The list of mechanical functions that composite materials are expected to provide is well known and long: Strength, stiffness, toughness, durability, weatherability, corrosion resistance, impact resistance, fire resistance. This last requirement is one that composites have been addressing for many years. However, the industry is seeing an uptick in demand for fire performance, driven by the development of electric vehicles (EVs) — both on the ground and in the air — and increased penetration, finally, into the fire-conscious rail, marine and construction markets.

Material suppliers, as will be revealed here, are responding to that market pull, but the industry cannot rely only on traditional fire-resistance solutions to meet the demands of this market. For example, furan and phenolic resins have long been solutions for fire-resistant composites. They are, however, crosslinked via condensation reactions, which makes processing more difficult, often creating porosity that requires multiple operations to achieve a good surface finish. They also tend to be brittle. Meanwhile, fire retardants such as aluminum trihydroxide (ATH), added to resins to provide fire resistance, typically require a loading of 20% by volume, which can adversely affect processing, mechanical properties and surface finish. Meanwhile, halogenated flame retardants, once an attractive alternative, are now banned by pan-European regulations including REACH and RoHS. Thus, the composites industry continues to research and develop new solutions.

Fire-resistant materials must also provide sufficient time and protection for occupants to escape in case of fire. In the most stringent applications, this means not only preventing the spread of flames, the release of heat, the transmission of temperature and the formation of toxic smoke, but also maintaining load-carrying capability in the composite material for as long as 60 minutes.

FR methods and measures

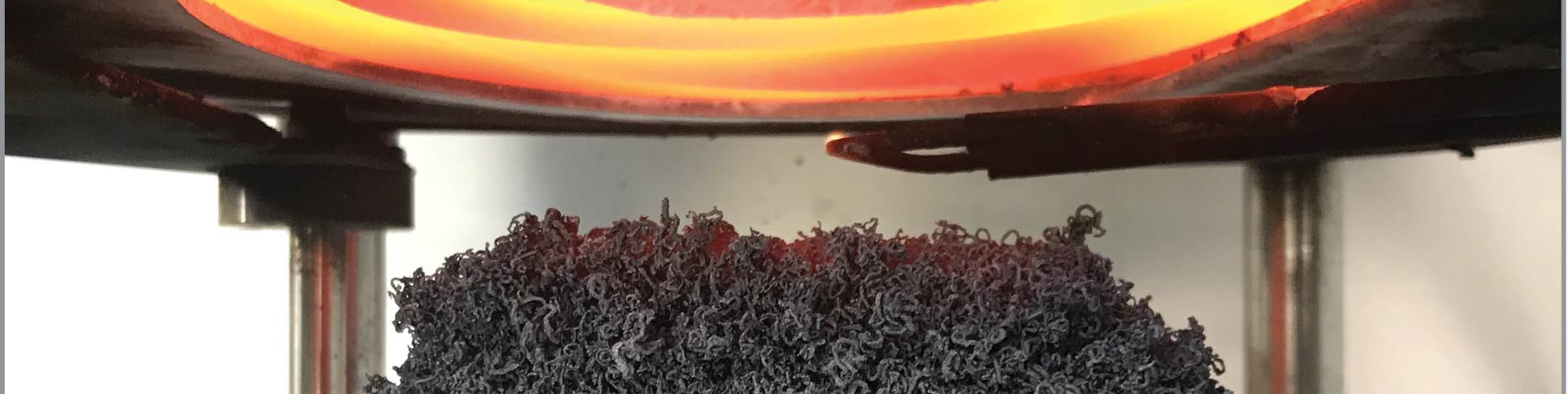

Generally, inorganic fibers (e.g., glass, carbon, basalt, ceramic) and inorganic matrix materials (e.g., ceramic/carbon, metals, polysialate/geopolymers) do not burn, and many can withstand high temperatures. However, most organic fibers and polymer matrices will decompose when exposed to high temperatures and fire (Fig. 1) and may also release flammable gases and toxic smoke. KEVLAR para-aramid and NOMEX meta-aramid organic fibers are notable exceptions, being organic fibers with inherently flame-resistant chemical structures.

