Travel through the Charlotte, NC, US, metropolitan area, where Composite Resources is situated, and to this day you will find abandoned textile mills dotting the landscape. Economically, the 1970s and 1980s were unkind to this region, as textile manufacturers moved their operations to other parts of the world. As recently as 2010, local newspapers reported little change in the jobless rate — 15.7% in York County, SC, just south of Charlotte, compared to 9.5% nationwide.

But positive economic signs began emerging in York County during the past decade, and today you will find vibrant and growing industrial parks, home to numerous manufacturing success stories. Composite Resources counts itself among them. The revitalization of this region, the training of a new composites workforce, and interestingly, the locale’s passion for racecar driving, are intertwined with the founding and growth of Composite Resources and distinctively color the company’s corporate culture.

Composite Resources describes itself as a “full service composite engineering and manufacturing company.” Founded in 1992, the company employs more than 50 people at its 55,000-ft2/5,102m2 facility in the mid-sized city of Rock Hill, SC, US, about 15 miles south of Charlotte. Next door, another 50-plus people staff two sister companies in a 60,000-ft2/5,574m2 facility: C.A.T. Resources, maker of the Combat Application Tourniquet (C-A-T), a one-handed tourniquet that has been issued to more than 1 million military personnel since 2004; and CORE autosport, which has fielded teams in both prototype and production-based motorsports since 2010. CORE autosport has also helped to feed one of the passions of CR founder, Jonathan Bennett.

Not coincidentally for Bennett, 1992 marked the launch of both his road racing career and his composites industry brainchild. Bennett had been working for a large engineering company but decided that year to go out on his own as a composites engineering consultant, initially operating out of his garage, so that he would have the opportunity to work more in the automotive arena. The business grew and, by 2001, Composite Resources was ready to avail itself of attractive business incentives offered by the State of South Carolina, and built its current facility. The second building that houses CR’s sister companies was added in 2010.

As is true of many industrial parks in revitalized southeastern US cities, the tree-lined boulevard entrance to Tech Park South, just off one of Rock Hill’s main avenues, is marked by an unassuming brick and metal sign. From there, the approach to Composite Resources feels less “industrial” and more “park.” Just beyond its small parking area and front lawn, the company’s one-story, U-shaped building sits behind its own greenery-surrounded brick and metal sign — this one also displaying the company’s ISO9001 and AS9100D certifications. The main entrance to the building is located at the end of the wing nearest the parking lot entrance.

Niche of opportunity

One testament to the way in which Composite Resources began is a display wall that welcomes visitors into the facility lobby. The diverse collection of products exhibited here, ranging from an orthopedic spar to a carbon fiber cooling duct, often became part of CR’s story because of the company’s ability to engineer composite solutions to unusual engineering problems.

“We were more of a job shop at first, focused on prototypes,” recounts Mel Clauson, CR’s director of business development. “And we will still look at interesting opportunities that come in,” he continues. “This is what you get with a private company that’s smaller and entrepreneurial. If it looks interesting and potentially profitable, we may buy a couple machines and make it happen.” Clauson points out that the decision path for buying new equipment is very short for a private company like Composite Resources, because it is not tied to the kind of annual corporate budget that constrains capital investment for larger manufacturers.

This rapid response capability begins to define the niche in which CR has built its business. As a Tier 3 manufacturer with a design-build emphasis, Composite Resources has positioned itself between “smaller players, who are great at R&D and prototyping, and larger players who really want to focus only on production,” explains CR COO Morgan Brady.

“We really fill this void,” he continues. “We produce quick-turn prototypes, going from CAD to parts in a matter of days, yet when such a program is ready for production and the client needs 7,000 parts per year, we have the size to support that as well.” Clauson agrees. “What a big business doesn’t want or can’t do, we can do,” he says. “I think that’s where Tier 3s survive, on the opportunities afforded them by larger companies.”

Though the business has experienced modest growth for most of its existence, in early 2016 Brady took stock of CR’s operations and decided to develop a more deliberate growth strategy. Prior to joining Composite Resources, Brady had worked as an engineer in motorsport, and this background led to a partnership with Bennett to start a race team — now CORE autosport — in 2010. By 2015, when Bennett was ready for a diminished role in CR’s day-to-day operations, Brady recognized the opportunity that Composite Resources might afford him to pursue his passion for business. He saw great upside potential for the company. “I asked Jon to let me have a financial stake and run the company,” Brady recalls. “He gave me the keys and let me have a go at it starting in 2016.”

