Thermoplastic composite pipe goes deep

Magma Global has already made a name for itself with the manufacture of its PEEK-based m-pipe for subsea oil exploration. Now it can go as deep as 10,000 ft/3,000m at pressures up to 15 ksi.

Share

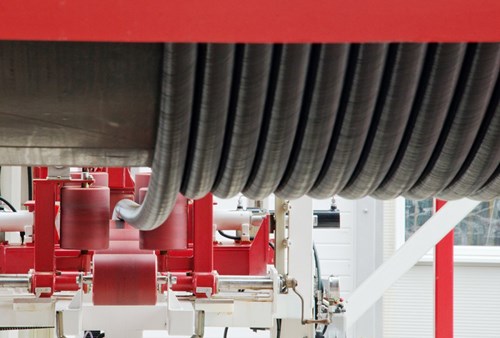

Magma Global's latest PEEK-based thermoplastic composite m-pipe can be deployed for subsea intervention (oil extraction) to depths of 10,000 ft/3,000m at pressures up to 15 ksi/15,000 psi.

Magma Global Ltd. (Portsmouth, UK), in an effort to reduce cost and risk in offshore oil extraction, has developed a new version of its well-known flexible thermoplastic composite m-pipe technology. It's the company's largest and longest VICTREX polyetheretherketone (PEEK)-based m-pipe structure ever, achieved with the support and expertise of Victrex Plc (Cleveleys, UK). This m-pipe can be deployed to depths of 10,000 ft/3,000m and can handle pressures of up to 15 ksi/15,000 psi. The composite pipe combines VICTREX PEEK, high-grade carbon fiber and S-2 glass fibers to form a reliable subsea intervention line that meets the demand for a hydraulic pumping system that can handle high pressures and high flow rates.

Magma is offering its m-pipe and integrated deployment package as a vessel back-deck system for rapid hydraulic light-well intervention. The Magma deployment system has a modular reeler with m-pipe intervention line pipe handling system, built-in tensioner, level wind, controls cabin, hydraulic power unit, installation platform and winch, for rapid pipe deployment and retrieval. The m-pipe delivers low fatigue, good buoyancy in fluids and high resistance to corrosion compared to steel pipe.

“In oil and gas exploration, the continuous need to extend scope and efficiency motivates us to develop reliable solutions further. In close collaboration with customers we consequently contribute to solve the toughest challenges,” explains Tom Swanson, energy director at Victrex. By specifying high-performance PEEK composites and polymers that Victrex has developed for this program, the m-pipe in the new Magma deployment system offers:

- Capability to handle high temperatures

- Ability to deal with pressures up to 15 ksi

- Deep water capability down to 10,000 ft/3,000m

- Excellent fatigue life for thousands of reliable deployments

- Light weight for ease of installation and reduced pipe stress

- Smooth PEEK bore for efficient and rapid flow of intervention fluids

- Resistance to well completion and stimulation fluids and gases for operational reliability

- Cost reduction and efficiency increase

“Our VICTREX PEEK-based m-pipe and deployment system offers regular, reliable low-cost hydraulic well intervention, and can be rented as a complete deployment package from Magma, on either a short-term campaign or annual contract basis. m-pipe reduces the cost of intervention at a time when the oil and gas industry is extremely challenged on operational costs, and is also striving to achieve efficiency and reliability. The Magma system is designed to minimize mobilization time and maximize vessel utilization by reducing hydraulic pumping time, reducing intervention costs by up to 30%,” says Charles Tavner, commercial director at Magma Global.

Related Content

-

NCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

-

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

-

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

.jpg;maxWidth=300;quality=90)