Inside Teijin’s thermoplastic tape expansion

Teijin is qualifying its second thermoplastic tape line in Heinsberg, Germany, that will significantly expand the company’s presence in this material segment.

Share

The hallmark of Teijin’s new thermoplastic prepreg line in Heinsberg, Germany, is its ability to produce very wide tapes — up to 24 inches wide. The line also offers unprecedented process and quality control in thermoplastic unidirectional (UD) tape production. Photo Credit, all images: Teijin Carbon Europe

It is expected that thermoplastic composites will play a larger and critical role in the fabrication of primary structures for a variety of next-generation aircraft, ranging from large commercial jetliners to small electric vertical takeoff and landing (eVTOL) aircraft that will be the core of the emerging advanced air mobility (AAM) market. Meeting this demand will require development and manufacture of thermoplastic tapes — unidirectional (UD) and multiaxial — that meet increasingly stringent quality requirements.

It was with these challenges in mind that Teijin Carbon Europe GmbH (Wuppertal, Germany) recently installed and commissioned a second thermoplastic tape line in its Heinsberg, Germany, facility. The first line, commissioned in 2011 and qualified for a Boeing application, is designed to provide thermoplastic tapes in quantities and widths adequate for research and development (R&D) and low-volume production purposes.

The second line, commissioned in 2019, uses the same manufacturing technologies as the first line, but at a scale, speed and consistency that represents a significant improvement across the board in manufacturing capability. Willem Jan ter Steeg, general manager development at Teijin Carbon Europe, introduced CW to the company’s new carbon fiber thermoplastic tape line via video and walked us through the system and its capabilities.

Wide, fast, long, repeatable

As he starts his tour of the line, ter Steeg notes that the process control offered in the new line provides Teijin unprecedented ability to quickly and consistently manufacture thermoplastic tapes that meet stringent quality standards for width, thickness, areal weight, resin distribution, fiber volume fraction (FVF), crystallinity and porosity.

First, and most notably, the new line can produce tapes in widths — 12 or 24 inches — not commonly found in the thermoplastic composites supply chain. Second, ter Steeg notes, the new line offers substantial flexibility, including up to 220 creel positions and the ability to adjust humidity, temperature, spreading parameters, tensioning and matrix content. “We have the possibility to go between 34 and approximately 40 or 42% matrix content,” ter Steeg says. “Theoretically we can go to 50%, but there is no request for this.” The line typically produces tapes with fiber areal weights (FAW) of 97-200 gsm; FAW of more than 200 gsm has been demonstrated.

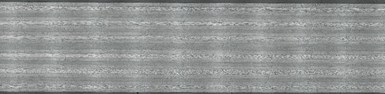

This micrograph of a thermoplastic tape from Teijin’s new line demonstrates the consistency and uniformity of the manufacturing process. Thermoplastic prepreg tape quality has been steadily improving over the last decade.

UD carbon fibers are the primary reinforcement processed on the new line, though other materials like aramid can also be used. The carbon fibers come from Teijin directly, which is among the largest manufacturers of carbon fiber in the world.

As fibers emerge from the creels and are tensioned into the line, they enter the impregnation unit. Here, ter Steeg notes that the impregnation unit disperses the resin matrix as a powder that is then mixed with an emulsifier and applied to the fibers. The company favors this method — as compared to melt impregnation — as it provides a more consistent and even dispersion of the polymer.

Teijin is primarily prepregging polyetheretherketone (PEEK) and polyphenylene sulfide (PPS) on this line, with low-melt polyaryletherketone (LMPAEK) and polyetherketonketone (PEKK) processed less frequently. Other resin matrix systems, ter Steeg notes, can be processed as well, but only if they are compatible with the emulsifier in the slurry.

Alfonso Lopez, aerospace marketing engineer at Teijin Carbon America, says, “The system that we’re talking about here is really very excellent for higher performance polymers, simply because they’re so difficult to handle. The quality of the tape manufactured in this particular method I think is really suitable and amenable to the quality that aerospace requires.”

Regarding non-powder/slurry impregnation, ter Steeg says, “Of course we are also looking into melt impregnation as an alternative to powder, but at the moment we do not have internal capacity with that technology. But we are watching this very closely.”

Following impregnation, the tape is passed through a dryer and then into a high-temperature oven, which does three things: melts the polymer to ensure homogenous polymer impregnation; helps minimize voids; and promotes proper crystallinity of the matrix. “With the oven we make sure we have the full impregnation of the molten polymer into the tape,” ter Steeg says, “and then of course we also handle the tape in such a way that we have the lowest possible amount of voids.”

Post-oven, the tape is trimmed to length — with offcuts collected and recycled as short fibers for injection molding — followed by laser-based width, thickness and areal weight measurement. “There is correlation of the width with the thickness, so we can basically predefine the fiber areal weight,” ter Steeg says. “And afterwards, we do measurements in the laboratory to ensure that we have the exact fiber areal weight and the exact resin content.”

