Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Share

Daher’s Shap’in TechCenter comprises an administrative building (left) and technical building (right) co-located with its composite parts factory (not shown). Photo Credit, all images: Daher

Image at top: Daher’s expertise spans not just thermoplastic composites but also thermosets, as shown in this co-cured integrated stringer wing skin for ATR 72 aircraft being machined.

Daher (Orly, France) is a unique Tier 1 supplier in the aerospace industry, operating not only as a leading aerostructures manufacturer, but also as an aircraft producer and provider of services including interiors installation and logistics. Founded in 1863, Daher has operations in 20 countries, with 90% of its €1.5 billion annual revenue derived from aerospace. It began aircraft manufacture in 1911 and now produces the TBM and Kodiak single-engine turboprop aircraft, launching the latest TBM 960 and Kodiak 900 in 2022. Daher also has a logistics business that designs and implements systems and services including transportation and installation to support manufacturing and operations mainly in aerospace and other high-tech industries.

Figure 1. ATR large composite structures, innovation. Daher has two decades of composites experience and a long history of producing and prototyping large structures and new composites technologies including thermoplastic composites (TPC) and welding as demonstrated for a horizontal tail plane (HTP) structure.

In addition, Daher is known as a supplier of equipment and complex metallic and composite assemblies for aircraft wings, fuselages, landing gear and propulsion. It has more than two decades of experience in composites and became an early leader in thermoplastic composites (TPC), having acquired Airbus’ workshop in Bouguenais, France in 2009. By 2015, Daher’s composite parts factory — down the street in Saint-Aignan-de-Grandlieu, outside of Nantes — had been recognized as France’s first “Factory of the Future,” due to its automated cells producing TPC clips for the Airbus A350 (see “Inside a thermoplastic composites hotbed”).

However, as can be seen in Fig. 1, Daher has long embraced large composite structures, as well as new technology and innovation. In 2021, CW wrote about the OOA rear spar and thick, high-load TPC ribs for Airbus’ Wing of Tomorrow program. Also in 2021, Daher launched three innovation centers: Log’in to reduce the environmental footprint of logistics, Fly’in for future hybrid propulsion and low-carbon aircraft and Shap’in to accelerate innovation in composites aerostructures. The Shap’in TechCenter sits adjacent to Daher’s Saint-Aignan-de-Grandlieu composite structures plant. This TechCenter has been designed, as described in Daher’s 2021 press kit and a 2022 article in Air&Cosmos magazine, to bring together skills and resources to accelerate putting innovative designs into production and with greater agility.

CW was invited to tour Daher’s Saint-Aignan facilities and explore how they are helping to fulfill its latest 5-year strategy to decarbonize aviation, including its own operations and those for its customers as well.

Shap’in TechCenter

CW’s guide is Michael Hugon, intellectual property manager for Daher. He explains that the concept for Shap’in came from the company’s restructuring of its industrial footprint following COVID-19. “We needed to create an excellence center to develop the innovative composite technologies that will make tomorrow’s eco-efficient products possible,” he explains. “We had seen that having a local ecosystem with both engineering and manufacturing is key for efficient development of composites solutions. The vision for Shap’in was to merge our teams to enable synergy between the design office, process department, materials department and manufacturing, in order to quickly develop new, high-value products.”

“So, we decided to develop the Shap’in TechCenter close to the factory in Saint-Aignan, with the advantage that here we can access the Nantes ecosystem, including Airbus, one of our biggest customers, but also partners like the IRT Jules Verne, Airbus Technocentre and Technocampus Composites, which includes R&D organizations like Cetim, and also academic/training centers like UIMM and Jules Verne Manufacturing Academy,” Hugon continues.

