Double-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

Share

Engineering Challenge:

Develop a method for vacuum infusing a laminate that increases its strength but reduces its weight by simultaneously reducing the laminate’s void content and increasing its fiber volume beyond that possible with conventional vacuum-bagging regimes.

Design Solution:

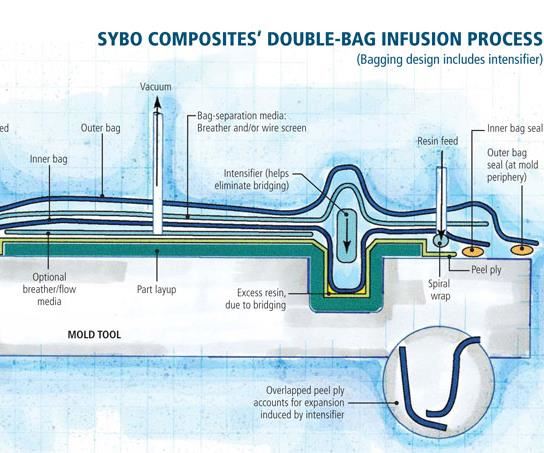

The double-bag infusion technique, which splits the two main vacuum functions, assigning volatiles extraction (removal of entrapped air, ambient moisture and/or solvents) to the inner bag and then using the outer bag for compaction.

Double vacuum bagging was first used in the 1980s to reduce porosity and increase mechanical properties in prepreg and wet-layup composite repairs. More recently, NASA and The Boeing Co. (Seattle, Wash.) applied its basic principles to vaccum-assisted resin transfer molding (VARTM) and infusion, achieving aerospace-quality composites out of the autoclave. Unaware of the NASA and Boeing efforts, Russell Emanis tried double bagging with resin infusion more than 15 years ago. Excited by the results, this former composite process manager on Lockheed Martin Aeronautics’ (Forth Worth, Texas) F-22 program and now district sales manager for JB Martin (St. Jean Sur Richelieu, Quebec, Canada), developed his own process and subsequently recommended it to a variety of companies, including SYBO Composites (St. Augustine, Fla.) and Air Command International (Caddo Mills, Texas). Each reports that the process has achieved lighter but stronger parts.

Double bagging defined

The basic technique is to apply two discrete vacuum bags, an inner bag, next to the laminate, and an outer bag, which is sealed to the tool outside of the sealed inner bag perimeter. From there, however, the technique’s details and explanations of why it works differ with almost everyone who uses it. The most successful applications use what Emanis calls a venting layer to separate the inner and outer vacuum bags.

“Otherwise,” he explains, “they will suck down together and act as one bag.” But the means to do so range from a solid tool (caul plate) to flexible material (breather cloth, flow media or noncrimp fabric). Practitioners also differ about when and how much vacuum to apply to each bag, but Emanis believes it is essential to split the two main vacuum functions, assigning volatiles extraction (removal of entrapped air, ambient moisture and/or solvents) to the inner bag and then using the outer bag for compaction. All who use the process agree it improves volatiles extraction and compaction, and they report lower void content and higher fiber volume.

Grass roots double-bag infusion

Emanis’ double-bag technique was developed while he worked to mitigate infusion’s high labor cost at Lockheed Martin. Emanis first took infusion in this direction when he tried to help his wife’s company make small composite dishes for satellite TV applications. “We were pursuing an RTM Light type of process that was tight enough to give us the stiffness and cost we needed,” Emanis explains. He tried placing dissolving resin bags — small polystyrene film bags filled with resin — into deep draw corners with bagging film on top, to act as pressure concentrators. Once the resin was fed in during infusion, the bags would dissolve and the extra resin was there to wet out the problem areas, but Emanis still could not generate enough consolidation. A second bag enabled him to apply the pressure he had been seeking and squeeze resin out from the laminate under the inner vacuum bag.

Emanis’ process is unique, however, in that he applies two discrete vacuum pressures: The inner bag pressure is set for the optimum resin flow, given the materials and infusion setup. Vacuum pressure in the outer bag is defined to achieve desired fiber volume and is applied only after the laminate is completely infused. At this point, the resin feed valve is closed and Emanis opens a valve installed in front of the resin feed shutoff, giving the resin two out-flow paths (from the resin inlet and the vacuum inlet with catch pots) as the outer bag applies compaction pressure. Emanis says this setup consistently achieves close to 70 percent fiber volume (see additional reading on this subject under "Editor's Picks," at top right).

Lighter, stronger, cheaper

On a recent composite box structure for a military application, Doug Smith, founder and owner of Air Command International (ACI), says double-bag infusion enabled ACI “to beat our customer’s weight specification by almost 50 percent while still meeting strength and rigidity requirements.” ACI’s part weighs 6.4 lb/2.9 kg vs. the customer’s request for 11.6 lb/5.3kg. The box uses JB Martin 6-oz/yd2 (203 g/m2) carbon fiber 2x2 twill, 6-oz/yd2 3K carbon fiber plain weave, and 3oz/yd2 (102 g/m2) fabric made from Innegra fiber (Innegrity, Simpsonville, S.C.) on either side of a closed-cell foam core with flow media next to the Innegra on the tool-side skin. ACI infuses this sandwich with a newly developed 4505 toughened epoxy ambient-cure infusion resin from Endurance Technologies (St. Paul, Minn.). The box passed empty and weighted drop tests. In the latter, a 35 lb/16 kg weight was placed in the box and it was dropped 48 inches/1.2m. The box survived undamaged.

Smith comments that double-bag infusion enables a higher fiber-to-resin ratio. “We did a lot of our own testing in-house,” he explains, “to develop our own process method that works best for us.” Additionally, trial runs defined exactly how much resin is needed, and reduced the amount of resin used in production, avoiding wasteful overages.