The tapes are then wound onto spools at the end of the line. “This is the 24-inch-wide roll,” ter Steeg says, pointing to a roll of tape at the end of the line. “We have 115 grams per square meter of PPS tape. Currently, this one is nearly 900 meters long without any [defect].” He adds that the line can produce tapes 2.5 kilometers long, without defect or interruption.

The speed of the lines cannot be revealed, but ter Steeg did claim that it can produce thermoplastic tapes at a rate greater than Teijin’s competitors. “The evaporation of volatiles from the slurry is the only limit on speed,” he notes. The total capacity of the line varies by the areal weight of the material being produced, but ter Steeg reports that the system, at maximum throughput and maximum areal weight, can produce up to 320 metric tons per annum.

In a control room adjacent to the tape line, Teijin technicians continuously monitor all manufacturing parameters, ultimately providing all of the production data needed for full material traceability. “This is critical of course for aerospace, as you know,” ter Steeg says, “to ensure that everything is traceable. So this is why we do have the continuous monitoring of all the essential data.”

In terms of overall product quality, Lopez says PEEK is the standard against which all other tapes are measured. PEEK crystallinity, he notes, is the most consistent of the three resins processed most frequently. “PEEK is the baseline because the crystallinity rate is so high that it really makes it amenable for welding and forming with a consistent degree of crystallinity, regardless of the rate at which you’re cooling,” he says. “That’s not necessarily the case with PEKK and low-melt PAEK, where you have to be more careful how you cool it. However, with the line that we have here, we can control the thermal history, so we can get materials off this line that have zero cold crystallization.”

The bottom line, ter Steeg says, is that the new line offers unprecedented process control options that produce highly consistent tape quality. “The length, width and speed at this quality is unique in the composites industry,” he says. “We are getting closer and closer to thermoset tape quality.”

Qualification, applications and the future

As the aerospace industry recovers from COVID-19 and as Boeing and Airbus consider new aircraft programs that are certain to expand use of thermoplastic composites, Teijin is watching the market for signals about the fiber/resin mix that will be most in demand. Jean Philippe-Canart, aerospace marketing at Teijin Carbon America, says Teijin’s PPS tape “has had good success getting to programs quickly, so PPS is kind of opening the door for us to some other applications, like secondary structure or interior structure in aerospace. And then you have industrial applications like tape winding to make pipes and tubes.” Canart also notes that carbon fiber/PEEK is attractive for applications that require use of machinable blocks of composite materials.

PEKK’s future, Canart says, is somewhat in doubt, based on how Teijin sees the market evolving. “We see PEKK being a bit squeezed in between PEEK and low-melt PAEK,” he says. “If you want a really low-melt material, low-melt PAEK tends to see more benefit than the normal PEKK. And if you want high performance, we still push PEEK.”

Teijin has supplied this new wide tape to A&P Technology (Cincinnati, Ohio, U.S.), which braided it into intermediate formats for use and evaluation by thermoplastic composites fabricator ATC Manufacturing (Post Falls, Idaho, U.S.). Preliminary qualitative comparisons of UD, fabric and braided reinforcements used to manufacture stamp-formed leading edge ribs were presented at the American Composites Manufacturers Assn. (ACMA, Arlington, Va., U.S.) 2022 mobility conference by Teijin’s Lopez. Teijin is also involved in another project to braid 0.125-inch carbon fiber/thermoplastic tubes in lengths of up to 1.2 kilometers.

On the industrial side, ter Steeg says PPS is proving highly attractive. “What we see in the market is that there’s demand for a polymer with high resistance to chemicals and also low moisture pickup, so for things like pumps we also see a very high demand,” he says. “People are looking here for the lowest total cost with a high-quality material.”

In the fast-growing hydrogen market, Canart says Teijin is evaluating application of thermoset and thermoplastic composite materials for cryogenic hydrogen storage pressure vessels. “That, of course, presents an additional complexity,” he says.

The end market Teijin is watching very closely, Canart says, is AAM, which could demand much of the thermoplastic composites supply chain. “What does AAM want and need?” Canart asks. “Will it be a standard high-performance polymer, or is there maybe room for another polymer?”

This aerospace rib was stamp-formed by ATC Manufacturing using Teijin’s UD thermoplastic tapes braided by A&P Technology. Teijin has conducted preliminary qualitative assessment of the material to verify its capabilities in high-performance applications.

The answer to that question will guide Teijin’s next steps in Heinsberg. A third line is possible, ter Steeg says, assuming the demand is there. And what about wider tapes? The 24-inch-wide tape Teijin currently produces is appealing for a lot of reasons, ter Steeg says. It meets the needs of many applications and it’s relatively easy to handle. Going to a 36-inch width, he argues, introduces consolidation, shrinkage and handling challenges. Further, he notes, it is possible to create a wider tape by welding two narrower tapes. That said, “everything is in the picture,” he notes. “We are open to many possibilities.”

Related Content

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Thermoset-thermoplastic joining, natural fibers enable sustainability-focused brake cover

Award-winning motorcycle brake disc cover showcases potential for KTM Technologies’ Conexus joining technology and flax fiber composites.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)