Opened in December 2022, the Shap’in TechCenter comprises the administrative building and the technical building. “The administrative building houses the R&D department, design group, materials and process team and advanced manufacturing engineering,” says Hugon. “And also the supporting administrative team, including purchasing and quality, so that we have everything we need to facilitate what we’re doing, both in the TechCenter and factory. And what we develop here could be implemented in any of Daher’s factories, such as Tarbes, Tanger or Nogales.” For example, Daher produces the carbon fiber-reinforced polymer (CFRP) tail boom and fenestron for the Airbus H160 helicopter in Tarbes, France, and CFRP spacers for the LEAP 1C engines in Nogales, Mexico. “The Shap’in technical building houses all the tools and means that we need for R&D,” continues Hugon, “allowing us to do prototyping without interrupting our production next door, so it’s more efficient.”

Demonstrator showroom, recycling TPC scrap

Figure 2. Shap’in technical building. The 1,600-square-meter production hall in the Shap’in technical building begins with a showroom of prototype and development parts behind which sits the Breton Matrix E1 and other machining cells, paint booth and curing lab. Returning back up the left side, enclosed labs include cleanroom, materials testing and characterization and another area (not shown) for acoustic panel drilling and coordinate measuring machine (CMM) inspection.

We exit the administrative building through a hallway and enter the technical building via a showroom for demonstrator parts (Fig. 2). A very thick (196-ply) TPC engine pylon was made in a project with IRT Jules Verne using automated fiber placement (AFP) of carbon fiber-reinforced Victrex (Cleveleys, Lancashire, U.K.) AE250 LMPAEK unidirectional (UD) tape and out-of-autoclave (OOA) consolidation. Nearby is the CF/LMPAEK air intake bulkhead for the 3.56-meter-diameter Rolls-Royce (London, U.K.) UltraFan engine demonstrator. It was made using 3D AFP and autoclave consolidation of Toray Advanced Composites (TAC, Nijverdal, Netherlands) TC1225 prepreg tape, demonstrating the replacement of a metal and thermoset (TS) composite assembly with TPC as well as the ability for Daher to make such large parts with double curvature. A compression molded TS composite strut panel is also shown, made using Hexcel (Stamford, Conn., U.S.) CF/8552 epoxy tapes in continuous and short fiber formats, and demonstrates capability for high-rate, net-shape processes.

Daher’s expertise in overmolding and injection molding TPC parts is shown in this eco-demonstrator rudder pedal for the TBM aircraft made using recycled CF/PPS from production scrap (left) and additional demonstrators made with R&D partners TPRC and IRT Jules Verne (middle, right).

An eco-demonstrator rudder pedal for the TBM aircraft was made using recycled CF/PPS material. “Production scrap was shredded, re-compounded and then used with injection molding to produce a part with complex geometry including curvature and ribs,” says Hugon. This pedal reduces cost by 75% and was certified in 2021.

Another table showcases two stamped and overmolded CF/PEKK parts, one developed in partnership with the ThermoPlastic composites Research Center (TPRC, Enschede, Netherlands), where it is a member, and the other with IRT Jules Verne. At the rear of this area, large bins of TPC scrap from the adjacent factory’s A350 clip and bracket production — skeletons from cutting 2D blanks and trimmings from 3D parts — are collected to demonstrate recycling in parts and process trials.

Machining thick parts

The area beyond the showroom and to the left houses a robotic system for high-speed drilling of holes in aeroengine nacelle acoustic panels. This machine will be supplied by Gebe2 (Montaigu-Vendée, France) and will also have spindles for sanding and trimming as well as ultrasonic cutting. An M3MH coordinate measuring machine (CMM) from Innovalia Metrology (Álava, Spain) is also being installed for dimensional control of prototype parts.

Across the main aisle of the open production hall, a large Breton (Castello Di Godego, Italy) Matrix E1 system has been installed (Fig. 3). “Here, we develop the process parameters, cutting tools and cutting conditions for thicker composite parts,” explains Shap’in machining expert, Sebastian Louvel. “We have integrated equipment to measure all the key parameters such as speed, power, vibration and cutting forces, which enables us to refine our processes. We can machine a part, evaluate the quality and then correlate that to understand the impact on the part’s mechanical properties.”