Within a few months, Brady had identified the aerospace sector as a potentially great source of growth. Clauson, an aerospace veteran, was tapped to join CR that year. He notes, “We’re diving into aerospace and defense at a time when this whole space is very busy and there are lots of opportunities.”

CR’s efforts in aerospace and defense have quickly begun to pay dividends. Clauson reports that the company added 12 positions in the past six months. The increased work load has also warranted major equipment purchases this year, including a new 5-axis machining center and two presses.

Key to this early success is the fact that CR is vertically integrated. “From those initial designing/scheming sessions on into production — cutting, kitting, moldmaking, inspection, coatings, machining — it’s all here,” Brady emphasizes.

Verticality

As our tour begins, behind the reception area and past offices for the purchasing department, we enter a small hallway. Clear glass panes make up the top half of the hallway’s walls, providing a view into CR’s engineering workspace on one side and quality/testing area on the other. Representing one end of CR’s vertical capabilities, a team of six engineers brings the design of composite components to fruition. Their workspace consists of an open floor plan with variable-height desks, arranged in pods to facilitate collaboration. A dedicated conference room for the engineers is adjacent to the workspace, also enclosed with glass walls for a light, open environment.

Demands on the engineering team run the gamut. “On one end of the spectrum,” Brady illustrates, “a more established aerospace client like Rockwell often has a fairly defined specification — a drawing, maybe the materials and procedures they want us to use. On the other end of the spectrum, a client less familiar with composites, or someone with a metal component they want to convert to composite, may simply ask us to make that happen. We can support that whole range.”

The rest of the plant tour exhibits CR’s capacity for vertical servicing, from design to tooling, to post-cure machining and painting as well as coating. Being vertically integrated helps CR control its scheduling and quality, as well as its profit margins, Clauson points out. But perhaps more significantly, it is an attractive feature to the company’s customers. “A prospective customer walks in, and they want to be able to write one purchase order,” he points out. “And they want their questions answered; they don’t want to hear that you have to call another supplier.”

A staff of stakeholders

We emerge next into a wide corridor situated on the front side the U-shaped building’s base wing. To our left is the facility’s front lawn and parking area, and to our right, a glass wall with a view of the main manufacturing floor. This corridor hosts monthly company-wide luncheons, where tables and food are brought in and the owners talk about how CR is doing — new customers and work, financial status, etc. “The idea is to engage people,” Clauson says, “because if they’re engaged, you start to get that discretionary effort from people. They care more about our products. They’re happier, and they stay longer.”

Beyond the open corridor, we reach a climate-controlled hand layup area at the end of the building’s far wing. This area includes as many as a dozen work stations, depending on the work schedule. One important consideration as the company assigns staff members to various projects is that both aerospace and non-aerospace components are part of the job mix. “You don’t want to burden the non-aerospace parts with aerospace overhead,” Clauson mentions, “but you want to make sure the right attention is paid to aerospace parts. We’ve set up teams to address this.” Developmental articles are typically assigned to teams with the most experienced workers. Hand layup of industrial production parts is often a good starting point for new staff members.

Composite Resources has reached a size for which “we’ve run out of ‘friends and family’ and must hire new people,” Clauson says. “Finding people with experience is difficult, but you can train people to do this kind of work.” Machinists, on the other hand, must bring some level of experience. The nearby technical college includes a machine tooling program, which helps feed the pool of qualified applicants. Staffing will become an even greater focal point for the company if a second shift is added. This option is under consideration to better leverage CR capital equipment.

We pass from the hand layup area through a manual trim area with downdraft tables, and on to the main shop floor, which spans the back side of the building’s main wing.

