Technical University of Munich researchers explore using algae to make carbon fiber

The process uses algae to convert CO2 from the atmosphere and manufacturing exhaust into algae oil, which is then used to produce polyacrylonitrile (PAN) carbon fiber precursor.

Source | Technical University of Munich

Technical University of Munich (TUM, Munich, Germany) researchers have been working to develop a process that uses halophilic algae, algae that thrive in high salt concentrations, to remove CO2 from the atmosphere and subsequently to make carbon fiber.

According to Thomas Brück, who heads the project along with a team at the Algae Cultivation Center of the Technical University of Munich, the process converts atmospheric CO2 into biomass, an organic material used as a renewable energy source, and, in a subsequent stage, algae oil. The algae oil is produced by a nutrient depletion phase where nitrogen is limited in the cultivation medium, triggering the accumulation of lipids.

“We then hydrolyze the algae oil so that we actually split the free fatty acids from the glycerol backbone,” explains Brück. The fatty acids are then used to generate biofuels, chemicals for the lubricant industry or thermoplastics, he says. The remaining glycerol residue is turned into acrylonitrile, which is polymerized to yield polyacrylonitrile (PAN), the precursor for approximately 90% of today’s carbon fiber production.

While the PAN precursor can be pyrolized via standard means, TUM has also developed a pyrolysis process that carbonizes the PAN fibers using parabolic solar reflectors — curved solar mirrors — in order to yield carbon fibers in a CO2 neutral manner.

“We do the pyrolysis in focused glass tubes in the center of those mirrors,” says Brück. “There you can actually generate temperatures up to 3,000ºC, and with that technology, you’re completely emission-free and also cheaper because you’re using sunlight.”

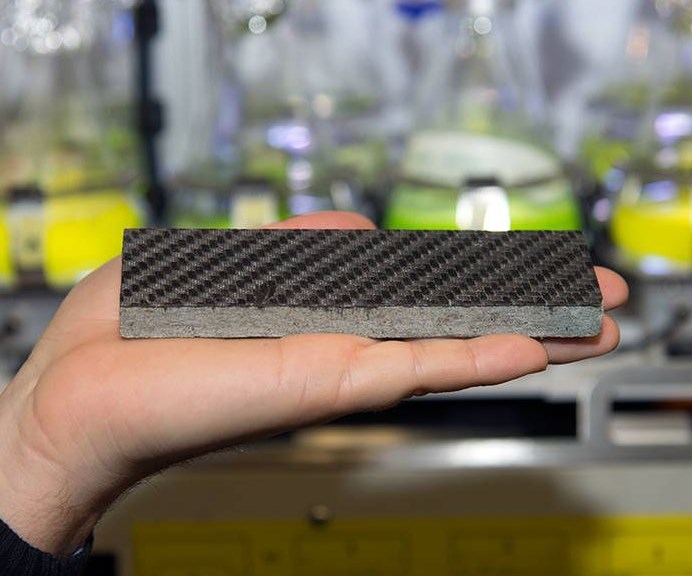

According to Brück, the carbon fiber created using the algae-based PAN has the same chemical composition as classical carbon fibers currently in use today and the same physical properties as those carbon fibers that come from petroleum resources.

“And since we can combine the thermoplastics that we generate from the fatty acid part with the carbon fiber, we can actually now do 3D printable carbon fiber composites,” says Brück. TUM is also currently working with a partner to develop CO2 negative building materials such as carbon fiber composite-reinforced granite from the algae-based carbon fiber.

Related Content

-

Toray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.

-

Inha University incorporates SwiftComp simulation software to virtually test composites

AnalySwift’s SwiftComp tool aims to mitigate the burden of costly experiments and enable accurate testing of woven and braided composite structures.

-

New online training course targets prepreg basics

JEC World 2024: Composites Expert highlights how its E-Learning Composites Academy platform supports flexible industry learning with new courses developed with Stelia Aerospace North America.