Louvel shows several samples being machined and tested, including part of the engine pylon that is 35 millimeters thick and an equally thick corner-shaped TPC part. “We are using these sections to validate the precision of our machining,” he explains. “We want to increase precision but also make the process more efficient yet robust versus production of thinner parts. For example, our current production machining would require 10-11 passes. We are refining how to machine this part in one pass while maintaining high precision and quality.”

That efficiency also includes topics like coolant. “We are looking at the design of cutting tools and investigating how to cut without using coolant, because the chips and machining scrap when using coolant must be cleaned before being recycled,” notes Louvel. Machining without coolant is not easy, however. “For these very thick structures, you must also quickly remove the chips and address the high temperatures generated.” He holds up a routing bit used on these thick TPC parts that is made by Mapal (Aalen, Germany), a company also researching how to machine composites without coolant.

In this area, there is also a 2.5-meter-long spar from the TRAMPOLINE project full-scale TPC torsion box, clamped into a metal machining jig. “We will also be able to manufacture our own jigs and tooling for our prototypes in-house,” notes Hugon, “which gives us speed in development.” Just beyond this area is a small machining booth and beside it, a small paint booth for applying adhesives and mastics.

Full materials characterization, CARAC TP

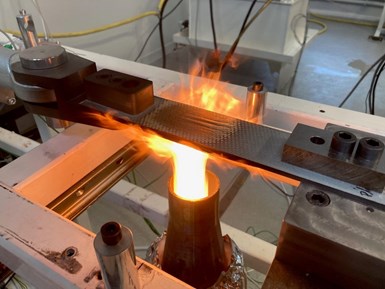

Testing of sub-scale welded TPC torsion box (top) as part of the TRAMPOLINE project and fire testing (bottom) as part of Daher’s CARAC TP program.

We move back across the aisle to an enclosed area that houses the materials characterization lab. There is a small, heated press for making test coupons and several climactic chambers for conditioning test specimens. One of the sub-scale welded torsion box assemblies sits on a table with sensors attached to it. “We have tested it to breaking,” says Hugon.

We walk through another door into an adjacent part of the lab that contains several dynamic scanning calorimetry (DSC) and thermogravimetric analysis (TGA) stations. “We can monitor the change of state in thermoplastic materials,” says Hugon, “from entropy through fusion, glass transition and crystallization. We also have rheometers for viscosity analysis. We are developing our own database correlating fundamental material behavior with time and temperature as well as degradation with exposure to temperatures above the glass transition.”

A huge amount of such work has already been completed as part of Daher’s CARAC TP project, which is not only completing the testing pyramid for certification of TPC structures in high-temperature engine and wing applications, but also the materials science, digital models and design methodologies to define the optimal parameters for processes like AFP, stamping and welding for each material and part. The project has already proven that high-performance TPC materials like PEEK, PEKK and LMPAEK don’t have the same degradation issue as epoxy composites under high temperatures and hot/wet conditions. However, Daher also wants to compare these with composites using new, fast OOA curing TS resins. “We want to stop just doing cooking using legacy recipes and instead develop physics- and data-based recipes to enable new composites applications,” says Hugon. “Instead of saying we have a competence in TPC stamping and welding, we can now say we have the knowledge to look at all materials and develop the part from beginning to end. We can pick the right material, the right process with the right parameters, we can perform design to manufacturing analysis for the part, drive its certification and know how it will perform in the end-use environment. This saves our customers time and money.”

Figure 3. Materials test lab. Daher is developing its own database of TS and TPC materials correlating materials science and process data with part performance in its materials lab.

At the far end of the materials testing lab, a digital electron microscope sits across from polished micrograph specimens. “We have all the polishing and sample preparation machines as well,” notes Hugon. There is a station for measuring fiber content using chemical digestion as well as two ZwickRoell (Ulm, Germany) machines with extensometers — one for hot testing up to 150 kilonewtons and the other capable of hot/cold testing up to 250 kilonewtons.

Cleanroom, curing, welding

Figure 3. Curing center. Daher’s curing center enables comparing consolidation in and out of autoclave.