A composite’s fire performance is measured by a variety of characteristics, including ignition, ability to self-extinguish, flame spread, burn-through, heat release, smoke generation and smoke toxicity. Another frequently cited requirement is limiting oxygen index (LOI), which measures the minimum oxygen concentration (in percent volume) necessary for combustion; thus, higher LOI means higher flame resistance. The standard tests for these performance measurements vary by industry and range in test sample size from small coupons to full-scale constructions representative of in-service use. More details are provided in the online sidebar “Measuring and improving fire resistance in composites”.

There are two main approaches for improving fire performance in composites: Increase the flame resistance of the matrix and/or reinforcing fibers, or provide a protective coating.

Fibers can be treated with flame retardants (FR) such as borax/boric acid mixtures and ammonium salts of strong acids. Flame retardance in matrix resins can be improved by three basic methods: incorporating an FR compound into the polymeric backbone; mixing FR compounds, particulates and/or nanomaterials into the resin; or adding an intumescent to the matrix. Intumescents are substances that are activated by heat to expand and form a porous, carbonaceous char that thermally insulates the underlying composite and inhibits production of flammable volatiles. Coatings may use FR additives or intumescents.

FR additives may exploit multiple mechanisms to slow composite decomposition, heat release and flame spread. For example, additives may decompose via an endothermic reaction, cooling the composite. This decomposition may also produce water and noncombustible gases that dilute the concentration of flammable gases. Additives may also char and/or produce a gaseous layer that excludes oxygen and suffocates the fire. Often, two or more FR agents are combined synergistically to increase and broaden a composite’s fire performance — for example, one FR compound may reduce heat release, while the next reduces smoke and the third produces char.

FR options for infusion

A systems approach is exactly what materials supplier SAERTEX (Saerbeck, Germany) has pursued with its LEO series of FR products, which include the company’s noncrimp fabric (NCF) reinforcements as well as FR foam cores and ATH-filled or intumescent coatings. The series’ first product, LEO SYSTEM, which was launched in 2013, combines FR-treated SAERTEX fabrics with FR resins and FR or intumescent gelcoats. “We wanted to close the gap between fire performance and mechanical performance,” explains Jörg Bünker, SAERTEX head of R&D/application service for LEO. “With LEO SYSTEM, it is possible to get high fiber content and high fire performance. We started with a modified fabric and vinyl ester infusion resin that does not use ATH or other fillers, but instead is treated with liquid fire retardants. It also avoids all halogens and bromides, so no toxic materials, which means no toxic smoke or fumes.”

The SAERTEX LEO SYSTEM is being used in the floors of 66 ICE Version 3 high-speed trains in Germany, cutting weight by 50% versus previous plywood panels (Fig. 2). The composite panels average 2.4 by 1.2m in size and comprise SAERfoam core, glass fiber NCF skins, LEO infusion vinyl ester resin and a LEO protection layer in the finish. Using vacuum infusion with reusable silicone membranes from Alan Harper Composites (Cornwall, UK), the floor panels are made by SMT Montagetechnik (Forst, Germany), the exclusive supplier to Deutsche Bahn, producing 25,000 m2 of panels for the 66 eight-carriage trains.

Bünker says LEO SYSTEM has been well-received, “but some customers wanted to use epoxy, polyester or thermoplastic resins, so we developed LEO COATED FABRIC.” SAERTEX applies the intumescent coating after fabric manufacture. “It impregnates the fibers a bit, enabling a good connection to the composite,” he explains. “It cannot wear or scrape off like some paints. In a fire situation, the intumescent coating creates a foam, insulating the composite from flame and thermal energy. It provides fire resistance for load-bearing structures without smoke or toxic fumes, meeting the highest requirements.” LEO COATED FABRIC is supplied in rolls and used like any other infusion fabric. “The only thing to watch,” Bünker cautions, “is if you use it as a top layer immediately before the vacuum bag, because you cannot impregnate through this layer to any laminate layers underneath.”

