Vabo Composites (Emmeloord, The Netherlands) designs and builds a diverse array of composite structures. The company began in 2001 with several small marine projects, as well as antennas for mobile television broadcast systems, carbon fiber-reinforced manipulator doors and valves for fast-moving palletizing machines and a glass fiber-reinforced front-loader bucket, for which it won a 2015 JEC Innovation Award. The company has also become adept at architectural and building projects and continues to advance its industrial production of ACCEDOO composite ship doors (read “VABO Composites: Dutch innovator excels in diverse applications”) which won a 2017 JEC Innovation Award.

Vabo Composites has also become well known for its expertise as a fabricator of large radar masts for yachts, which house navigation electronics and circuitry as well as exhaust systems from the engines. It has recently completed a 10-by-10-by-10m glass fiber/vinyl ester mast for a 156m-long megayacht, as well as a 10m-tall mast with a 10-by-14m canopy beneath, both made from carbon fiber/epoxy, for a 90m yacht. Normally built from aluminum, these composite masts provide unparalleled structural performance, resist corrosion, help lower the center of gravity on the yacht and, of course, save weight — the first mast, made using glass fiber, achieved a 30% mass reduction and the second, made with carbon fiber, increased mass savings to 50%. “The average weight for this lighter carbon composite structure is 10 kg/m2 while the canopy is supported at only four points,” says Vabo Composites director Arnold Vaandrager. “Aluminum was not an option because of the lightweight and structural performance required.”

Designing to class

“For this type of project, we start by collecting all of the requirements for the structure,” says Vaandrager, “including the operational and environmental requirements, as well as what will surround it and attach to it. We then begin the design process, looking at different materials and calculating the weight and frequency.” Frequency? “Yes, because we are replacing aluminum with much stiffer composites, the structure responds differently to engine and propeller vibrations,” he explains. “So we put the laminate properties into a vibrational analysis.” For the second mast, weight calculations for glass fiber/vinyl ester were still too heavy, which led to the carbon fiber/epoxy construction.

In addition, says Vaandrager, large yachts are typically built “to class,” meaning their design and construction is overseen by a classification society and must meet those regulations. The yachts for both masts discussed here were classed to Lloyd’s Register (London, UK). “Lloyd’s must approve our drawings, construction process and materials,” says Vaandrager. To achieve this approval, Vabo Composites built laminate samples reflecting the proposed materials and process, and then tested these to prove the design properties to Lloyd’s. Vaandrager explains: “They can look up aluminum and steel properties, but with composites, we are making the material as we make the structure, so we have to show what the properties will be.” Then, throughout the fabrication of the masts, Lloyd’s performs checks to prove that Vabo Composites has followed the laminate cure cycles and other process steps as specified. “We also have workshop approval to Lloyd’s,” Vaandrager adds. This certifies that quality assurance processes are in place and followed.

With materials, design and processes approved, Vabo Composites began engineering the necessary molds and buying materials. “After engineering is finished, these masts typically take six to seven months to complete,” says Vaandrager.

