JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

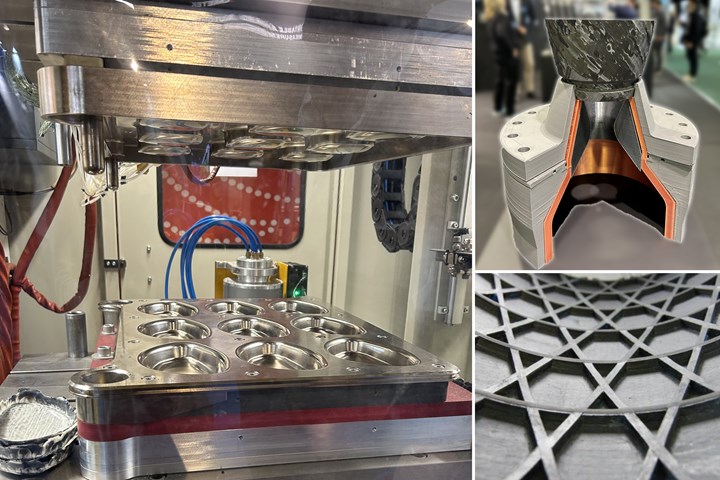

Highlights from JEC World 2024 (left, clockwise): Unwind3D induction-heated Spidui molding cell for thermoplastic composites; DLR’s C/SiC ceramic matrix composite (CMC) rocket nozzle extension and composite anisogrid structure made by CIRA using novel parallel winding of dry fiber and resin infusion. Source | CW, CIRA

JEC World 2024 (March 5-7, Paris, France) maintained its reputation for displaying myriad eye-catching composite parts and developments. Sustainability continued to be a common theme and there were numerous hydrogen tanks on exhibit. Here, I share a selection of my highlights from the show.

TPC development: Deep draw RCF parts, CF/PEKK aerospace demonstrator

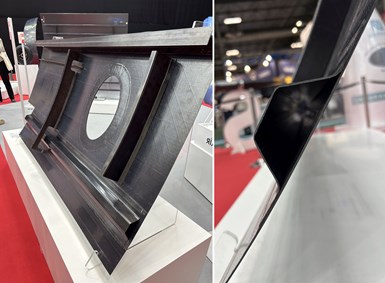

ATC’s deep-draw demo parts are made without preforming, directly stamping rCF nonwoven mat converted into KyronTEX thermoplastic sheet with a PPS or PEI matrix. Source | CW

ATC Manufacturing (Post Falls, Idaho, U.S.) displayed deep-draw thermoplastic composite (TPC) parts made using KyronTEX materials supplied by Mitsubishi Chemical Group (MCG) (Tokyo, Japan). These materials combined recycled carbon fiber (rCF) with polyphenylene sulfide (PPS) or polyetherimide (PEI) polymers in a mat product form, targeting secondary structures in aircraft interiors. The lofted, nonwoven rCF materials use fibers 1-2 inches in length and are supplied at 250 and 500 gram/square meter areal weights. “We wanted to form deep-draw shapes rapidly and economically in one step instead of first consolidating a preform and then stamping,” explains David Leach, director of business development for ATC. “We developed a method for direct stamping the TPC mat material that can produce high-quality parts in a 5-minute cycle time. We have a long history of forming TPC parts and understand how parts made with fabric and unidirectional [UD] tape can form wrinkles in corners. But this mat works really well. We’re also working with Mitsubishi on a second variant where we combine fabric with the rCF mat to provide increased stiffness.”

ATC used its flat CCM machine to produce the CF/PEKK omega stringers for the HEICoPAS project fuselage panel demonstrator. Source | CW

ATC Manufacturing was also a key partner in the HAICoPAS project TPC fuselage panel demonstrator displayed in the Mobility Planet at JEC World 2024. The demonstrator is made from HexPly thermoplastic prepreg tapes comprising Hexcel AS7 and IM carbon fiber with Arkema Kepstan polyetherketoneketone (PEKK) polymer (CF/PEKK). Components were produced by different partners and processes:

- Omega stringers by ATC using continuous compression molding (CCM)

- I- and T-stiffeners by Hutchinson using pullforming

- Z-frames by Daher using press stamping

- Fuselage skin and C-frames by Hexcel using an out-of-autoclave (OOA) process

These were joined using ISW induction welding developed by Institut de Soudure and Arkema. Additional consortium partners included: Coriolis Composites, Ingecal, Pinette Emidecau Industries and CNRS Laboratories. The goal was to demonstrate composite parts to replace metals in aircraft structures that enable high production rates and can be cost competitive. The project also enabled characterization of the CF/PEKK material.

“We made the long omega stringers with six plies of Hexcel IM7/PEKK 190 grade material in our flat CCM machine,” says Leach. “Normally, you’d make it in a two-axis CCM, which is easier. But we have a way to make the omega shape in the flat CCM which reduces the cost and complexity of the tooling and equipment.”