The third product, SAERcore LEO, “is a micro sandwich material comprising chopped strand mat (glass fiber) on both sides of a specially FR-modified polypropylene (PP) core,” says Bünker. “This material combination is easy to drape and provides good resin flow during infusion.” SAERcore LEO is placed into a molding tool with a countermold in a light resin transfer molding (light RTM) process. “You can adjust the part thickness via the cavity between the mold and countermold,” he notes, “and can calculate how much resin content you want up front.” SAERcore LEO is available in a range of densities and thicknesses, and can be used with vinyl ester, epoxy and polyester resins. “You can add ATH to the resin if you want to combine FR methods,” says Bünker. “The material has been used most often with polyester RTM applications. We have suggested using a filled resin and gelcoat from Scott Bader, as it has been tested and works well.”

All three SAERTEX LEO products have passed the European rail applications standard EN 45545, including the most stringent HL3 class for underground and high-speed trains. SAERcore LEO is being used by global rail products supplier BARAT Group (Saint Aignan, France) to produce access doors for Stadler’s (Bussnang, Switzerland) SMILE high-speed trains. The doors feature complex molded areas, made in a single piece using RTM with FR resins.

SAERTEX LEO products have also passed ASTM E84 for building applications, and were used by Carbures Civil Works Spain (Puerto de Santa Maria, Cadiz) to infuse cored panels for the lightweight roof of the Pavilion of Inspirations in the Norman Foster Foundation headquarters (Madrid, Spain). “This type of application is also a good fit for SAERTEX COATED FABRIC because they typically use large, flat panels with insulation requirements similar to marine bulkheads, for example, mandating a certain temperature profile after 30 and 60 minutes of exposure to fire,” Bünker says.

Intumescent veils

Another fire-resistant solution for use in composites is intumescent veils. Tecnofire is a family of intumescent nonwoven products made by Technical Fibre Products (TFP, Burneside Mills, UK and Schenectady, NY, US) using a wet-lay process (Fig. 1). Made in roll form, the products range from 0.4-10 mm in thickness (0.5-2.0 mm is the most common). Its maximum width is 50 inches and it can be slit into tapes as narrow as 0.25 inch wide. Tecnofire can be used with pultrusion, RTM and vacuum infusion processes with a range of resins including epoxy, vinyl ester, unsaturated polyester, thermoplastics and FR-modified systems from Ashland (Columbus, OH, US) and Polynt (Carpentersville, IL, US).

“When Tecnofire materials reach 190°C, they activate and expand unidirectionally in the z-direction up to 35 times their original thickness,” explains TFP business development associate Scott Klopfer. “That expansion, which is irreversible, forms an insulative char layer. Tecnofire is typically used at a part’s surface, where it would be exposed to heat and flame during a fire.” Tecnofire has been specially designed to be stable during a fire and protect underlying structures.

“We have a lot of freedom in what we can put into this material, including different types of fibers and particles,” Klopfer explains. “We tailor the composition for each application. For example, we can add ATH as a powder during the Tecnofire manufacturing process and disperse it evenly throughout the material.” He contrasts this with the traditional process of adding ATH to the matrix resin, which can cause increased viscosity. “The ATH can also migrate or filter unevenly during the molding process,” says Klopfer. “Tecnofire avoids these problems.”