Next to the testing lab is the 130-square-meter cleanroom, the last enclosed area at the end of the tech building. We step outside through a door to see the exterior prepreg storage freezer. Back inside, across from the cleanroom is a 2-meter-diameter × 4.5-meter-long autoclave and two ovens. The first, supplied by Sat-Thermique (Méry, France), goes up to 400°C for consolidating TPC parts and the second, supplied by France Etuves (Chelles, France), is for TS composite parts. “We can have perfect consolidation conditions in the autoclave and then compare that with our ability to consolidate without an autoclave,” says Hugon. “We use this to evaluate our processes with different materials and part configurations.”

One of the processes being evaluated is welding of TPC components. “We have a small welding bench to create coupons,” says Hugon, “but for the demonstrators in the TRAMPOLINE project, we asked our partner and subsidiary, KVE Composites [The Hague, Netherlands], which has the robotic induction welding setup and expertise, to do the structural welding. We co-engineer the parts and assembly process with them to challenge both our design and the welding technology. This approach increases the maturity of the part and process in parallel. We then make the components and send them to KVE. They weld them and send the assemblies back for us to test and validate the design and stress analysis and mature our design guidelines.”

Hugon explains that KVE Composites remains independent as a technology provider, “but we collaborate to mature the welding technology and the technology application at the same time.”

Composites factory

We exit the Shap’in TechCenter and cross the parking lot to enter Daher’s production factory midway along its northeast length (Fig. 4). A small reception area displays an inner bypass duct (IBD) for Pratt & Whitney 812/814/815 engines. Other high-temperature TS composite applications include strut panels and a one-piece barrel for the LEAP 1B aeroengine nacelle, a rear secondary structure for Airbus A320 and A350 jetliners and APU plenums for Airbus, Boeing and Dassault Falcon business jets. Daher also makes main landing gear doors for the A350 (in Tarbes), the outboard wing panels and spars for the ATR 72 turboprop aircraft, horizontal tail plane (HTP) panels for the Dassault Falcon 900/2000 series jets and winglets for Gulfstream G700 business jets, as well as the upper beams for the A380 center wing box. Although the A380 is no longer in production, the part showcases Daher’s capability: 7 meters long, comprising 11 parts, weighing 60 kilograms and made with resin transfer molding (RTM).

Thermoplastic parts made in this facility include A350 fuselage clips and the cockpit floor for the A400M military transport. Materials used include PPS with carbon fiber fabric and also glass fabric used as an isolation layer to prevent galvanic corrosion when clips have an interface with aluminum. Daher also applies materials such as lightning strike protection (LSP) mesh. It buys most of its thermoplastic composite materials as 3.6-meter-long Cetex organosheet panels from TAC, but also makes some materials in-house. “We make the CF/PEEK UD panels for the A400M cockpit floor in-house,” says Hugon. “We also prepare some materials for the ATR wing panels, which are made using first-generation automated tape laying [ATL] machines that require tapes and patches premade to a certain format.” He outlines the basic process chains on the production floor:

- TS composites: Raw material, ply cutting, layup (hand, AFP, ATL), autoclave/oven, trimming, dimensional inspection and nondestructive testing (NDT), paint and final assembly.

- TPC: Raw material sheets, cut 2D blanks, stamp and trim 3D parts, quality control (ultrasonic testing (UT) C-scan tanks/robotic squirter cell) and finishing.

