FAUSST local insert patches from Hyconnect enable rapid and reliable arc stud welding for high-strength, lightweight metal connections to composites. Source (All Images) | Hyconnect GmbH

Mobility and infrastructure are changing, and with them designs and materials. To meet the challenges of sustainability and efficiency, manufacturers seek to use optimized material combinations. Metal structures must be connected with lightweight components such as fiber-reinforced composites. This has mainly been solved with adhesives and/or drilled holes with mechanical fasteners. However, these methods can increase weight, labor, cost and production time.

FAUSST technology, created by Hyconnect (Hamburg, Germany), has been developed to enable joining metal elements to composite materials without the complexity of bonding or riveting. Easily integrated during composites layup, demolded parts have integrated metal connection points enabling a wide range of possibilities for joining to steel or aluminum. Moreover, FAUSST makes composites weldable.

Developing FAUSST, stud welding

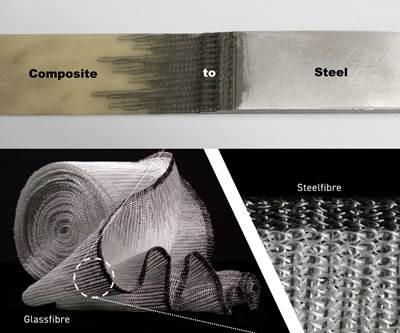

The technology’s name derives from the German-funded Fiber and Steel Standard (FAUSST) joint project, which resulted in a hybrid knitted fabric that combined glass and steel fibers. The glass side of the fabric is infused into a composite part while the metal side enables welding. This approach can achieve, for example, welding of composite elements onto metal ship decks and hulls.

Hyconnect was founded in 2018 to advance and prove out that technology. The potential to use FAUSST was seen early on as a solution to the significant engineering and manufacturing challenge of how to integrate local inserts for connecting metals and composites. The FAUSST local insert patch is designed to enable arc stud welding and streamline this process in composite structures.

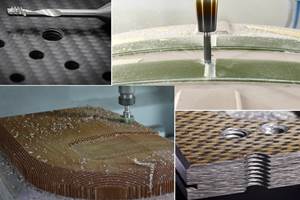

Stud welding (also known as electric arc or drawn arc stud welding) enables metal fasteners — such as weld studs, weld pins and tapped studs — to be welded onto another metal object at lightning speed. A welding gun or tool (opening image) is used to push the stud against the workpiece and create an electric arc between that surface and the end of the stud, melting both. The stud is then forged into the molten pool, creating, as the material cools and solidifies, a reliable and durable welded attachment that is used widely in industry. There is no risk of fire with composites, as the stud welding process is very accurate and completed within a metal cylinder which also contains inter-shielding gas that immediately cools down any potential sparks.

How FAUSST local insert patches work

The FAUSST local insert patch (Fig. 1) comprises two layers of reinforcing fibers (e.g., glass or aramid) stitched onto a perforated metal plate which has a thin metal disk welded to it. This disk is the base for the subsequent welded metal fastener or component. The two layers of glass or aramid fabric are stitched together to not only affix the metal disk within the patch, but they also contribute to the strength of the patch and prevent delamination between the metal elements and the composite.

The patch is then placed into a composite layup for subsequent molding processes, such as hand layup (Fig. 2), resin infusion or resin transfer molding (RTM). The local insert patch is designed to be very thin — 1.5 to ±0.2 millimeter — and can be used in laminates at least 2 millimeters thick.

As the patch is molded into the composite laminate, layers of glass fiber and resin will also be on top, covering the metal plate. After the composite part is cured and demolded, this covering layer needs to be removed, and can be machined using a disc grinder.

The insert is then ready to weld. A wide array of available nuts and bolts can be welded onto the patch, enabling the integration of even high-mass components.

Figure 3. Stud welding on FAUSST local insert in a composite part using a Soyer PH-9 SRM stud welding gun.

