Windpower 2009 highlights

The show confirmed wind energy’s status as a recession-proof market for composites, but blade manufacturers were put on notice about the need to automate.

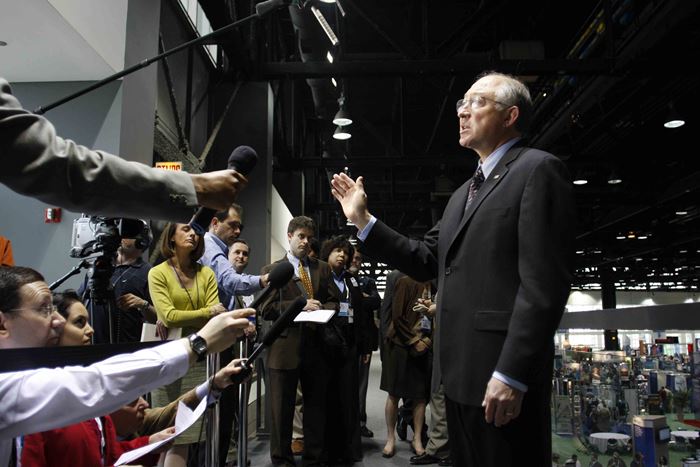

With the allure of federal economic stimulus money in the air, WINDPOWER 2009 attracted high-profile names, including U.S. Department of Interior Secretary Ken Salazar, former presidential candidate General Wesley Clark, energy guru T. Boone Pickins and a host of U.S. governors who see the wind industry as one potential cure for the manufacturing blues that have swept through the upper Midwest of the United States. Held May 4-6 at McCormick Place in Chicago, Ill., and organized by the American Wind Energy Assn. (AWEA, Washington, D.C.), this year’s event was AWEA’s largest ever, attracting 1,280 exhibitors and 23,000 attendees.

21st century blades

Despite the boon wind blades have provided to the composites industry, it was immediately apparent at the show that blade manufacture has become the weak link in the wind turbine supply chain. Rising demand for wind blades is taxing manufacturers’ ability to keep up with demand. Hand placement of reinforcements and other manual manufacturing steps, while common in the molding of other large fiberglass components such as yacht hulls, is now generally considered unacceptable for a component that must be mass-produced in increasing quantities and, according to Roger Cope, president Strategic Business Development Group at MAG Industrial Automation Systems (Hebron, Ky.), behaves more like and has much more in common with an aircraft wing. As a result, says Randy Kappesser, VP/GM, Cincinnati Composites Technologies at MAG, “This industry is very manual, and it’s begging for automation.”

Well aware of the need, MAG and several other composites industry suppliers came to the show armed with plans for automating blade construction (see CT’s special “Work in Progress” report, “Automating wind blade manufacture”).

Representatives from the AEWC Advanced Structures and Composites Center at the University of Maine (Orono, Maine) were on hand with big news: Center director, Dr. Habib Dagher, announced AEWC’s planned expansion of its Advanced Wind Blade Prototyping Facility, for which ground will be broken this summer, with completion expected by year’s end. The facility will facilitate prototyping, optimization and testing of wind blades up to 70m/230 ft in length in an ISO-certified lab environment. Dagher expects the facility to enable blade developers to reduce the design and engineering regime for a new blade from two years to one. He agreed that blade manufacturing is the weak link in turbine production — “We need better automation under controlled conditions” — and thought that proving emerging automation technology would take about two years.

Repair demands, news & new products

Even after automation comes to blade production, there remains in the wind industry a need for blade repair services, and several firms are catering to that need. Wind Energy Services (WES, Independence, Kan.) announced at the show a new office in Worthington, Minn., giving the firm three locations (Kansas, Texas, Minnesota) in the Midwest wind corridor. The company provides pre- and post-installation repair services to wind blades. Before erection, WES repairs aesthetic and structural damage to blades that occurs during transport. After turbines and blades are up and running, WES provides repair following lightning strike and of leading-edge corrosion. The latter occurs on every blade and can cause a 5 to 10 percent power loss per blade.

Ricardo Arellano, operations manager at WES, said the challenge of repairing wind blades is to minimize downtime and thus maximize energy generation for the customer. His firm provides systematic blade inspection and in-situ repair services. The latter requires substantial training not just in the art of leading-edge composites reconstruction, but also in the art of managing the support, ropes, harnesses and safety equipment technicians use to access a blade. Leading-edge repair on one blade he said, usually takes about a day to complete; the company typically lays a glass fiber fabric over the edge and then applies polyester or epoxy, depending on customer specification, followed by in-place vacuum infusion.