Racecar philosophy

Moving through this main shop area, it is easy to surmise that preparedness is a core value of Composite Resources, as we come across two autoclaves (one from ASC Process Systems, Valencia, CA, US; and the other from American Autoclave Co., Jasper, GA, US), two Kolpak (Parsons, TN, US) freezers (a walk-in, 5 ft by 12 ft, and a drive-in, 25 ft by 25 ft), and two Global Finishing Solutions (Osseo, WI, US) Concept paint booths (one enclosed and one open-faced). Equipment for a mix of manufacturing processes — also often found in pairs — occupies the rest of the main floor. Though the company welcomes work for both pieces of equipment in each pair, Clauson explains that the idea is to ensure they make delivery dates. In fact, at the company-wide luncheons, the owners have admonished the team, “In the entire history of racing, a start flag has never been delayed because somebody wasn’t ready.” The paired equipment ensures readiness for each “race” the shop floor undertakes.

CR’s larger autoclave is 17 ft long — long enough to accommodate larger components. The company is considering additional autoclaves as part of its capital plan, anticipating ongoing autoclave work. “Even though there’s a lot of work being done with out-of-autoclave processes, there’s still a lot of autoclave work out there,” Clauson believes. “And because of qualified material systems, I think there will be for many years.”

Equipment on the main shop floor naturally is organized by process type. To our right past the autoclaves and freezers, several staff members are using the two Wabash (Wabash, IN, US) presses to compression-mold carbon fiber/epoxy brackets designed to hold video monitors on airplane seat backs. Clauson points out, “Presses are very robust pieces of equipment. As long as you clean up the control system, they continue to work well.” The press workload is nearly full, he reports, even though they came online a mere six months ago.

Beyond the presses, two McClean Anderson (Schofield, WI, US) WLH-1-2-4M filament winders are fabricating filter housings for ultra-clean water systems. CR winds the main section of these housings, then winds a flange area. The outside diameter and flange area are then machined to specification and coated.

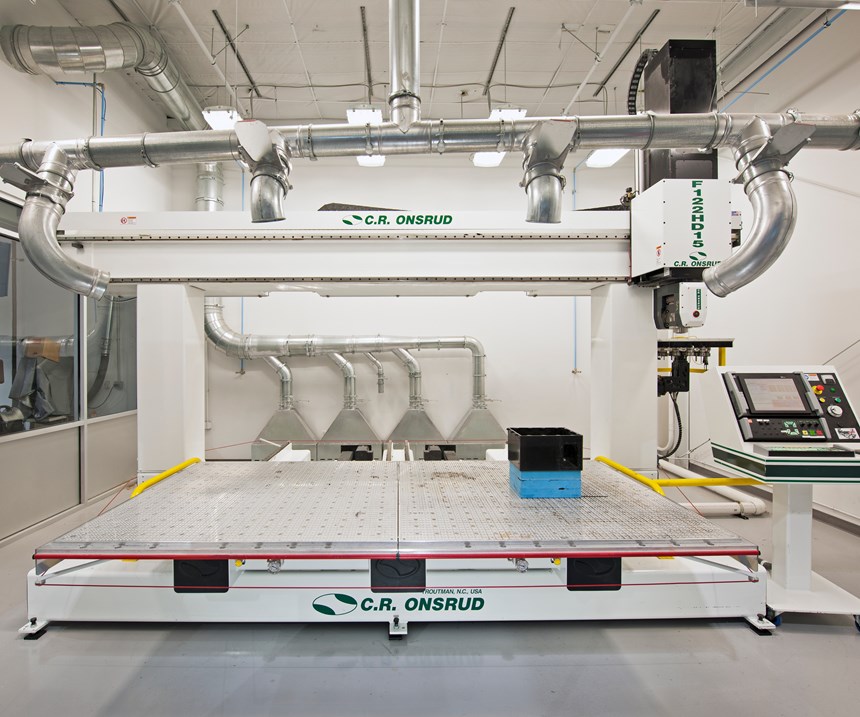

To our left stand the two 5-axis machining centers, as well as several routers and turning centers, a gantry mill and a grinder. CR added its second Haas 5-axis machining center this year. The company machines its own products, completing post-cure trimming and drilling, for example, and also gets machining business from other companies. “Traditional metal machine shops are scared of machining composites,” Clauson has found. This reluctance creates additional opportunities for CR to fill its machining capacity, and the company is getting more and more inquiries about machining. A high-end machining center may be purchased in the near future.