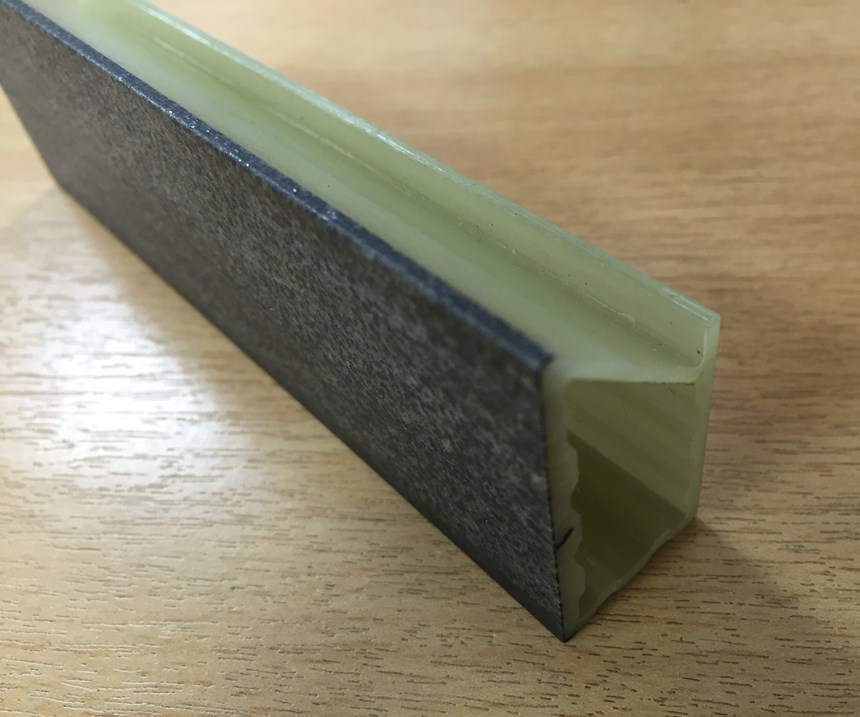

TFP has created more than 100 versions since Tecnofire’s inception in 2005, with 10-15 grades commercially in use. One has epoxy resin already infused into it, available in 4-by-8-ft sheets, like plywood. “This was created for an industry where they needed a veneer type of material,” he explains. “It is one of the highest expanders. We also have a patented version that is electrically activated using metal-coated fibers for a conductive, fire-resistant composite. But no matter what the grade, Tecnofire becomes an integral part of the composite.”

Applications include continuous profiles with built-in fire protection for use in roof systems, window and door frames, steel beam coverings and modular composite housing kits. “It is also used for 45- and 90-minute rated doors, providing a solution to pass the UL 10C Positive Pressure Tests of Door Assemblies,” says Klopfer. “This standard ensures that doors remain intact to prevent spread of flame and hot gases between rooms. At the end of the test, the door has to withstand a high-pressure water fire hose and still have integrity to stay in place.”

See “Tecnofire adds fire resistance to transportation and infrastructure applications” for more applications of Tecnofire.

Bio-based FR prepregs

Polyfurfuryl alcohol (PFA) is a thermoset resin that meets phenolic performance with better surface processing and sustainability. Its manufacture begins with hemicellulose derived from biomass — corn cobs, rice and oat hulls or sugar cane waste (bagasse) — which is converted to the furan-based furfuryl alcohol and then polymerized (via acid catalysts or temperature) into PFA. “Glass/phenolic has been the go-to material for such a long time, but if you want to accelerate weight reduction, you look at carbon fiber and PFA,” says Gareth Davies, commercial manager at prepreg supplier Composites Evolution (Chesterfield, UK). Its Evopreg PFC prepregs combine PFA resin and reinforcements such as flax, glass, aramid, basalt or carbon fiber, and have passed FAR 25.583 flame, smoke and toxicity (FST) tests for aircraft interiors as well as EN 45545 class HL3 for rail.

Another company offering PFA prepregs is SHD Composites (Sleaford, Lincolnshire, UK). The company was founded in 2010 by Steve Doughty, a 20-year process development engineer with Advanced Composites Group. SHD Composites has grown significantly, adding factories in Slovenia and Mooresville, NC, US. It offers two PFA-based phenolic resin products: FR308 and PS200.

Developed as a phenolic replacement for aircraft interiors, FR308 passes all aircraft FST requirements as well as EN 45545 HL3 for rail. PS200, which meets fire protection requirements for aircraft batteries mandated by the European Aviation Safety Agency (EASA), is already in use at manufacturers of general aviation aircraft. In a lab test recreating thermal runaway conditions for lithium-ion batteries, a prototype battery box made using PS200 proved its performance. “Though the inside temperature reached 1,100°C, the outside never exceeded 250°C and the box never burned or decomposed,” says SHD Composites technical director Nick Smith. The company is now working with several electric vehicle engineering companies on battery boxes for cars and other types of vehicles.