Multiple molds and parts

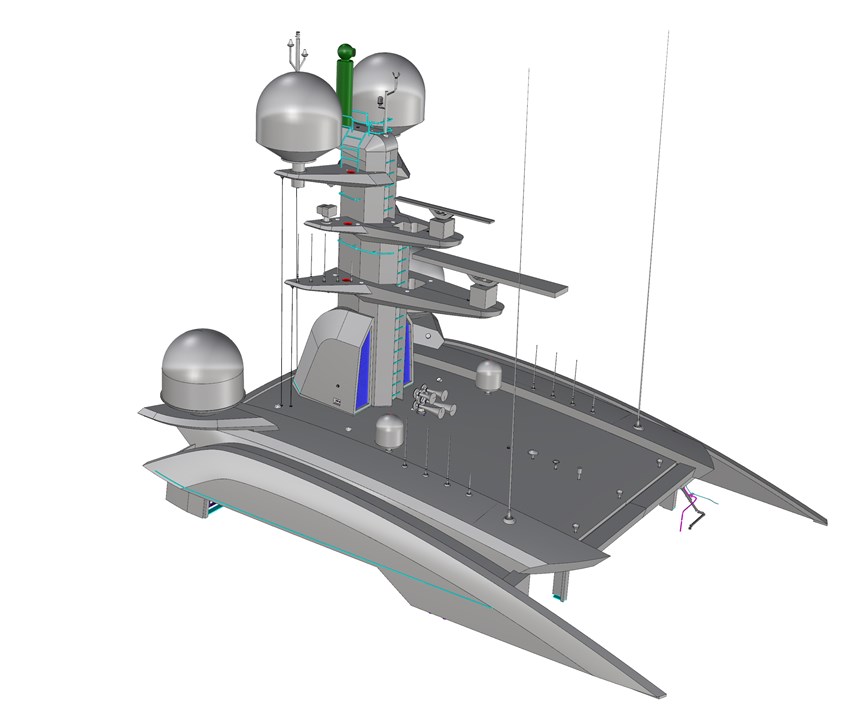

The first step was to make the molds (Step 1). The design for the glass fiber/vinyl ester mast comprised two “L”-shaped legs, attached to form a “T,” from which four platforms extend perpendicularly — three forward and one rearward (see Fig. 1 and Step 11). The carbon fiber/epoxy mast design combined two semicircular uprights with three shelves attached for supporting radar domes, open-array radar scanners (the long bars that spin on a central support), antennas and other electronics (Fig. 2).

Ten molds were used for the glass fiber/vinyl ester mast, while the carbon fiber/epoxy mast required six molds; the canopy was made in a single 10-by-14m tool. Vabo Composites machined these molds from tooling foam and paste, attaching support structure as required by the weight and size of each part.

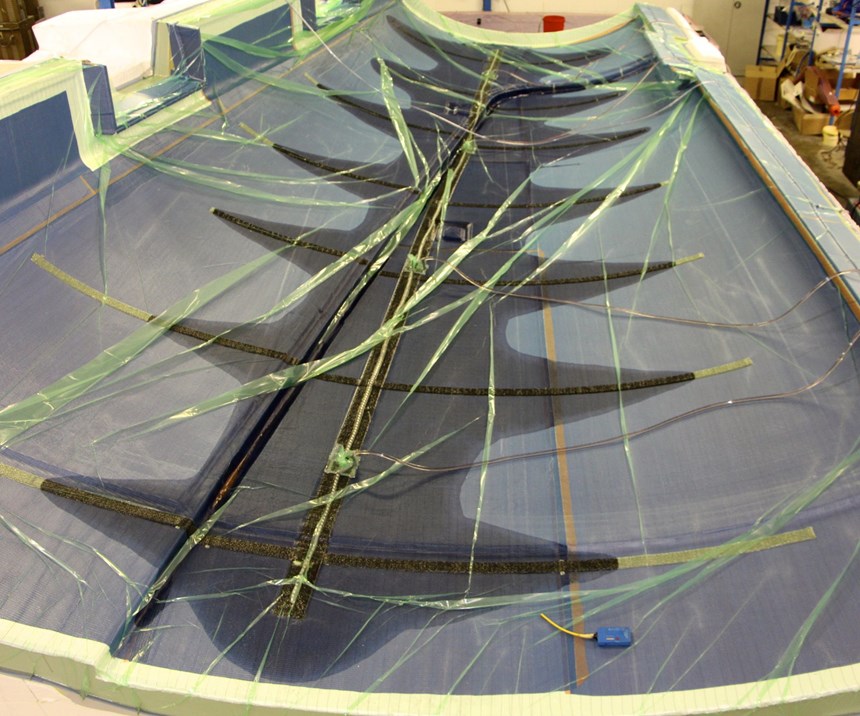

Fabrication of the composite parts then began (Step 2), using four plies of biaxial stitched glass fiber fabrics and VE100T vinyl ester resin, both supplied by MC Technics (Visé, Belgium). “We cut and laid in the fabrics,” says Vaandrager, “using spray adhesive where needed to hold the dry laminate stack onto vertical sides and into corners.” Both masts used CORECELL M structural foam core from Gurit (Newport, Isle of Wight, UK), which was perforated to help with resin flow during infusion. “For the glass fiber/vinyl ester mast, we used our typical one-shot infusion method on the skin-core-skin dry stacks.” He notes that infusion took just 2-3 hours for each leg and platform (Step 3).