The two C.R. Onsrud (Troutman, NC, US) machining centers feature a 5-by-10-ft bed, which enables CR to machine fairly good sized parts and tooling. The company uses an outside supplier for steel, Invar or other heavy metal tooling, but it creates all other tooling in house, including plugs, masters and molds, made from tooling materials ranging from lighter metals like aluminum to RenShape (Huntsman Advanced Materials, The Woodlands, TX, US) “blue blocks” and honeycomb core. “We do a lot of work with blue block tooling,” Clauson reports. “It’s inexpensive and really good for prototyping and short runs.” He notes that customers sometimes think they need metal tooling, but “if they only want five or 10 parts and they may change the design, blue block is faster and cheaper, and we can deliver parts pretty quickly.”

Near the machining centers, several aramid parts, designed to house electronics and serve as radomes on military vehicles, are queued for trimming. Nearby, a glass-enclosed office space houses computers used primarily for CNC coding. On a desktop in this area rests an interesting prototype that represents another burgeoning application area: a carbon fiber/epoxy leg for a drone. Composite Resources engineers designed this one-piece leg based on the drone maker’s initial design, which was comprised of 17 pieces. Part consolidation is often a more significant factor in drone applications than lightweighting, Clauson notes, as is the vibrational damping that composites offer.

Stock in trade

The two large workrooms that we enter next, located at the back of the U-shaped building’s near wing, are dedicated to processes that support steady production work the company performs for its customers. “We have a good mix of legacy versus new projects and equipment,” Brady notes. “Several clients have been around since Jon was in his garage.”

In the first room, two Gerber Technology (Tolland, CT, US) DCS 2500 ply cutters, 6 ft by 22 ft, are creating ply patterns from carbon fiber/epoxy prepreg. Between prepreg and the towpreg used on the filament winders, carbon fiber/epoxy materials make up about 75% of Composite Resources’ products. Off to one side of the cutters is a small product inventory area. On the day of our tour the shelves hold several lavatory sinks for commercial airliners, which CR manufactures from glass fiber/polyester, then gel coats the surface and post-forms the metal bowl in place. On the floor nearby sits a forming fixture for LEAP (CFM International, Cincinnati, OH, US) engine blades with a rather complex geometry. “The LEAP blades are really thick on one end and go down to a razor edge on the other,” Clauson explains, “so the fixture helps form the part’s preform before it is placed into an RTM mold.” CR manufactures the fixtures from scratch, including the aluminum master.

The second room is dedicated to roll-wrapping of tubes. Through its history, CR has manufactured more than 100,000 seat tubes for commercial aircraft seating. Equipment in this room includes two CDi (San Diego, CA, US) M880 FB roll wrappers with 10-ft platens, three CDi M700C tape wrappers with 12-ft tape carriage travel; a CDi M3300 Mandrel Extractor with 15-ft travel; and several Grieve Corp. (Round Lake, IL, US) and DK Ovens (Rialto, CA, US) programmable ovens with Watlow (St. Louis, MO, US) controllers.

From these rooms, we return past a conference room and back to the lobby, where our tour ends.

To the future and beyond

While strategic planning for the next several years for Composite Resources occupies most of his time, Brady also entertains more visionary aspirations when time permits. “Beyond five years, we expect commercial aerospace to be the bread and butter of our business,” he says. “But I’m really interested in the category of ‘future flight’ — the Uber flying taxi program, commercial and interplanetary space flight, for example. That word, ‘aerospace,’ is going to grow to encompass a much broader field going forward, and that’s what we’re really excited about.”

For today, though, Brady is happy to reap the fruits of CR’s thriving niche. He points out that the company’s experience seems to counter the prevailing view of the current market. “The narrative in a lot of aerospace today is cost pressures and squeezing of suppliers,” he says. “If you read a lot of the press, it doesn’t sound like a great place to be. But we’re a great success story.”

Related Content

CompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreCOMPINNOV TP2 project promotes use of thermoplastics in aerospace

Completed in 2023, COMPINNOV TP2 explored thermoplastic composites, enhancing the understanding between prepregs and production methods to foster the potential for French aerospace innovation.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More