A350 clip production

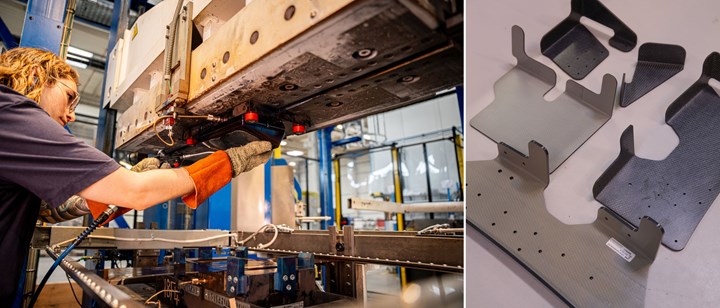

This production takes up most of the TPC half of the building. At the far right, incoming Cetex sheets are inspected and then cut with a Flow Waterjet (Kent, Wash., U.S.) or Mécanumeric (Albi, France) waterjet into 2D blanks that are placed in a rack to dry and then collated into sets of 6-10 plates per material batch. Cutting scrap is taken to the Shap’in TechCenter. The sets of plates are then loaded into bins that will be processed through two automated stamping cells (Fig. 5), each equipped with two FANUC (Echternach, Luxembourg) multiaxis robots, infrared ovens to preheat the blanks and Pinette Emidecau Industries (PEI, Chalon sur Saône, France) 55- and 75-ton presses to stamp into 3D parts. There are four additional presses, including a 120-ton R&D press and a 1,000-ton press for large structures.

As we approach one of the stamping cells, Hugon points out that one robot manages the tools, while the other loads and unloads the tools throughout preheat and stamping. “Tool management is key for this type of heavy serial production,” he explains. “The tool must be changed every 10 to 15 parts. So, the challenge is to have the old tool removed and the new tool transitioned in without stopping the process.” The blanks are preloaded onto a fixture with high-temperature Thermalimide release film made by Airtech International (Huntington Beach, Calif., U.S.).

Figure 5. High-volume TPC clip production. Each automated cell shown above uses two robots (yellow). One, at lower left, shuttles blanks and parts in and out of the blue-framed preheat oven on the right and the stamping press in the center background. The other (center background behind the press) changes out tools every 10-15 parts.

Looking at the cell, the tool handling robot and its bank of tools are behind the press. On this side of the press is the robot which cycles materials and parts through the cell. It moves through a set of steps choreographed to match the cell’s cycle time. It grabs a fixture preloaded with 2D blanks from a table in the materials/finished parts window; places the loaded fixture into one of the preheating ovens; removes a finished part from the press and places it onto the materials/parts table; picks up another fixture with pre-loaded blanks and places that into a second IR oven; and removes preheated blank and places that into the press. It repeats this sequence every 3-5 minutes, depending on the clip or bracket being made. “The ovens can preheat up to 200°C,” says Hugon. “The temperature of the preheated blank and the press during stamping are aligned to manage the required crystallinity of the thermoplastic matrix for each type of part.”

In-line machining is completed in a Belotti (Suisio, Italy) FLA 3018 high-speed, five-axis CNC machine. Parts are then scanned for dimensional accuracy using a Hexagon Manufacturing Intelligence (HMI, Stockholm, Sweden) CMM system. Further machining is completed in one of three CMS Industries (Zogno, Italy) machining cells, after which parts are inspected using an automated C-scan UT cell with water tank. An adjacent vertical automated cell with water squirter for single-side UT is used to inspect the flat panels and cut blanks for the A400M cockpit floor panel.

Note, Daher develops most of its NDT equipment itself. “Once we have the concept of the NDT cell, we contact an integrator,” explains Hugon. “For example, we worked with PEI for the large pool of NDT cells for the ATR wing panels and spars, Dassault HTP panels, IBD parts and large R&D parts. Adjacent to this NDT area is a machine to apply adhesive and fasteners for assembly of multipart A350 clips.

At the left rear of the TPC production area is where the cabin floor for the A400M is assembled. This is one of the first thermoplastic composites Airbus developed, dating back to roughly 2005, and it uses UD CF/PEEK tape. “We do everything in-house: layup, consolidation of the panel, cutting and some stamping,” says Hugon. “The stamped part is the biggest part of the floor and is key for stiffness. Then everything is assembled with rivets, and you see the part is loaded into this large fixture that helps us to drill and complete assembly.”