Both PS200 and FR308 are formulated to handle like an epoxy, typically curing at 120-130°C in one hour. Both also pass BS 476, the British material specification for building interiors, which Smith sees as a sizable emerging market.

Smith highlights rail as another market for PFA materials that is developing rapidly. “We are bidding on quite large projects,” he adds. Davies agrees, citing several exhibits at the 2018 InnoTrans International Trade Fair for Transport Technology in Berlin, including the CETROVO metro train by the world’s largest rolling stock manufacturer, China Railway Rolling Stock Corp. (CRRC, Beijing), which features a carbon fiber composite car body, bogie frame and driver’s cab equipment cabinets. Meanwhile, Composites Evolution has worked with composite structures manufacturer Bercella (Varano de Melegari, Italy) to develop a lightweight composite support for rail seats (Fig. 3). “It is quite a chunky, heavy part in metal,” says Davies. The 1m-long part made from carbon fiber Evopreg, however, weighs less than 5 kg. “Multiply the weight savings by the number of seat supports per rail car, and the composite redesign reduces the axle load substantially.”

Bio-based PFA prepreg is also featured in a carbon fiber reinforced plastic (CFRP) sandwich panel door leaf developed by TRB Lightweight Structures (Huntingdon, UK). Compared to bonded aluminum door leaves, this sustainable CFRP alternative, featuring a 100% recycled foam core, cuts weight by 35% — from 40 to 26 kg — at a comparable part cost. TRB’s lightweight door leaf meets EN 45545 HL3 with an expected 40-year service life, offering superior fatigue resistance and lower maintenance costs vs. aluminum, as well as a lighter-duty door operating system for further weight and energy benefits.

Though both Composites Evolution and SHD Composites also offer FR epoxies, Davies says that in terms of test data, “they cannot provide the full FST performance provided by PFA-based resins, and they are more expensive.” Smith notes that FR epoxies still have higher toughness, “but PFA resins have better toughness than phenolics, and we are working on formulations to further improve that. Also, the fire retardants in FST epoxies slow down the effects of fire, but they will still burn and give off toxic fumes. When PFA burns it’s only releasing CO2 — no toxic gas is produced.”

PFAs also can outperform traditional phenolics in surface finish. “This is a big issue in aircraft interiors,” he explains. “Manufacturers want better part quality the first time without the need for rework. Historically, FR composites have been harder to process, requiring multiple rounds of surface prep due to porosity. PFA systems offer an improved surface finish with increased glossiness. This is confirmed by the Horizon 2020 project IntAir, which showed that directly substituting PFA prepreg for phenolic reduced molding cycle time by 34%, manual finishing by 70% and cost of final interior components by 58%.

Eliminating organic materials

There are also new composite technologies that achieve fire resistance by foregoing organic materials completely, relying solely on inorganic fibers and polymers. Traditionally, inorganic polymers have tended to be expensive and/or difficult to process. Some are also brittle and/or sensitive to notching and impact damage. However, polysiloxane, polysilane and polysialate/geopolymer can be blended into a resin or synthesized into the backbone of organic polymers, as can the base inorganic monomers. This approach has been used successfully in FR development work with polypropylene, polyethylene, epoxy, polyvinyl, polyester, polyamide and polyurethane resins. Geopolymers, especially, seem to offer potential in current research.

CFP Composites (Solihull, UK) combines chopped carbon fibers and inorganic resin to produce what it calls FR.10, which has passed seven-hour fire resistance tests at 1,500°C while emitting almost no smoke or gas (Fig. 4). The materials offer a cost-effective, structural alternative to metal that is lightweight — 2-mm-thick FR.10 weighs less than 3 kg/m2 and 5-mm-thick is less than 6 kg/m2. FR.10 has also passed structural tests under load, withstanding direct flame at 1,200°C for two hours, with no burn-through while providing enough thermal insulation to place a bare hand in full contact on the back side. It is available in 1.3 by 0.8m sheets in thicknesses up to 20 mm and can be easily joined or bonded using conventional fasteners or adhesives.

