Single bagging can do the job

Mechnical engineer Peter Schwarzel (CarbonWorks, Coombabah, Queensland, Australia) comments on the “Engineering Insights” article in the CT December 2010 issue, titled “Double-bag infusion: 70 percent fiber volume?”

I’d like to comment on the “Engineering Insights” article in the most recent issue of CT, titled “Double-bag infusion: 70 percent fiber volume?” (See “Editor's Picks," at upper right) I have been involved in vacuum infusion as an engineer for more than 12 years and, because there is no single source of accurate information on the subject, I have had to figure out how to control the many variables involved in this process. I’ve also had the opportunity to share what I’ve learned with others who use the infusion process.

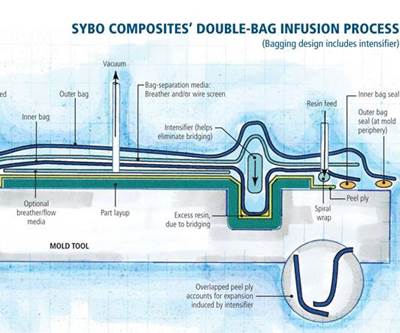

In the article, Russel Emanis credits his double-bag process with improving the consolidation of the part due to increased pressure, but because we only have 1 bar/14.7 psi at sea level to compress our part, it doesn’t matter whether we have one or two bags, the minimum thickness achievable is the same. The Emanis process uses two steps: 1) an inner bag at low vacuum pressure to fill the part and then 2) the outer bag and full atmospheric pressure to consolidate and bleed the part. This is similar to the way prepregs are processed.

All of the issues raised in the double-bagging article can be addressed with a single bag if the correct procedure is used. The main reason the double-bag method works is that it improves the total vacuum integrity of the job. It is difficult to explain why in the space I have here, but the same result can be achieved by using a single bag that is double-taped at the bag edges, or by using double-stage vacuum pumps, or by using an improved vacuum scavenging layout for the job.

Using carbon fiber, a fabricator should achieve a fiber content by weight (Wf) of 70 percent (a fiber content by volume, or Vf, of 60 percent) every time. The Wf = 70 percent equation comes from the fact that this is the thickness the laminate achieves if compressed under 1 bar/14.7 psi of pressure. If you put a laminate into a mechanical press under the same pressure, you will achieve the same thickness. The aim of a good infusion is to maintain a constant part or bag volume as the filling proceeds. The stack has a natural elasticity that, if permitted to so do, will expand the bag, so vacuum integrity is paramount in keeping the bag at a constant volume.

If the part or bag volume increases, it could mean that the pressure differential has been reduced. Some fabricators vary the pressure as the job progresses. This is generally a poor strategy because a change in vacuum pressure will create a change in part or bag volume. The increase in part/bag volume also could be the result of outgassing or a leak of some sort. The tricky aspect of infusion is that it is done with a flexible membrane that is very sensitive to bag volume changes. In Light RTM or VARTM, processes that use rigid molds, this problem is minimized.

There are four basic problems encountered in infusion. The most common infusion problem is poor vacuum integrity. The use of an absolute vacuum gauge quickly identifies this problem. (The use of in-bag and off-job analog gauges is not good enough until the fabricator is thoroughly experienced with the process and consumables.) Why is the vacuum integrity poor? For one thing, we have found several “good” brands of vacuum bag are microporous. For that reason, there is no way you can get the bag down to the correct pressure. But you can do so if you use two microporous bags, because if the outer bag leaks, the leak goes to the pump not to the job. This is one possible reason for the double-bag method’s improvement but the problem can be avoided easily by using a non-leaking single bag.

A second problem is styrene outgassing, which can happen under very good vacuum and often is mistaken for leakage. But if the process layout is thought out well, the outgassing only occurs at the resin front (a free surface, if you want the technical reason) so the gasified styrene is drawn out by the pump and doesn’t remain under the bag. There are common resin-fill strategies that are focused on filling fast but, usually, also capture outgassed styrene in the job. Grooved foam, often used as a flow medium, also captures outgassed styrene due to its very fast fill and crossed grooves. When filling is done more slowly, the outgassed styrene is taken away from the resin front and very high-quality laminates are produced. There seems to be a big variation in potential outgassing from different resin suppliers. I suspect that there are other solvents in some resins that outgas because I haven’t had this problem with good-quality styrenated resins or epoxy resins.

Another issue is saturated gasses. There is a lot of dissolved oxygen and nitrogen in resins. Plus when we mix resins, we introduce quite a bit of air as well. For small amounts of resin, degassing is a practical solution to this problem. But for large quantities of resin, degassing is unrealistic. Various authors have estimated that from 3 to 10 percent by volume of resin “as delivered” is saturated gasses. Because infusion is a vacuum process, this gas has the potential to expand and foam into our job. Under vacuum, the saturated gas volume increases dramatically and can influence the bag volume. However the resin in an infusion job is closer to atmospheric pressure than to vacuum. Remember that the resin is connected to the atmosphere in the bucket, not to the vacuum pump. So this higher pressure means that the true saturated gasses are unlikely to come out of the resin during an infusion so the mixed air is probably the culprit.

Similarly, water in the reinforcement stack can cause problems. When 1 liter of water vaporizes, it becomes about 1,000 liters of vapor at 1 bar/14.7 psi vacuum. This is definitely a “big bag decompressor baddy.” It really makes a difference to keep vacuum on the dry stack for some time prior to filling if you want a perfect result. Vacuum “soak” time lets the water flash off and get to the pump and out of the job.

The use of an intensifier, as shown in the double-bagging article, runs the risk of losing pressure on the side walls because there is little pressure applied to the laminate in the through-thickness direction. Any good laminator can tell you that if you have a bag or laminate bridge, the bag “pull down” will not correct it. The bridge must be fixed before the bag is pulled down.

At one point, the double-bag story describes a situation in which, after the resin front has moved past, the laminate gets thicker. This points to a lack of vacuum integrity in the system. It’s true that the pressure difference in this area is reduced, but in a vacuum bag system that has been built correctly, the laminate actually gets thinner as the resin goes past because the fibers are lubricated and the stack can compress a little bit more.

Double bagging is easy to do on small parts but is difficult to do on big parts, such as 15m/49-ft catamarans — especially when you need to place resin and vacuum ports through two bags and a breather. As the job gets bigger, the vacuum system needs to be understood better to maintain the same level of quality in the laminate as you get when bagging a small part.

In short, there is a considerable amount of infusion information available — some of it accurate and some not. Infusion is a great process and there is always room for improvement!

Related Content

AMRC Training Centre introduces composites apprenticeship opportunity

With partners McLaren and Teledyne CML Composites, the Training Center will train new composites technicians in South Yorkshire to build up the future industry workforce.

Read MoreBelzona opens fifth European SuperWrap Training Centre

Global training facilities provide intensive, first-class installer and supervisor training for proper use and application of Belzona composite pipe and tank repair systems.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreThe Native Lab launches composites course training membership plan

Courses that touch on the fundamentals of composite materials, design, analysis and more are available for individuals and companies alike through TNL’s online platform.

Read MoreRead Next

Double-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)