Most of the parts ACI makes are small, under 4-ft by 8-ft (1.2m by 2.4m) in size, but the process also handles ultra lightweight 18-ft/5.5m hulls that SYBO Composites manufactures for Chittum Skiffs’ (Fort Lauderdale, Fla.) Islamorada flats boat. At one time, the hulls were infused with a single vacuum bag, but SYBO switched to double bagging, says CEO Dana Greenwood, because “the more weight we take out of the structure, the less draft the boat has, which enables it to go into shallower water and access fish others can’t.” SYBO started with a hull that weighed 320 lb/145 kg and dropped that to 280 lb/127 kg by optimizing core and other materials. “Double bagging enabled us to reach 260 lb /118kg without having to take materials out that we need for performance,” Greenwood claims.

SYBO notes one additional benefit. “For us, the ability to put an intensifier where the bag is not compacting the laminate sufficiently is key.” Intensifiers are silicone rubber inserts placed between the inner and outer vacuum bag in areas where resin tends to pool or where the bag tends to bridge (see drawing, at right). SYBO uses Big Blue L-100 vacuum bag film from Airtech (Huntington Beach, Calif.), which has more than 350 percent elongation and the extra toughness necessary in large infusion projects.

SYBO also uses Ashland’s (Columbus, Ohio) AME 6001 vinyl ester infusion resin as well as epoxy infusion resins from Endurance Technologies and engineered fabrics from JB Martin and Owens Corning Composite Materials (Toledo, Ohio). Greenwood cautions, “We stay under 19 in. Hg vacuum pressure … to avoid resin outgassing.” He has found that highly styrenated infusion resins tend to “boil” at around that pressure. “It looks like you have a leak in the bag,” says Greenwood, “but, of course, that’s not the problem at all.” Lower vacuum pressure during infusion reduces the propensity for problems. “Your goal with vacuum pressure in the inner bag is really only to pull resin through the laminate and achieve wet out,” says Emanis. “Using a second bag to achieve compaction reduces the risk for moving materials around and vaporizing your resin.”

Double bagging solves problems

A typical double-bag infusion for a 20-ft boat hull starts at the keel and flows outward, using vertical feed lines to achieve wet-out to the top edges. “Often you end up with a resin-rich laminate lower in the boat and a drier laminate as you move up the hull sides,” says Emanis. Similarly, there is a change from vacuum pressure to hydrostatic pressure on the fibers as the resin front moves forward. He illustrates, “If you take a flat piece of plate glass with fiber under vacuum on top of it, and you measure the thickness of the fiberglass before and after the resin flow front, you will see that it is thicker behind because there is no vacuum pressure left there to hold it down.”

Emanis asserts that even with full vacuum, the pressure difference in the bag could be 15 in. Hg over 4 ft/1.2m. In other words, the pressure in the bag drops even when the vacuum gauge at the pump reads 29 to 30 in. Hg. Emanis believes double bagging overcomes this because there are no effects from fluid dynamics in the outer bag; it acts purely to achieve compaction, pushing the inner bag down. The outer bag enables a positive pressure not possible in the inner bag and, Emanis contends, is also the cheapest insurance against a blown bag and laminate inconsistency.

Process control required

Emanis points out that those who use the process must be attentive to infusion process and environmental variables. Few processors, he observes, recognize that a change in barometric pressure can vary infusion results. The key is to identify the average barometric pressure for a given climate and geographic location, and account for it when specifying a part’s materials and process. Emanis explains, “If your part requires a 980 mbar [28.9 in. Hg] pressure to achieve the specified fiber volume, and you know the average pressure is 965 mbar [28.5 in. Hg] where you are operating, you’re probably not going to hit your specification consistently.” Further, measuring the difference in vacuum is not possible with typical vacuum gauges. Emanis uses an absolute pressure gauge, which measures the exact pressure in mbars and to within 0.001 in. Hg. (See “Double-bag infusion: Thickness gradient and pressure,” under Editor's Picks.") Unlike dial-type vacuum gauges, absolute gauges are unvented (venting reportedly introduces errors) and incur no delay, providing a more accurate understanding of pressure-change dynamics. Emanis notes, “I can repeat a particular laminate time and time again, consistently.”

Likewise, changes in ambient temperature and moisture and any differences between resin and tool temperatures will change the resin flow profile, making it impossible to replicate results consistently. Stored core and reinforcement materials must be protected against ambient moisture absorption and/or dried before infusion to avoid outgassing during infusion and cure, which causes voids. Even light can elevate temperature, if only a little, causing resin to react more quickly. According to Emanis, “If you test panels … in a very well lit lab and then move to a dimly lit open shop to run the full infusion, you won’t get the results you tested for.”

Related Content

New GTL breakthrough in composite tubing for liquid hydrogen in aircraft and space vehicles

Tests versus stainless steel tubing show 10 times faster chill down, fuel flow in 2 seconds and less boil-off for significantly faster fueling and refueling of LH2-powered space vehicles, aircraft and trucks.

Read MoreOrbital Composites wins award from U.S. Space Force to build space factories for antennas

Partners Axiom Space, Northrop Grumman Space Logistics and Southwest Research Institute will help advance ISAM technologies for kilometer-scale LEO antennas, space stations and GEO applications, targeting space factory in 3-5 years.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreHyImpulse, Adamant Composites linerless CFRP tank passes hydrostatic burst test

The liquid oxygen (LOX) tank, to be used in a HyImpulse smallsat launch vehicle, demonstrates the ability to withstand pressures well beyond the limits of its intended use.

Read More