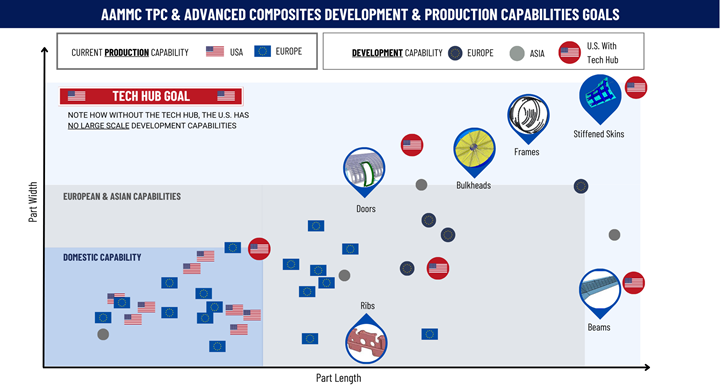

AAMMC tech hub for large TPC aerostructures

ATC Manufacturing is also a key partner in the American Aerospace Materials Manufacturing Center (AAMMC) which will advance the supply base for large TPC aerospace structures and and materials through technology readiness levels (TRL) 6-9. It will include a testbed and technology maturation facility for advanced composites housed in the previous Boeing-Triumph building in Spokane, Washington, owned by Lakeside Companies.

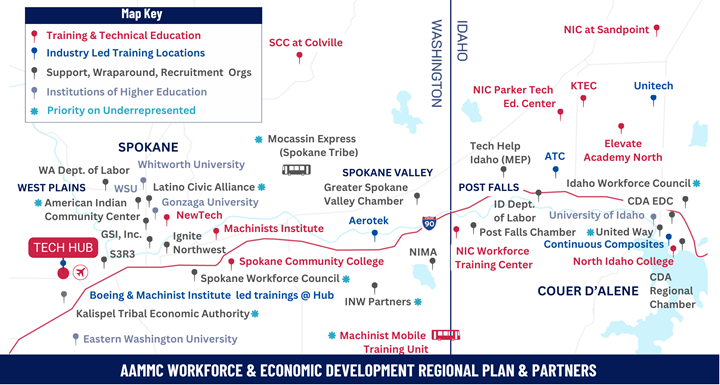

The AAMMC tech hub for large TPC aerostructures and materials goals (top), regional development map (center) and consortium partners (bottom). Source | Lakeside Companies

“We believe advancing thermoplastic and advanced composites to industry faster in the U.S. is critical for supply chain competitiveness and our domestic manufacturing base. In addition, these materials offer far faster cycle times for producing lightweight, high-strength parts. Industry cannot meet the current projected demand for aircraft and reach net-zero emission goals without significantly reducing cycle times and per-part costs for composite parts,” explains Maria Lusardi, marketing director for Lakeside Companies.

The AAMMC consortium includes companies and educational institutions from Spokane to Coeur D’Alene, Idaho. It aims to develop disruptive, high-rate production solutions for next-gen composite aerostructures and expedite the ability to meet NASA and aviation industry net-zero emission goals by 2050. One of 31 tech hubs established in October 2023 competing for $500 million from the federal Chips and Science Fund, the AAMMC submitted its Phase 2 proposal in February 2024, requesting $72 million from the EDA plus an $8 million industry commitment for a total of $80 million in funding for the first 5 years, after which it will be self-sufficient. “A large portion of the funding request is equipment,” says Lusardi, “including AFP [automated fiber placement] to produce TPC blanks, large presses for stamping, as well as machining and NDT [nondestructive testing] equipment. Winners of Phase 2 funding will be announced in the summer 2024 with funding given out in the fall. We are targeting 2 years to get all the equipment installed and commissioned. At the same time, we will begin ramping workforce training. This will include, for example, composites-focused machining apprenticeships. All consortium members have committed cash, workforce training, equipment, staff time, time on machines at their facilities or some other substantial contribution that benefits hub members. We see this Northwest Tech Hub as having a broad and vital impact across the region and the aviation industry as a whole.”

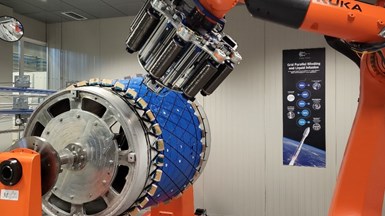

AI-assisted tool-less TPC welding

The German Aerospace Center (DLR) Institute of Structures and Design (Stuttgart and Augsburg) showed a video of its developments in tool-less AFP and jig-less welding of TPC structures using dual robots. Similar to the technology demonstrated in 2019 by General Atomics and Mikrosam, multi-robot cells are used to reduce the cost and time of jigs and molds and increase the design flexibility for composite aerostructures. The improved accuracy of the robotic platform uses AI-assisted geometric correction of the trajectories, as well as modeling, parameter identification and real-time compensation of the robots’ structural deformations during AFP and ultrasonic welding to produce complex-curved composite structures.