“For the carbon fiber mast, we used a different technique because of the difficulty in getting good resin flow in the much thinner, tightly packed layers,” Vaandrager explains. Laminates comprised two plies of woven and stitched biaxial carbon fiber fabric and Sika Axson Bi-resin CR83 infusion epoxy supplied by Fatol-Kunststoffen BV (Hengelo, The Netherlands). “We first laid the outer skin and infused it. We then bonded in the core with epoxy adhesive and vacuum bagged it to the outer skin. We then laid the inner skin and infused that final layer. So this technique was much more labor-intensive, requiring at least twice the time of the glass fiber mast.” He notes the canopy was produced using the same three-step process and infused in 4-6 hours.

All of the parts for the carbon fiber mast had to be post-cured to attain full epoxy structural properties; also, some parts would be painted a dark color and thus needed the higher heat deflection temperature that a post-cure provides. The carbon fiber/epoxy laminates were cured in 6 hours at 70°C and post-cured in 2-3 hours at 90-100°C. This was achieved in Vabo Composites’ 8-by-5m oven for smaller parts, but for the large legs a 10-by-20-by-5m tent was used as a temporary oven with a large diesel heater. “We thermocoupled the parts and used a digital controller to ensure that we achieved the correct cure cycle, which also provided a record for Lloyd’s,” says Vaandrager.

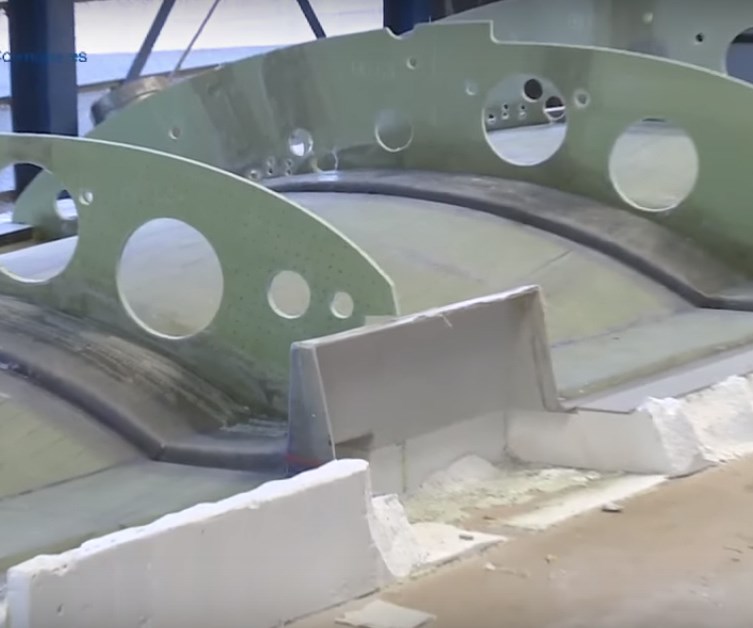

Infused parts were demolded (Step 4) and stiffening ribs were fabricated for the uprights/legs of both masts and for the carbon fiber mast’s canopy. Made from the same basic glass fiber and carbon fiber foam-cored laminates as the parts they would reinforce, the ribs were cut from large flat infused panels (Step 5). Holes for the exhaust pipes and cable chases that would be encased within each mast were also CNC machined from each rib. “We hand sand the composite laminate to prepare the bonding surfaces for the ribs and also when we bond mounting plates for equipment and small inserts for hardware,” says Vaandrager. The stiffening ribs were then bonded roughly 1m apart in the mast legs and carbon fiber canopy (Step 6).

Assembly and installation

With all parts fabricated, each mast project could move forward to the next stage — assembly. “For the glass fiber mast, we transported the two large legs, four platforms and all other parts to a covered shed next to where that yacht was being constructed,” Vaandrager relates (Step 7). “We built scaffolding to support and locate the platforms for attaching to the legs. Meanwhile, we prepared the legs, inserting the exhaust pipes and cable chases.” (Step 8)

Vabo Composites used a crane to lift each completed leg onto a fixture mounted on steel rails in the floor (Step 9). “We then slid each leg on its fixture into the scaffolding to mate with the platforms,” Vaandrager recalls. Note that each leg had been built with small cutouts to receive the platforms. “So there was only one way the legs and platforms could fit together,” he adds.