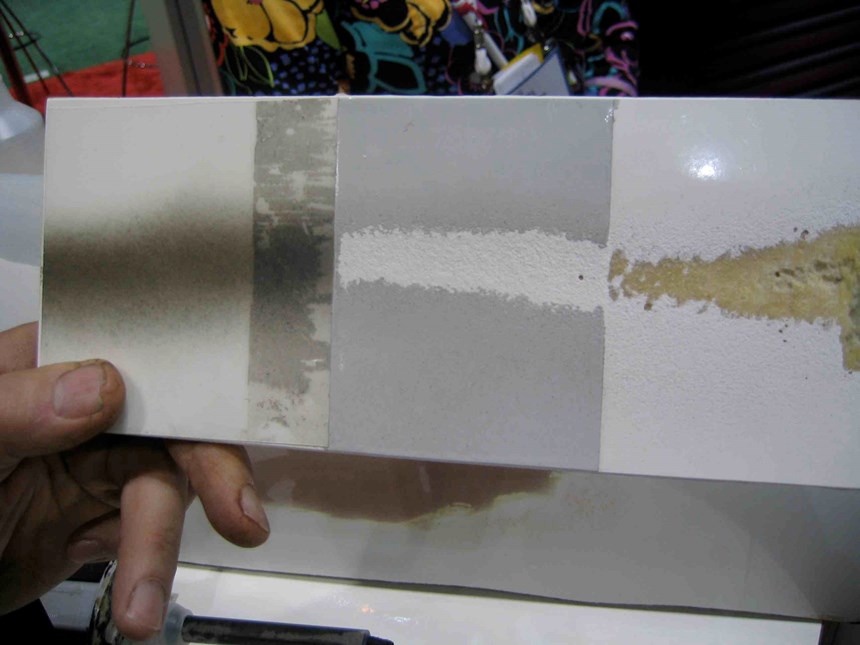

The 3M Co. (St. Paul, Minn.) has its eye on the wind market and is targeting OEMs and repair with products in its new Renewable Energy Division, which looks to provide tapes, films, adhesives and coatings to the wind energy market. Mike Strommen, Wind Energy Segment leader, at the show reported that 3M has had success with the introduction of Wind Tape, a product adapted from a material the company originally developed for aerospace use. Wind Tape is designed to overlay a leading edge following composites repair and provides what appears to be more robust leading-edge corrosion protection. To test the tape, 3M sand blasted a board with three types of leading-edge composite materials; results show that the Wind Tape resists damage best (see photo). 3M says Wind Tape weighs 0.41 lb/yd² and adds about 1 lb/0.45 kg to the weight of a blade when applied to two-thirds of the leading edge. The company also is evaluating films that help reduce blade drag by 7 percent, nanomaterials that enhance resin compression strength, and an epoxy adhesive for blade bonding that is said to provide low exotherm, long pot life and reduced cure time.