The process used to make FR.10 combines the chopped fiber and inorganic resin in a water-filled mix. This mix is then released, producing fully resin-infused flat and net-shaped preforms with x-, y- and z-direction fiber structure in seconds. These are then transferred to a 1,000-MT press and compression molded to form flat sheets or shaped parts. “We can produce lightweight parts very quickly, with no waste,” says CFP Composites managing director Simon Price. Patented globally, this process enables lower cost versus conventional composites, while the inorganic composition delivers higher fire performance. “The two key hurdles for composites adoption in building/construction, heavy ships and oil and gas are cost and fire regulations,” says Price. “We are opening new applications for composites, replacing metals or ceramics.”

Another new solution is fi:resist for pultruded non-flammable profiles. It was developed by FISCO GmbH (Zusmarshausen, Germany), a joint venture founded in 2015 between German fastening specialist Fischer (Waldachtal) and in-vehicle equipment producer Sortimo (Zusmarshausen). At the 2018 European network for lightweight applications at sea (E-LASS) Seminar Day (June 26, Pornichet, France), Fisco product manager David Thull described fi:resist as using 100% inorganic materials that produce no fumes when exposed to flame. In addition, the matrix and glass fibers reportedly maintain their strength up to 1,000°C and 600°C, respectively. The material also provides high thermal insulation and reportedly meets DIN 4102-1 and EN 13501-1 requirements for the most stringent Class A1 construction materials.

Thull describes using fi:resist for fire-resistant cable ducts, enabling larger spans with fewer supports thanks to the material’s high structural performance. Other suggested applications include partition walls on ships, decking and rails for ship balconies and fireproof roller doors. He says future applications could expand to the automotive and aerospace industries. Fi:resist was recognized with a 2016 JEC Innovation Award in the construction and infrastructure category.

Continued development

Nanoclays are another area of significant development, showing potential for high FR performance at low cost. They promote formation of char, and because of their very small particulate size and ability to disperse at a sub-micron scale, smaller amounts of nanoclays are needed compared to macro-scale additives. When uniformly dispersed in a resin system, nanoclay amounts of 5-10% by weight can reduce peak heat release by 70%. Initial work on graphene nanoplatelets (GNPs) and carbon nanotubes (CNTs) have also shown positive results.

While EU-funded development programs such as MAT4RAIL and FIBRESHIP pursue significant milestones in new FR materials and improved composite performance, there are numerous other high-potential initiatives. For example:

- US Navy program to replace PMR-15 with a sustainable resveratrol-based phthalonitrile resin;

- Hybrid polymer/inorganic foams developed in India that, without FR additives, are self-extinguishing, do not drip or collapse from flame and show a 75% lower peak heat release rate than commercially available fire-retardant polyurethanes made using ice scaffolding and water as the solvent/porogen;

- MAI Sandwich aircraft interiors comprising foam core and CFRP laminates, all made using Ultrason E polyethersulfone from BASF (Ludwigshafen, Germany), processed into 1-3m2 panels in less than 5 minutes via automated thermoforming and overmolding for FST-compliant sidewalls, baggage bins, doors and galley components.

(Further details in online sidebar, “Measuring and improving fire resistance in composites”)

“Our goal is that by providing a variety of high-performing materials, fire retardance becomes not the main issue for the customer, who instead can focus on meeting the needs of the project overall,” says Bünker at SAERTEX. Indeed, the composites industry as a whole is well on its way to that end.

References

“Flame Retardant Polymer Composites” by Mahadev Bar, R. Alagirusamy and Apurba Das, Department of Textile Technology, Indian Institute of Technology Delhi, New Delhi, India. Fibers and Polymers 2015, Vol.16, No.4, pp. 705-717.

“TR 18001 – A literature review of natural fibre composite fire properties” by Asanka Basnayake, Juan Hidalgo, Luigi Vandi and Michael Heitzmann, UQ Composites Group, University of Queensland, Australia. April 2018.

“Composites and fire: developments and new trends in flame-retardant additives” by Belén Redondo, Composites Department of AIMPLAS, Plastics Technology Centre, Valencia, Spain.

CompositesWorld webinar “Enhancing Composite Fire Protection Using Advanced Nonwovens”, presented by TFP on Jan. 31, 2018.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More