“This mast was designed to adhesively bond together, but we were not sure if assembly would occur in the summer or winter, and the shed was covered but not temperature controlled,” says Vaandrager. “So we chose to adhesively bond and bolt the legs and platforms together. However, we could have used adhesive only. The mechanical fastening just helped to alleviate any temperature-induced tolerance issues.” The bolts also held the parts together while the Gurit adhesive cured.

The same adhesive was used to bond the carbon fiber/epoxy mast, but parts were clamped together, not mechanically fastened. “Also for this mast, every bondline was taped [with epoxy-impregnated woven carbon fabric] because we were pushing the structure so far to the edge [for lightweight], we needed every layer,” Vaandrager explains. For the glass fiber/vinyl ester mast, some of the ribs were taped and all of the major structure joins were taped after the legs and platforms were bonded and bolted. He notes a workmanship detail during this process: Where the outer join lines are taped, there are recesses designed into the parts so that once taped, the whole surface is flush and smooth for a high-quality cosmetic finish after painting.

At this point, each mast is ready for installation on its yacht. “One single part is lifted and placed onto the yacht,” says Vaandrager, “complete with pipe chases inside and everything prepared for installation of the cables and electronics equipment, exhaust system, etc. This is what we promise and sell.” The yachtbuilder/refitter — Vabo Composites works with some of the most renowned companies in the industry — actually secures and installs the mast onto the yacht (Step 10). “They use a crane and first prefit it to the vessel,” he explains. “They will then move the mast back off the yacht and prepare the mast for paint and systems installation. They install the cables, exhaust, etc., and then apply final paint, after which they place the mast once with the crane and complete the final installation onto the yacht. We support them throughout this process as needed.”

Future growth, need for change

What is the largest challenge in these projects? “Managing the complete process and myriad details,” says Vaandrager. There are so many simultaneous processes occurring during yacht construction — exterior design, interiors, electronics, propulsion and steering — sometimes changes are made to solve emerging problems without understanding the huge impact they could have on the fit and installation of the composite mast.

Composites, however, offer a multitude of benefits in this application. “We do see that these large structures will continue for us,” Vaandrager asserts. “The yachtbuilders try to solve weight and performance issues with aluminum for as long as they can, but in the end, they see they must go to composites. Vessels continue to be larger and taller, which causes weight and center of gravity issues.” The reduction of weight high up on the yacht lowers the vessel’s center of gravity, improving its stability in the water. The composite structure also saves on maintenance costs, eliminating the need for repainting due to its excellent corrosion resistance in saltwater. “We have more requests now than in the past,” notes Vaandrager. “And I think that builders will increasingly start the vessel designs with these types of structures in composites from the project beginning, instead of switching from aluminum later on, to save time and cost.”

What materials and process needs does he see for future marine composites construction? “If you could make your own molds using robots and then they could also cut pieces like ribs, then the price of construction will go down 20-30%,” Vaandrager replies. “If you could do more in an automated way to drop labor hours. We began working with a robot this year for our ACEDOO composite doors for ships. Here, we have a simple goal: build a door without man-hours. The only problem we had was with interfaces in the software between programs. But these robots are cheaper and much more flexible than large CNC systems.”

He also points out what is possible now in composites with thermoplastics. “Airborne is a Dutch company and we see what they are doing,” Vaandrager explains (read “Airborne, Siemens and SABIC partner to mass produce thermoplastic composites”). “In automotive, they are building composite parts in 3 minutes in order to make them affordable. So we see this is possible. It is just a matter of adapting the technology in a way that makes sense for boatbuilding budgets and structures.”

Another issue with these large structures is molds. “We have more kg in molds than we do in our products for project like the masts,” he observes. “This construction method is not sustainable. We invest hundreds of thousands of euros for the molds and then must pay to scrap them. We need a new solution. If we could build molds out of recyclable thermoplastic or sheet foam, then that would be better for the environment and cheaper.” He notes the development of 3D printing for boat and yacht molds, and believes this also may be promising. “But if we started, not with a mold, but with beams and then cover the beams with a skin, this is another way of thinking,” says Vaandrager. “Now, with digital technologies, it may be possible to use this method and still achieve accurately shaped and dimensioned structures, but there are still many solutions needed for such an approach.”

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More