie frame and fittings, the prototype is 36% lighter. The composite frame itself yields a 64% weight savings, but the prototype suffers a weight penalty from paint and the tapping plates needed to attach the steel fittings — a penalty that may be largely eliminated in a fully optimized design. Considering the frame alone, the 590 kilograms of weight saved is estimated to produce an annual savings in operating costs of between £8,000 and £62,000, depending on the train’s service type and mileage. Additionally, each bogie frame could reduce CO2 emissions through its lifetime by as much as 68 metric tonnes.

In transit

The full-scale tests scheduled for this month will take place at the University of Huddersfield on the Huddersfield Adhesion and Rolling Contact Laboratory Dynamics (HAROLD) test rig. During this testing, the fiber-optic monitoring system will collect data to be evaluated against design and FEA models, and at the same time the testing will verify that the monitoring system itself can withstand proof and fatigue loading.

Development and track testing of a more optimized bogie prototype is next for the consortium. Magma Structures plans to build two such bogies for this in-field testing. Barnes points out that the integration of fittings into the composite structure may save another 100 kilograms per bogie. “It would make the structure more elegant but not significantly more complex to manufacture,” he says.

Roberts sees future developments taking a path similar to that seen in other composites markets: start with a metal design and substitute with composites, then take greater advantage of composite materials’ heterogeneous, anisotropic properties.

“Steel structures have often been designed on an empirical basis with a homogenous isotropic material,” Roberts says. As the consortium moves forward, they’d like to take a different approach. “We want to move back one stage and ask what we are trying to achieve, and whether we can quantify it. You need to know what you want. It sounds obvious, but if it’s difficult to define what you want, it’s difficult to achieve what you don’t know.”

Related Content

Longtime partner New Flyer selects Hexagon Purus to outfit hydrogen transit bus

Hexagon Purus will continue to supply Type IV hydrogen tanks for the Xcelsior Charge H2 fuel cell electric bus, the tanks of which will be produced out of Hexagon’s new Maryland facility.

Read MoreSABIC debuts EN45545 rail-compliant, fiber-reinforced compound

LNP Thermocomp AM DC0041XA51 offers the rail industry a solution that can be used for on-demand printing of large, complex exterior and interior parts in relatively small build numbers.

Read MoreHexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreNew Flyer selects Hexagon Purus H2 tanks for fifth consecutive year

Type 4 tanks will continue to be supplied for the mass mobility provider’s Xcelsior Charge FC fuel cell electric transit buses.

Read MoreRead Next

Building confidence in recycled carbon fiber

Recycled carbon fiber is proving, increasingly, to be a cost-effective, environmentally sustainable composite solution for automotive and other high-volume applications.

Read MoreWMG prototypes CFRP frame for Very Light Rail (VLR) demonstration vehicle

Braided thermoplastic composite frame enables lightweight, recyclability and high-volume manufacturing.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read More

.jpg;maxWidth=300;quality=90)