Adaptability, strength

There are many options to adapt the basic local insert patch to specific applications. Fibers for the fabric layers can be glass, aramid, basalt or carbon fiber. However, for the latter, potential for galvanic corrosion with aluminum and plain steel can be an issue. For this reason, the steel fibers used are treated with a sizing that will prevent direct contact with carbon fiber. Welded FAUSST local insert patches have successfully withstood salt spray tests with no corrosion. Using FAUSST with aluminum is also being developed, with samples currently undergoing salt spray testing.

Figure 4. Example of FAUSST local insert using steel fiber on a carbon fiber/PA6 thermoplastic composite. Steel fiber is stitched to a carbon fiber layer (left), a metal disk is then resistance spot welded onto the steel fiber (center) and the patch is integrated into a composite (right), ready to be welded to a metal fastener or component.

FAUSST local insert patches can also be used in thermoplastic composites. In this case, the perforated plate is removed, and steel fibers are directly stitched to a carbon fiber layer using tailored fiber placement (TFP). A metal disk is then welded to this steel TFP layer using resistance spot welding (commonly used in the automotive industry). As with thermoset resins, the insert patch can be integrated to the composite but using thermoplastic composite molding methods. Fig. 4 shows such an application with a carbon fiber-reinforced polyamid 6 (PA6) composite.

Figure 5. Testing of a glass fiber FAUSST local insert patch was performed by FIBRE using a test rig in a standard tensile test machine and showed a tensile strength >13 kilonewtons, which exceeded the yield strength of the stud-welded bolt.

FAUSST local insert patches have shown high strength in testing. Tests on samples using glass fiber patches were carried out at Faserinstitut Bremen (FIBRE, Bremen, Germany) using a test rig in a standard tensile testing machine (Fig. 5). Load was applied at 2 millimeters per minute. The tensile strength of the stud welded attachment exceeded 13 kilonewtons as well as the yield strength of the bolt. This tensile strength is in the range of an unaged high-strength bond using epoxy adhesive such as Sika-Force 840 (Sika, Baar, Switzerland) according to its data sheet.

Advantages, applications and future outlook

FAUSST local inserts have been tested in glass fiber-reinforced composite panels with fire protection for rail car applications. The panels used standard epoxy resin and Saertex Leo-coated fabric (Saertex, Saerbeck, Germany)

as a top layer, while the welded bolt fastener was protected by Flammadur A365 polyurethane sealing compound. The panels successfully passed the test, withstanding more than 30 minutes of fire without failure. Thus, due to FAUSST-enabled fastener integration, load can be safely carried by these panels even under severe fire incidents. Additional benefits include:

- Simple installation — Enables quick and easy attachment of fixtures to composite panels, reducing the need for additional support structures.

- Enhanced durability — By distributing load more evenly, the lifespan of the composite panels and the attached components is increased.

- Versatility — It is suitable for a wide range of applications, from small boats to large aerospace components, offering adaptability across different industries.

More applications are being developed for marine, ballistic panels, and the oil and gas industry. As industries continue to push the boundaries of what is possible with composite materials, local insert technology will become increasingly crucial. With weldable inserts, composites may still be a solution when adhesive bonding or mechanical inserts can’t be used.

About the Author

Dr. Lars Molter

Lars founded Hyconnect GmbH (Hamburg, Germany) in 2018. As a Ph.D. engineer, he worked in materials, production and design of ship and offshore structures for more than 10 years, including as a naval architect for the Center of Maritime Technologies (CMT), specializing in lightweight construction, resource efficiency and material joining. He has designed and led several large European research activities and now advances new lightweight designs via innovative metal-composite joining solutions.

Related Content

MM-Welding solution automates, functionalizes composite joining

Ultrasonic joining has been used for decades, but is now being advanced to enable smart, automated fastening in composites and multi-material assemblies.

Read MoreCreating a composite battery insert-stud solution for EV trucks

Bossard worked with an OEM and Tier supplier team to meet tight electrical insulation and packaging tolerances while reducing tooling, molding and assembly costs.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreRead Next

Removing barriers to lightweighting ships with composites

EU consortia propel large demonstrators, new technology and affordable certification.

Read MoreConnecting composites to steel

Hyconnect combines glass and steel fibers with welding to lightweight structures.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More