Heated composites

LaminaHeat enables heated composite tools and new opportunities for composites via multifunctional structures.

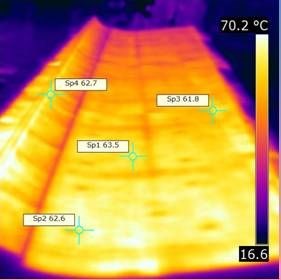

LaminaHeat's PowerFilm and PowerFabric products can be integrated into composites enabling surfaces to be evenly heated up to 232°C. SOURCE: LaminaHeat.

Multifunctionality has become a mantra among aerospace OEMs and advanced manufacturing proponents. “Airbus needs more from the material than pure strength per kilogram,” explained Dr. Thomas Kruse, Airframe Design - Research & Technology at Airbus, in a 2013 presentation. The goal is to replace discrete functional layers (e.g. bronze mesh for lightning strike protection) with capabilities integrated into the composite materials, such as conductivity, vibration and acoustic damping, erosion resistance, structural health monitoring and de-icing. Composites offer real potential to achieve such multifunctional structures and are being developed for a wide range of applications.

LaminaHeat LLC (Greenville, SC) has demonstrated heated composite tooling and structures using its PowerFilm and PowerFabric materials. PowerFilm is a thin layer of carbon fiber (CF) insulated with a polymer and incorporating copper contacts that efficiently converts electricity into heat. Though only 100 microns thick, it can generate up to 10 KW/m2. This is roughly the same heat as 3 gas fires from 1 m2 of film, but converted with 99% efficiency vs. only 80% for gas flame, according to technology developer Peter Sajic.

The dense, homogeneous CF network used provides uniform heating via a lightweight, flexible and damage-resistant material. PowerFabric sandwiches this veil between woven fabrics for an expanded range of flexibility and applications. Temperatures up to 232°C can be maintained across large structures or localized in specific regions. A range of polymer and product finishing options allows manufacturers to laminate these products into composite structures.

Norco GRP Ltd. produced a multi-zone heated CFRP tool for curing 18m long wind blade tips using PowerFilm. SOURCE: Norco GRP Ltd.

Norco GRP Ltd. (Poole, Dorset, UK) has demonstrated the use of PowerFilm in an 18m long carbon fiber composite tool for Blade Dynamics’ (Southampton, UK) manufacture of tips for its 75m blades being tested in 6MW offshore wind turbines. Norco used ZPREG carbon/epoxy prepreg from Cytec Industrial Materials (Heanor, Derbyshire, UK) and PowerFilm to fabricate a multi-zone heated tool with external computer temperature control. Norco describes the tool as providing almost instant controllable heat exactly where it is needed. Norco has since used this technology for a number of other applications.

A variety of horseriding saddles now use carbon fiber composite trees — i.e., the frame around which the saddle is built. For example, WOW saddles use a patented “Y” shaped composite frame (left) and Pampa Saddles has a new carbon/Kevlar model.

SOURCE: WOW Saddles and Pampa Saddles.

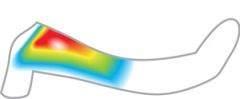

A CF/polyethylene terephthalate (PET, or thermoplastic polyester) PowerFilm has been used recently in the world’s first fully adjustable saddle tree, enabling the structure to be heated and reformed to adapt to changes in the horse’s body shape without disassembling the saddle. A battery supplies current to the saddle tree, which is heated to PET’s softening point, after which a simple adjustable clamp is applied to conform the tree to the new shape. The process, which takes a maximum of ten minutes, can be performed while the saddle remains mounted on the horse and may save thousands of dollars per year. The technology is being heralded as revolutionary in the equestrian world.

PowerFilm is being used in the award-winning Barnsby i-Tree saddle, which can be easily and repeatedly adjusted. SOURCE: www.hay-net.co.uk and www.horsetalk.co.nz .

Citing work at the Massachusetts Institute of Technology (Cambridge, MA, US) and Battelle (Columbus, OH, US) to develop carbon nanotube-based systems for heating and curing composites and aircraft wing de-icing, respectively, LaminaHeat’s VP sales and marketing for North America Marc Anderson comments, “We already have a product that can do both of these.” LaminaHeat is working with a variety of aerospace manufacturers and research organizations to complete demonstrations of PowerFilm and PowerFabric for de-icing applications, and sees much broader applications.

Related Content

Carbon Mobile, SABIC to develop, deploy advanced carbon fiber in connected devices

Collaboration aims to deliver the next generation of thinner, lighter, stronger and more sustainable composite materials used in consumer electronics and automotive industries.

Read MoreSyensqo provides PARA resin for Artiphon musical instrument

Artiphon has chosen Syensqo’s Ixef PARA fiber-filled resin in the production of Chorda, its custom handheld electronic musical instrument.

Read MoreCycle Inspect, UNSW investigate carbon fiber bicycle damage

The collaborative research initiative will explore the prevalence and impact of structural damage in carbon fiber bicycles currently in use by the general public, assessing the magnitude of the issue and raising awareness.

Read MoreGlass fiber-reinforced Akulon RePurposed recyclate enables Ahrend sustainable office chair

Envalior 30% glass fiber-reinforced Akulon RePurposed material helps Ahrend achieve lighter task chair with closed-loop value chain and reduced emissions.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More