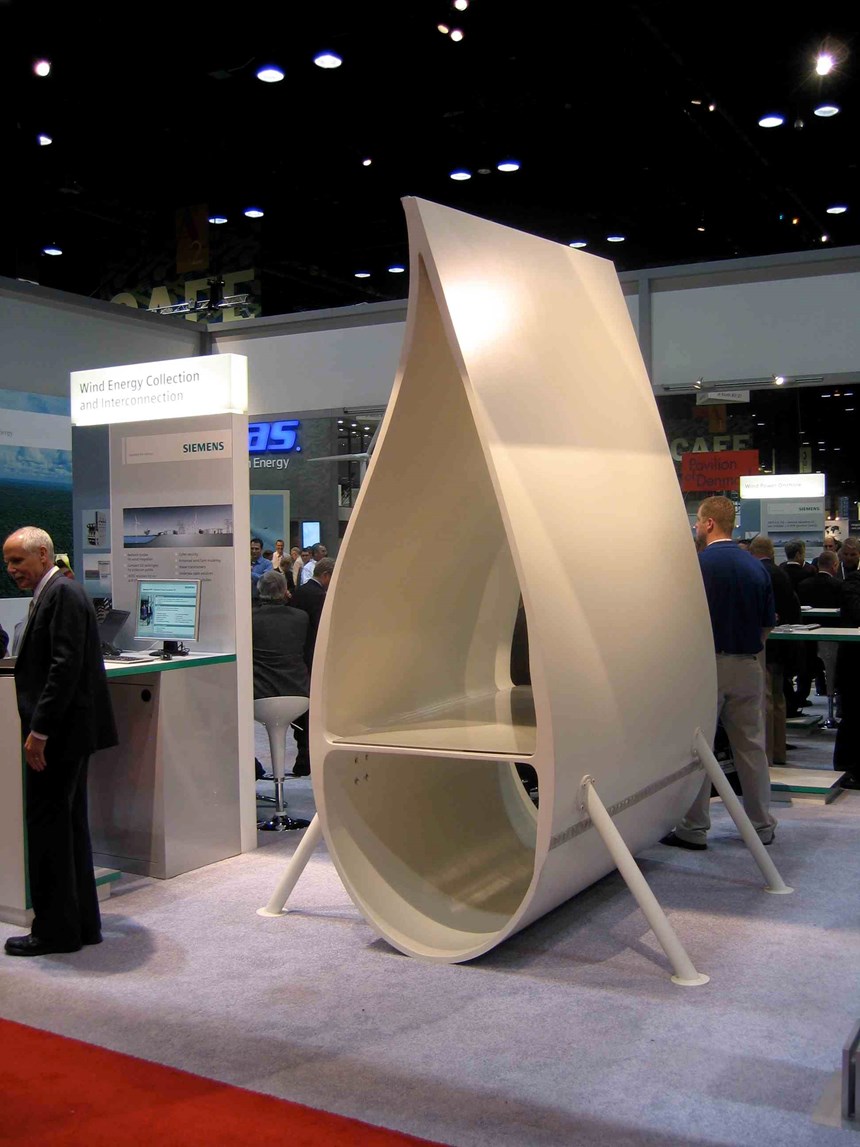

Siemens Energy Inc. (Erlangen, Germany and Orlando, Fla.)attracted a throng to its booth when it announced that construction will begin in August this year on a new nacelle manufacturing facility in Hutchinson, Kan. The $50 million, 300,000 ft² (27,870m²) plant and an adjacent 80,000 ft² (7,430m²) repair facility will eventually employ about 400 people and complements Siemens’ existing blade manufacturing facility in Ft. Madison, Iowa. Shipment of the first composite nacelle structure, designed for Siemens’ 2.3 MW turbines, is expected in December 2010, with production estimated at 650 nacelles per year. The repair facility will be up sooner, using temporary space nearby until the facility is completed.

Carter Products Co. Inc. (Grand Rapids, Mich.) introduced the next generation of its laser alignment system. Designated LP-HFD improvements include more sophisticated projection capabilities and software upgrades. The system provides an interface to CAD design software; layout and production information is extracted from the CAD program and projected to the work area. The system offers 3-D contour templating and, for wind blades, provides sequential layup guidelines for longitudinal and latitudinal sheet material placement, as well as alignment of reinforcements and bracing if required.

Dassault Systèmes’ SIMULIA (Providence, R.I.) business unit emphasized how its ABAQUS finite element analysis (FEA) software can be used to provide simulation for wind blade assemblies. The ABAQUS software works within CATIA V5 Composites Design 3 toolset and provides integration of analysis, design and manufacturing of composites structures.

Henkel Corp. (Rocky Hill, Conn.) introduced at the show Macroplast UK 8340, reportedly the first Germanisher Lloyd (GL)-certified polyurethane adhesive product for the wind power market. It’s a solvent-free, two-component structural adhesive that fully cures in just 8 hours. The adhesive is applied at room temperature and provides exothermic reaction of less than 212°F/100°C. This low-temperature cure is said to minimize the possibility of substrate damage or stress cracking.

Graco (Minneapolis, Minn.) introduced the DC12, a high-volume metering system that delivers up to 26 lb/12 kg of adhesives per minute, and up to 13 lb/6 kg of tooling paste per minute. It features a touch-panel display, allowing for integration into factory processes. The EnGarde ratio monitoring system has optional external flow meters to offer ratio monitoring independent of the ratio and supply system. Dispensing is said to be accurate to within 3 percent.

GS Manufacturing (Costa Mesa, Calif.), which is best known for equipment it supplies to the marine industry, is boosting it presence in wind energy with the XDS 1000-C108, a dual epoxy resin meter-mix dispensing system. It features two metering pump assemblies, two high-flow supply hose sets and two high-flow dispensing valves. Pneumatic drive motors power the pumps; volume and material ratios are controlled by a combination of gears on each pump and motor. The system comes preset with a 100:36 resin-to-hardener ratio, but this can be adjusted to meet application requirements.