As we walk back toward the front of the building, we pass a bank of digital screens displaying production key performance indicators (KPIs). “This is our Manufacturing Engineering System [MES] display where we are continuously monitoring production to help manage the flow of each task and each step of the various processes,” explains Hugon. “At each point, the technicians scan the barcode for each material or blank or stamping. This then goes into the system so we can see where and when it has been loaded and where we are in production for each batch versus our work orders. If there is a problem, we can see that and have our technical team work to resolve it. So, it’s important that they are already connected and have the data to act as soon as possible and troubleshoot whatever issues may arise. This results from the R&D project ODDICEA [Operational Digitalization for Databased and Inter-Connected Efficient Activities], another example of synergy between the factory and Shap’in teams.”

TS composites production

We are back at the front of the factory and facing its rear wall. Between the TPC and TS production areas is a 3D waterjet trimming cell, and to its left is the large 3,600-square-meter cleanroom, equipped with overpressure to prevent contaminants as well as temperature and humidity control. To our left, across from the cleanroom, is the 21-meter-long, 4-meter-diameter autoclave. In front sits a large metal cart on wheels, similar to a short, flat railcar (Fig. 6). “We fit in two of these at a time to cure the 1.2 × 8.5-meter wing panels and 0.4 × 8.5-meter wing spars for the ATR 72,” says Hugon.

Beyond the autoclave are four ovens: one 3 × 6-meter 400°C oven from France Etuve for TPC and three 2.5 × 2.5-meter ovens dedicated for curing RTM parts. This area is filled with cured parts ready for machining and machined parts ready for final inspection. A machining cell for trimming and drilling finished parts after cure fills the corner. We turn right and walk toward the rear of the building. On the left are tools for laying up and assembling the ATR wing spars and stringer-stiffened wing panels. Just past these tools is an infrared hot drape forming (HDF) station by Elmetherm (Saint-Auvent, France) for debulking and forming the ATR wing stringer preforms. On the right are ATL and AFP cells which create the laminate sheets for the ATR wing skins, stringers and spars, as well as other parts.

The ATR 72 wing parts business was transferred from Airbus in 2012, explains Hugon. The wing skin layups are made using “BMO” brand machines developed in the 1990s by Brisard Group (Capdenac, France). These are the machines referred to earlier, where premade tapes and patches are loaded into a cassette and then applied by the ATL head which is installed on a gantry. The system was originally designed to use prepreg tape from 25-150 millimeters wide, with one cassette capable of holding 300 meters of tape.

These ATL cells not only make the ATR wing skins, but also the C-shaped preforms that will be co-cured to form the integrated stringer-stiffened panels. These preforms are placed upside down and side by side into an assembly tool, the flanges mated to form the stringers. A noodle is placed to fill the small triangular gap in between. The assembly tool is then lifted by gantry crane and inverted to mate the stringer preform assembly onto the ATL wing skin. The skin-stringer assembly is then vacuum bagged and co-cured in the autoclave.

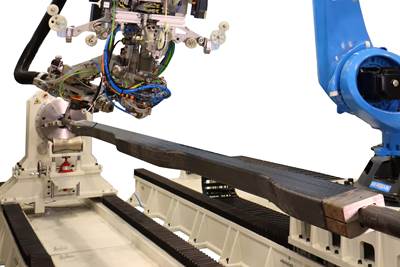

On the other side of the BMO tape laying cells is the KVE Composites induction welding station (Fig. 7). “Here, we can create standardized welded coupons for testing,” says Hugon. “It is a simple setup and stays very busy.” Across the aisle is an ATL machine from Fives Liné (Paris, France), used to lay up the U-shaped ATR wing spars. These layups are debulked in the HDF station before being vacuum bagged and autoclave cured.

Next to this cell is an enclosed room housing a Coriolis Composites (Quéven, France) C1 robotic AFP machine. “The C1 can be used with thermoset prepreg, dry fiber or thermoplastic prepreg tape,” says Hugon. “For TPC and dry fiber we use laser heating and IR heating for TS prepreg. The C1 can apply up to six tapes simultaneously and can cut each tape independently. We can use the toolholder and apply tapes onto a rotating tool, or we can lay onto the flat release table. For now, we are only using this C1 machine for R&D, but it stays occupied 100% of the time.”

