Victrex Plc

Hillhouse International

Cleveleys, Lancashire, FY5 4QD GB

44 125 3897 700

victrex.com

About Victrex Plc

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Victrex Plc Supplies the Following Products

- Aerospace, aircraft interior

- Aerospace, flight control surfaces

- Aerospace, fuselage/wing

- Aerospace, radomes

- Continuous fiber

- Continuous fiber/thermoplastic resin

- Electrostatic

- Fabric

- Laminate sheets, solid

- Other composite structures

- Other organic fibers

- Polyether ketone family (PAEK, PEKK, PEEK)

- Powder

- Protective

- Tape, unidirectional

- Thermoplastic, short fiber-reinforced

Editorial, News, and Products

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

MiniLab consortium produces first full-scale thermoplastic composite hydrofoils

Project advances toward first recyclable foils for ocean racing, part of “Infinite Foil” finalist for JEC Innovation Award 2025.

-

Composites end markets: Boatbuilding and marine (2025)

As 2023-2024 consumer demand slows, boat and marine vessel manufacturers continue to focus on decarbonization and new technologies using composites.

-

Proving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

-

Victrex offers commercial availability of LMPAEK granules, powders

Elevated performance and process efficiency for composites and additive manufacturing processes is demonstrated through the thermoplastic polymers.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Fraunhofer IWS completes MFFD longitudinal fuselage joint using CONTIjoin technology

Thermoplastic composite upper and lower half shells for the Multifunctional Fuselage Demonstrator were welded using CO2 laser over a total length of 8 meters.

-

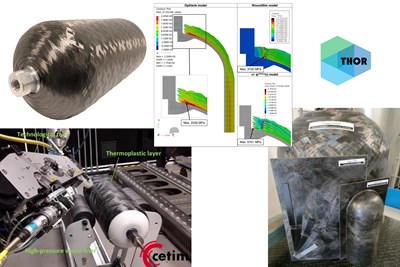

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

Daher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Tool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

DLR completes MFFD upper shell skin layup

Eight-meter-long CFRTP fuselage skin was achieved via laser-heated in-situ consolidation, with stringers, frames and cleats to be welded.

-

NCAMP qualifies Victrex LMPAEK thermoplastic material system

Novel Victrex AE 250-AS4 UD tape has been approved for publication in the NCAMP allowables database for use in aerospace programs.

-

Plant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

-

SPE Automotive Division names 36 finalists for annual Automotive Innovation Awards Gala

Category and grand award winners selected by the Blue Ribbon judging round Oct. 1 will be announced during the gala on Nov. 10, 2021. Submissions are described below.

-

Out-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

-

Victrex launches LMPAEK polymer grade for 3D printing

Victrex AM 200 improve melt extrusion by filament fusion (FF), direct granule extrusion, and laser sintering processes and enhances z-strength and interlaminar strength.

-

Victrex, Electroimpact achieve thermoset AFP speeds using thermoplastics

Using Electroimpact’s AFP technology and Victrex’s low-melt PAEK prepreg tape, the companies report laydown speeds of 4,000 inches per minute.

-

Manufacturing the upper half of the Multifunctional Fuselage Demonstrator (MFFD)

Proving industrial reliability for low-cost thermoplastic composites production using AFP in-situ consolidation, as well as continuous ultrasonic and resistance welding.

-

Future composite manufacturing - AFP and Additive Manufacturing

TU Munich symposium explores how these technologies are merging and reviews R&D that is creating a path forward.

-

Aviation research program kicks off for continuous complex composite profiles

InPro project combines blow molding technology with Continuous Compression Molding (CCM) process for efficient, sustainable continuous composite profile production.

-

Victrex, Daher, attain next-gen thermoplastic aircraft panel milestone

The developed panel is a 176-ply laminate, 32-millimeter-thick composite structure and uses Victrex AE 250 PAEK-based thermoplastic composites.

-

3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

-

Future Composite Manufacturing virtual symposium for AFP and AM

The virtual symposium, held Sept. 9-10, 2020, will focus on current state, trends and opportunities for automated fiber placement (AFP) and additive manufacturing (AM).

-

Proving out LMPAEK welding for Multifunctional Fuselage Demonstrator

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test LMPAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

-

Victrex optimizes PAEK polymers for AM platform

The University of Exeter has commissioned an EOS P 810 laser sintering platform, for use with Victrex high-temperature PAEK polymers.

-

Overmolded hybrid parts open new composites markets

A process that combines continuous carbon fiber-reinforced PAEK with chopped fiber/PEEK overmolding is making inroads in the aerospace market. Parts that previously could not be produced cost-effectively from composites can now be made at less cost than their metal counterparts.