This development is also international, a collaboration between the National Research Council of Canada (NRC-AMTC, Montreal) and the DLR Center for Lightweight Production Technology (ZLP, Augsburg). ZLP is providing expertise in aircraft structural components, TPC production processes and automatic offline robot programming while NRC is contributing geometric and elastic calibration technologies and a real-time path compensation module for multi-robot systems.

C/C-SiC in rocket nozzles, piston rings and optical benches

DLR exhibited three different ceramic matrix composite (CMC) projects:

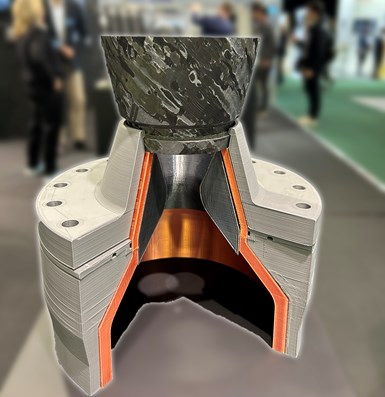

DLR has developed ceramic matrix composite (CMC) rocket nozzle extensions to reduce abrasion and weight for reusable launch vehicles. Source | CW

ATHEAt project (2022-2025) to increase reliability of critical high- temperature components for reusable launch vehicles and future space transportation systems. Components will be demonstrated through ground and flight tests. Using carbon fiber and a matrix of carbon and silicon carbide (C/C-SiC), a rocket nozzle extension was designed and produced for DLR’s Viserion+ hybrid engine. The aim is to increase nozzle efficiency by drastically reducing abrasion and component weight to enable reusability. Already confirmed in ground tests, flight tests on a sounding rocket are being prepared as part of qualification.

KoRSICa project (2018-2022) developed C/C-SiC piston rings to replace metal rings for higher temperature, more efficient engines for power generation. Monolithic ceramics withstand very high temperatures but are too brittle for one-piece piston rings. Fiber-reinforced CMC meet mechanical load and elasticity requirements with increased self-lubrication from the amorphous carbon in the matrix which protects against dry running and risk of piston seizure and engine damage. The rings are being tested with a local energy program.

This demonstrator of a lightweight CMC optical bench for a satellite is aimed to boost stiffness while minimizing thermal expansion for critical sensors. Source | DLR

European Space Agency (ESA) Technology Development Element (TDE) project “C/C-SiC Optical Bench Development” (2022-2024) with Thales Alenia Space, France (TAS-F). The goal is to develop ultra stable optical benches for satellites using CMC for high stiffness and near-zero thermal expansion. A generic demonstrator was manufactured (600 × 600 × 60 millimeters) including interface concepts based on in-situ joined C/C-SiC inserts to avoid even minimal local deformations possible with metal inserts. The demonstrator will be tested by TAS-F.

Largest melt-infiltrated C/SiC part

CIRA has developed this C/SiC CMC nose as part of the thermal protection system (TPS) for the ESA Space Rider, scheduled for first flight in 2025. Source | CW

Centro Italiano Ricerche Aerospaziali (Capua, Italy), or CIRA, displayed the CMC nose for the Space Rider, a reusable uncrewed robotic laboratory for commercial and institutional customers being developed by the ESA. About the same size as two minivans, the Space Rider is an end-to-end transport vehicle aimed to provide affordable and independent access to space. Space Rider will launch, stay in orbit for 1-2 months to complete scientific and commercial missions and then return to Earth.

The nose cone developed by CIRA was reported to be one of the largest melt- infiltrated CMC structures produced to date, according to a U.S. expert in the technology. The structure uses ISiComp, a proprietary CMC technology based on a carbon fiber-reinforced silicon carbide (SiC) matrix jointly developed by CIRA and Petroceramics (Stezzano, Bergamo, Italy). The ISiComp nose, belly tiles and body flap comprise the Space Rider’s thermal protection system (TPS). The nose starts as a carbon fiber-reinforced phenolic green body that is converted into a ceramic via pyrolysis, explains Giuseppe Rufolo, project lead for Space Rider at CIRA. “Petroceramics performs the pyrolysis and silicon melt infiltration. We tested this part in our SCIROCCO plasma wind tunnel [PWT] and confirmed its ability to withstand multiple re-entry conditions without any degradation. It was exposed to a high enthalpy hypersonic flow, producing a surface temperature of 1500°C, for six cycles of more than 14 minutes, each fully representative of a re-entry from LEO, with a record-breaking 90 minutes of total exposure.” The ISiComp nose, belly tiles and body flap produced by CIRA and Petroceramics are in the process of completing qualification testing, targeting the integration of flight units on the ESA Space Rider between the end of 2024 and beginning of 2025.