Figure 7. KVE INDUCT welding and Coriolis C1 AFP cells. Currently used for R&D, these two cells in Daher’s production factory stay occupied as it matures TPC structures for future production.

We walk back out into the main aisle facing the wing panel and spar layup tools again and turn right to proceed toward the back of the building. Just beyond the HDF station on our left are the automated machines that produce the tapes used by the BMO cells. Beyond that is the IBD production area where various parts are being hand laid. There is also a 3D control station for IBD parts in this area comprising an HMI Advantage system for CMM inspection of large parts.

On the right is production of the A350 air inlet made using RTM. Beyond that is a trimming cell for these parts and a large NDT area. Hugon notes that parts are first inspected using the large water-filled C-scan tank. If areas of concern are identified, then parts are placed on tables in this area and technicians do localized A-scans for a more detailed evaluation. Next, we pass production of a triangular fairing for the ATR aircraft, also made using RTM. Hugon notes this is a fairly simple part, as we watch technicians lay dry fiber layers into tools.

The final area we tour contains preparation for painting, as well as finishing and shipment. As we return to the entry, Hugon points out the plant is at roughly 80% capacity. What happens when business increases? “We are already rearranging and streamlining to be more efficient and free up additional space,” he says, pointing to the northeast corner next to the administrative offices. “We also have additional land here where we can add more factory space if needed.”

Decarbonization, lightweighting engines and wings, faster production

Daher’s vision for these two facilities, says Hugon, is that they work together to push the boundaries of TPC and TS composites and their sustainability, including recycling and lower energy use. “We want to be the best,” he adds. “Now, everyone talks about decarbonization, but we started looking at this more than 15 years ago, working to design and produce lighter aircraft structures, which remains one of the best ways to reduce carbon emissions. This is in our DNA, and we continue to challenge the load capabilities of structures to have bigger leverage on this reduction of weight. That is also why we are working on wing structures and with engine manufacturers to increase composites inside and around the engines.”

Thermoplastic welding is another means to reduce weight by eliminating thousands of metal fasteners. And it also speeds up production, removing numerous steps in the parts supply and process chains. “We believe that for a new A320-type aircraft to be realized in 5 to 8 years, thermoplastic composites will be a game changer, to enable not only higher production rates, but also the best cost and weight,” notes Pascal Laguerre, CTO for Daher.

Dominique Bailly, Daher VP of R&D, agrees, but adds, “the main challenge for the aviation industry is to increase decarbonization and reduce environmental impact. All our projects are part of this effort. The new composites knowledge and technologies that we are demonstrating provide gains in performance and in limiting the ecological impact of air transport. This is the key for future aerostructures, and what Daher is committed to. We will continue to maintain our leadership in a wide range of technologies, and to drive innovation that empowers aviation to be the best it can be.”

Related Content

Toray develops high-speed thermal welding for thermoset composites

Novel technology forms a thermally weldable layer on the surface of carbon fiber-reinforced thermoset or thermoplastic components, further validated by demonstrators.

Read MoreAitiip Technology Center reports dismantling of thermoplastic parts using resistance welding

Clean Sky 2 HELACS project aims to enable improved recycling of composite components at aircraft end of life.

Read MoreNovel insert technology enables arc stud welding with composites

FAUSST technology enables fast, reliably welded connection of metal components in composite structures.

Read MoreSTUNNING project completes lower half of MFFD

Clean Sky project has delivered the 8 × 4 meter welded aerostructure component, aided by advanced thermoplastic composite technologies and smart robotics.

Read MoreRead Next

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreDaher lays the cornerstone for Shap’in composite aerostructures innovation center

Based in the Nantes, France region, the Shap’in TechCenter combines R&D and a production plant within a single facility, capitalizing on Daher’s composites expertise.

Read MorePlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read More