25 by 25

On the wind energy policy side, most discussion centered on the Renewable Electricity Standard (RES), a long-term federal energy policy proposed at the show for development and implementation of renewable energy systems. RES was the focus of a panel discussion featuring General Wesley Clark (ret.), director of Emergya Wind Technologies BV (Amersfoort, The Netherlands); Vic Abate, VP for Renewables at GE Energy (Atlanta, Ga.); Ditlev Engel, president and CEO of Vestas Wind Systems AS (Randers, Denmark); Declan Flanagan, CEO of E.On Climate & Renewables N.A. Inc. (Düsseldorf, Germany); and Michael Polsky, CEO of Invenergy LLC (Chicago, Ill.).The RES stipulates that U.S. electric power derived from renewable resources be increased from the current 2.4 percent to 25 percent of the total U.S. requirement by 2025. Most estimates show that this would require 300,000 MW of energy annually from renewables.

Invenergy’s Polsky said, “300,000 MW is very doable. The beauty of renewables is that you only need capital, not fuel.” But GE Energy’s Abate observed that right now GE makes 13 turbines a day and would have to increase that to one turbine every 15 minutes to meet its share of the 25 by 25 goal. Clark noted that the wind industry, which relies on credit to develop wind farms, needs multiyear stability for credit markets to provide sustainable growth. He also repeated an often-heard request that the federal government develop policy to begin a massive upgrade of the national electricity grid to allow wind energy from the Midwest reach population centers. The free market, he said, cannot supply the long-term stability the wind industry needs.

Engel, of Vestas, noted the virtues of American wind in the Midwest and characterized it as too good to ignore: “It’s like going to Saudi Arabia and not drilling for oil,” he said. Indeed, Vestas is not ignoring it, but that a RES would provide a strong incentive. GE’s Abate agreed on the need for an expanded and improved transmission, but also warned that “we can’t let the perfect get in the way of the good,” emphasizing the importance of incremental improvement in wind energy development environment.

Clark finished the panel discussion with a reality check: “The last word is a dirty word: Politics.” Good ideas, he said, are not enough. If the popular voice is heard in Washington, D.C., he said, “we will have 25 percent by 2025.”

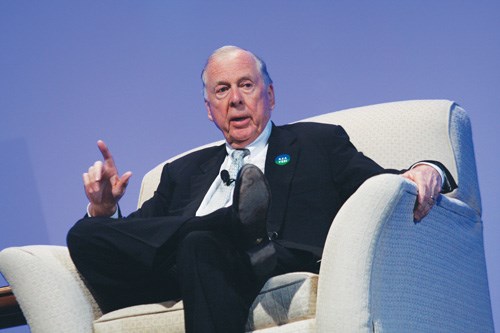

Toward that end, Windpower keynoter Pickins said he wants to generate loud popular support for the RES. The noted oil magnate, whose recent advocacy of wind energy has given the sector a much-appreciated shot in the arm, reviewed the current U.S. oil supply, characterizing it as dangerously unsustainable: Today, 60 percent of U.S. oil is imported, and 70 percent of the world’s oil is controlled by state-owned enterprises. By 2019, if the current trend continues, imports will rise to 75 percent, with 65 percent of that coming from countries now unfriendly to America.

With these data in mind, Pickins has begun a crusade to help the U.S. develop sustainable, domestic energy sources — most notably wind and natural gas. “It’s real hard to come up against my plan,” he observed. “My response is, ‘What’s your plan?’” The alternative, he said, is continued dependence on foreign oil, “and that is a loser.” He encouraged, like the panel before him, folks to contact their representatives in the U.S. Congress: “I can tell you that if I have millions of people with me, then I’m a hell of a lot more effective than just a rich guy in D.C.” He finished optimistically, noting the myriad economic benefits the wind industry can bring to rural America — and the U.S. as a whole: “When we go green, it will be the best economy we’ve ever had.”

Related Content

Toray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.

Read MoreBelzona opens fifth European SuperWrap Training Centre

Global training facilities provide intensive, first-class installer and supervisor training for proper use and application of Belzona composite pipe and tank repair systems.

Read MoreNew online training course targets prepreg basics

JEC World 2024: Composites Expert highlights how its E-Learning Composites Academy platform supports flexible industry learning with new courses developed with Stelia Aerospace North America.

Read MoreFACC Academy begins training, onboarding operations

FACC’s newly launched training platform will address skilled aerospace worker shortages head on, offering more than 250 specialized training courses for its entire workforce.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More