Reformable composite equestrian saddle

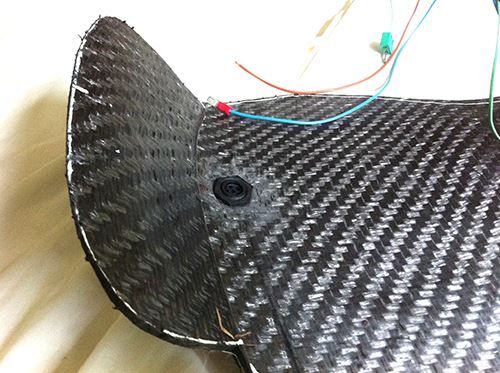

This carbon fiber/polyethylene terephthalate (PET) saddle tree features an intralaminate heating element that enables horse owners to reconfigure saddle shapes as horses grow, greatly reducing long-term saddle-fitting costs.

The effectiveness of LaminaHeat LLC (Greenville, SC, US and Dorset, UK) PowerFilm and PowerFabric materials in heated composite tooling and structures was recently demonstrated in a very big way, via an 18m long carbon fiber (CF) composite tool used by Norco GRP Ltd. (Poole, Dorset, UK) to cure the tips of Blade Dynamics’ (Southampton, UK) 75m-long composite blades for 6-MW offshore wind turbines (read more by clicking on “Heated composites” under "Editor's Picks" at top right).

PowerFilm, a thin (100 microns thick) layer of randomly oriented carbon fiber insulated with a polymer and incorporating copper contacts, converts electricity into heat so efficiently that it can generate up to 10 KW/m2 — roughly the same heat as three gas fires — from only 1m2 of material. In fact, PowerFilm converts with 99% efficiency vs. 80% for gas flame, according to technology developer Peter Sajic. Before demonstrating its prowess in processing turbine blades, PowerFilm was first trialed in carbon fiber/polyethylene terephthalate (PET) composite structures for equestrian saddles, providing a solution that could have far-reaching application, from sporting goods to medical devices.

Sajic had friends involved in horse training and knew of the issues with fitting saddles. “One of the biggest problems in the industry is that the shape of the horse changes as it grows and matures, just like in people,” he explains. The saddle must be sent back to the saddle maker, who adjusts its shape to better fit the horse, to prevent chafing, discomfort and potential injury. This must be done at least twice annually at a cost of roughly £350 (US$550) each time. Sajic says the saddle maker must first send someone out to measure the horse with a special gauge. The saddle is then disassembled and a hydraulic ram is used to open the width of the saddle tree, or frame structure, principally in the neck area. “Though the gauge measurement is used to guide the widening,” says Sajic, “it is still, typically, a trial-and-error process.”

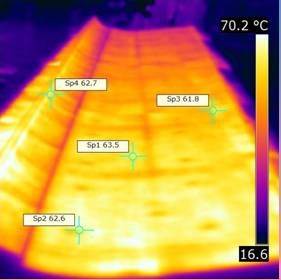

Sajic proposed a PowerFilm-enabled composite alternative that enables a saddle to “grow with the horse.” “With our system,” Sajic counters, “you have the saddle on the horse and simply connect a power source via a plug at the rear of the CF/PET saddle tree.” The latter heats up to 120°C-140°C (the leather acts as an insulator, so that the horse feels about 25°C). A saddlejack is used on top of the saddle to widen the neck area of the now-pliable laminate until it matches the horse’s shape comfortably.

“We designed the PowerFilm to hit 120°C in 2 minutes,” explains Sajic. ”It uses a 24-volt DC power source, so it’s very safe.” (The power source is the equivalent of rechargeable battery packs used for power hand tools.) The power cord is actually disconnected after 2 minutes, he says, but thanks to the insulation of the saddle’s foam and leather, the saddle tree temperature remains high enough for 20 minutes of forming, which is usually more than sufficient.

The CF/PET saddle tree is made using 12K CF tow (larger tow could be used) commingled with linear PET (LPET) fiber. The latter enables lower processing temperatures vs. normal PET. The commingled tows are woven into fabric by Carr Reinforcements Ltd.(Worsthorne, UK). The dry fabric — much like a thermoplastic prepreg — is then hand layed onto a metal tool, with the PowerFilm and electric wiring to the power socket embedded within. The layup is then vacuum bagged, heated to 190-200°C and cured under vacuum for 20-30 minutes. After demolding, it’s trimmed to size and ready to form the structure for the saddle. The CF/PET laminate tapers in thickness from 7 mm at the neck to 3 mm at the end of the seat.

The PowerFilm is an efficient solution in many ways. “It supplies 10 kW/m2 from a 0.004m2 piece of film that is 200-250 microns thick and needed only at the neck,” says Sajic. He notes there are currently 200 shapes that can be used to customize saddle trees, “but with our system, you only need, maybe, five or six generic shapes, and then simply heat them to tailor and match the horse you’re riding.”

LaminaHeat has demonstrated a number of other PowerFilm applications, including de-icing of wind blades. Sajic notes this is an interesting engineering problem, “because the tip speed of these long blades can easily exceed 70 m/s, so if you put a heater there it cools down right away. We’ve demonstrated a proactive system that prevents ice from forming using a very low-mass insert [20 g/m2] embedded into the glass laminate.”

The PowerFilm’s low-CF mass and insulation from glass fiber prevent it from attracting lightning strikes. “There are companies spending millions on carbon nanotubes,” says LaminaHeat’s VP sales and marketing for North America Marc Anderson, “but we have a low-cost, efficient solution that works now.”

Related Content

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreRead Next

Heated composites

LaminaHeat enables heated composite tools and new opportunities for composites via multifunctional structures.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More