AMRC Training Centre introduces composites apprenticeship opportunity

With partners McLaren and Teledyne CML Composites, the Training Center will train new composites technicians in South Yorkshire to build up the future industry workforce.

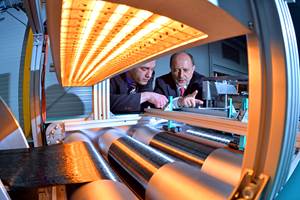

Working in partnership with McLaren F1, McLaren Automotive and Teledyne CML Composites, a new advanced level composites technician apprenticeship has been launched at the University of Sheffield AMRC Training Centre. Source | AMRC

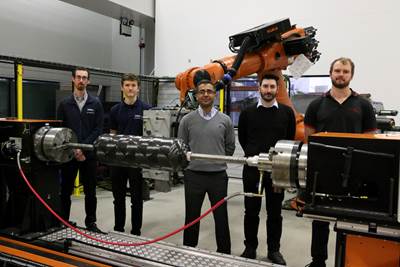

Together with U.K.-based McLaren Racing (Woking), McLaren Automotive (Woking) and Teledyne CML Composites (Wirral) the University of Sheffield Advanced Manufacturing Research Centre’s (AMRC, Catcliffe, U.K.) Training Center is delivering a new advanced level composites technician apprenticeship in South Yorkshire, in a move to sustain the longevity of the composites workforce. This adds to the metallic machining apprenticeship the Center is already delivering with McLaren.

The partners aim for more companies to come on board in the future. “Working alongside McLaren and Composites UK, a need for such an apprenticeship was identified to help fill the national skills gap of people in composites due to an aging workforce,” Nikki Jones, director of the AMRC Training Centre, notes. “Composites has always been a capability the AMRC has had a big focus on and as its new building is underway to deliver a new program called Composites at Speed and Scale [COMPASS], which is likely to provide a number of jobs in the region, we are acting now to build our expertise and capacity in composites to help supply the future workforce.”

Students who are undertaking the 36-month apprenticeship will engage in the production of composite components or products that are used in a range of applications, some of which include automotive, motorsport, aerospace, rail and renewable industries.

According to Piers Thynne, COO for the McLaren Formula 1 Team, McLaren Racing has led the way in pioneering advanced composite materials throughout its 60-year history, from introducing carbon fiber to the F1 car, to trialing innovative and sustainable alternatives like recycled carbon fiber on track. Similarly, Teledyne CML Composites has its own composites background, specializing in the manufacture of composites parts and assemblies on advanced aircraft platforms.

“Composite materials are critical in order for the UK to meet its net-zero targets and composites is an exciting and growing industry for young people to be involved in,” Matt Bradney, skills and workforce development director for Composites UK, adds. “There are various entry points, a key one being the composite technician apprenticeship. For the apprentice, learning and earning on the job is a great way to get a head start. For the employer, the new apprenticeship model launched by the AMRC gives flexibility in the delivery of the learning aspect, making it easier to get involved with a more efficient way to develop the workforce of the future.”

The first cohort for the apprenticeship started in September 2023, which includes an all-female group based at McLaren’s headquarters in Woking, alongside two other learners at the McLaren Composites Technology Centre (MCTC) in Sheffield. Opened in 2018, MCTC has established its focus in carbon fiber construction for the automotive industry and is where the McLaren carbon fiber architecture for the McLaren Artura high-performance hybrid supercar is constructed. Three more learners are placed with Teledyne CML at its base in Bromborough on the Wirral.

More information about the apprenticeships available at the AMRC Training Centre and how to apply is available via amrctraining.co.uk.

Related Content

NASA names university teams for aeronautics research challenges

As part of the agency’s University Leadership Initiative, three multidisciplinary teams will address topics related to growth in AAM, while a fourth examines electricity generation for future airliners.

Read MoreChemnitz University of Technology receives €6 million to expand research into "green" carbon fiber

Carbon LabFactory and InnoCarbEnergy project conduct R&D across entire value chain from raw materials through processes to structures and systems on a pilot line with technology demonstrators.

Read MoreInha University incorporates SwiftComp simulation software to virtually test composites

AnalySwift’s SwiftComp tool aims to mitigate the burden of costly experiments and enable accurate testing of woven and braided composite structures.

Read MoreThe Native Lab launches composites course training membership plan

Courses that touch on the fundamentals of composite materials, design, analysis and more are available for individuals and companies alike through TNL’s online platform.

Read MoreRead Next

Clogging the brain drain: Growing the composites workforce in a pandemic era

As Baby Boomers retire and high school and college graduates forestall their entry into the workforce, composites fabricators need to get creative to close the gap.

Read MoreAMRC, industrial partners develop Type IV hydrogen tank for long-haul vehicles

In the 12-month project, the University of Sheffield Advanced Manufacturing Research Centre (AMRC) has built prototype tanks and worked to build a secure U.K. supply chain.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read More