-

Rocket module manufactured with in-situ consolidation survives first flight test

A carbon fiber-reinforced thermoplastic (CFRP) module developed at the Technical University of Munich survived its first launch — and a “hard landing” — in March.

-

Injection-forming for high-performance, unitized thermoplastic structures

Combining braided tape, overmolding and form-locking, herone produces one-piece, high-torque gear-driveshaft as demonstrator for broad range of applications.

-

Thermoplastic composites: Poised to step forward

The evolving role of thermoplastic materials and processes and their future in next-generation commercial aircraft.

-

Victrex and Bond partner for 3D printing PAEK parts

The companies are collaborating to combine Victrex’s PAEK material expertise and Bond’s 3D printing technology for an accelerated pathway to 3D-printed PAEK part production.

-

Thermoplastic composite pipe on the rise in the deep sea

Demonstrators, pilot programs and qualification efforts are paying off as thermoplastic composite pipe (TCP) makers take orders for deep-sea oil and gas applications.

-

SFS Intec, TxV to redesign aircraft bracket using thermoplastic composites

Originally made from aluminum, the new bracket will be made of VICTREX AE 250 composites overmolded with VICTREX PEEK polymer.

-

JEC World 2019 preview: Victrex and Coriolis

Victrex (Thornton Cleveleys, U.K., 5/S29) and Coriolis Composites (Queven, France, 6/A32) are announcing cooperative work they did with thermoplastic unidirectional tape (TP UDT) prepreg lay-up and consolidation to improve the manufacturing efficiency of composite parts.

-

Surface Generation molding technology selected for Victrex parts-based programs

Surface Generation’s Production to Functional Specification (PtFS) technology manages multiple part areas during processing and drive reductions in the energy consumption, injection processing pressures and cycle times.

-

CFRP module saves weight on rocket design

Taking advantage of carbon fiber/PEEK mechanical and thermal performance, the Technical University of Munich replaces an aluminum rocket module with a 40+% lighter composite alternative.

-

NIAR's NCAMP qualifying TenCate thermoplastic composite

TenCate’s Cetex TC1225 T700GC 12K T1E unidirectional tape is a low-melt polyaryletherketone (LMPAEK) and is part of a broad effort by the National Center for Advanced Materials Performance (NCAMP) to qualify thermoplastic materials.

-

Victrex launches PEEK polymer for cryogenics

VICTREX CT 200 is designed for dynamic sealing applications where gases such as liquefied natural gas (LNG) are stored and transported at cryogenic temperatures.

-

Spirit AeroSystems joins TPRC as Tier-1 member

The TPRC’s membership base has grown to a community of 20 members focused on progressing the use of thermoplastic composites.

-

Victrex and University of Exeter partner on PAEK for additive manufacturing

3D printing collaboration to focus on R&D in the pursuit of the potential of high-performance polymers in additive manufacturing.

-

Victrex launches PAEK polymer solutions for additive manufacturing

Polymer based solutions company unveils high strength material for laser sintering (LS) and filament for filament fusion (FF) with improved Z-strength.

-

PEEK or PEKK in future TPC aerostructures?

Which is better for in-situ consolidated thermoplastic composite primary structures? Materials play a part as to whether a one-step or two-step process will prevail.

-

JEC World 2018: The highlights

JEC World is the composites industry’s largest trade show and did not disappoint this year.

-

Victrex champions thermoplastic composites for aircraft industry

Company believes thermoplastic composites vital to drive aerospace build rates.

-

Testing, use substantiate m-pipe subsea use

Magma Global’s m-pipe, based on high-performance VICTREX PEEK thermoplastic composites, has recently achieved the world’s first qualification for a subsea pipe product under DNVGL-RP-F119.

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Victrex opens new Polymer Innovation Center

Proactive investment in the development of next-generation thermoplastic solutions has now resulted in the completion of the company´s new approximately $13 million (£10 million) Polymer Innovation Center.

-

Preforming goes industrial: Part 2

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

-

Thermoplastic composite pipe goes deep

Magma Global has already made a name for itself with the manufacture of its PEEK-based m-pipe for subsea oil exploration. Now it can go as deep as 10,000 ft/3,000m at pressures up to 15 ksi.

-

New composite pipe designed for extreme subsea oil and gas operations

The m-pipe subsea intervention line is the longest VICTREX PEEK-based solution ever made.

-

JEC World 2016 exhibition and product previews

JEC World 2016 will be held in Paris March 8-10. These are some of the products that will be found at the show.