Since 2016, CIRA has developed fully integrated capabilities including design, novel materials, processes and testing of large CMC components for space applications. A first demonstrator was tested in SCIROCCO in 2018, followed by a full-scale Space Rider body flap in 2019, testing of a qualification model in 2020 and full-scale TPS nose in 2022, as described above. Felice De Nicola, head of Composite Prototyping Lab for CIRA, points out that SCIROCCO is the largest PWT facility in the world. “We also do vibration and thermal testing [shake and bake] and have a qualification lab dedicated for space parts.”

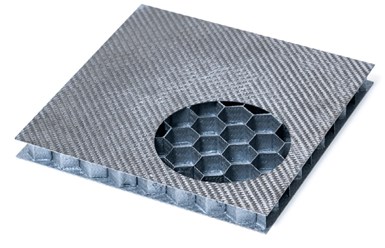

Dry fiber/infused anisogrids for Vega C and satellites

CIRA also displayed unique carbon fiber-reinforced thermoset polymer (CFRP) grid structures for space applications, including the interstage 2/3 for Avio’s (Colleferro, Italy) Vega C launcher, as well as a central body for a medium class satellite and deployable antenna boom and a cone adapter. In 2004, CIRA began manufacturing grid structures using wet and prepreg winding. By 2009, it had patented a “parallel winding” technique enabling a highly efficient and scalable method for creating anisogrid structures of interlaced helical and hoop ribs.

The Vega C launcher interstage was made with CIRA’s patented process that uses robotic winding to create helical ribs while a creel feeds tows to simultaneously interlace hoop rib. Source | CIRA

“We supported Avio’s production of the Vega C interstage and worked with them to mature the process in our lab,” says De Nicola. “Together, we developed the first prototypes at our facility. It took 2 weeks for us to wind the 2.4-meter diameter, 2-meter-long Vega interstage prototype. After successfully completing testing in 2018 — including compression loading up to 750 tons — Avio then produced the certification parts.” Vega C first flew in 2022 but missions were paused after the second launch, due to a failure in the nozzle of the Zefiro motor. Vega C is scheduled to resume flights later in 2024 with an intense program of launches for 2025.”

Composite anisogrid made using CIRA’s patented process interlaces helical and hoop ribs for inherent damage tolerance without buildups at the nodes. Source | CIRA

Branded by CIRA as “Grid parallel winding and liquid infusion,” the technique uses a robotic head to wind helical dry fiber tows while a creel simultaneously feeds tows for winding hoop ribs, so they are interlaced. Pins in the mandrel at the structure’s rims enable looping so that no fibers are cut. “We achieve a perfect cross-section in the laminates,” says De Nicola. “There is no distortion and no buildup at the nodes because we use dry fiber instead of prepreg.” These structures are also inherently damage tolerant. “We are able to integrate optical fibers into the lattice, as we did for a 1.4-meter-diameter conical adapter demonstrator, weighing 7 kilograms. This was tested at Israel Aerospace Industries to 80 tons. For these dry fiber anisogrid preforms, we also integrate interlaced CFRP flanges, window frames and local attachment points, and then co-infuse and co-cure the overall structure. We have successfully tested bearing of these local attachments with bolts through the ribs.”

Bespoke CMC in the U.K.

Exhibiting in the Startup Booster area of the show, High Temperature Material Systems (HTMS, Bristol, U.K.) was founded in 2021 to develop bespoke aluminum oxide matrix CMC materials that can withstand temperatures of 300-1000°C. Products developed to date include:

- KappaCera: A novel CMC material that possesses a low dielectric constant even in high-temperature environments, the result of integrating advanced fibers into HTMS’ state-of-the-art matrix system and optimizing the chemistry within the entire system.

- CarboniteX: Features high-strength carbon fibers into HTMS’ advanced matrix system, which expands the operational limits of carbon fiber-based systems far beyond current temperature capabilities.

- PhantomWeave: A multifunctional CMC system is designed to meet the complex requirements of the defense sector, combining low observable characteristics and high-temperature endurance.

- IgniShield: A low-density material made using woven basalt fiber with HTMS’ proprietary matrix, designed for fire/smoke/toxicity resistance applications spanning sectors such as automotive, aerospace and energy.

SiC fiber and CMC parts in Germany

BJS Ceramics and BJS Composites (Gersthofen, Germany) were founded in 2014 and 2015, respectively. BJS makes its own SiC fiber, branded Silafil, using a proprietary process. It also uses Silafil pre-ceramic polymer as a matrix to infiltrate carbon and SiC fiber reinforcements to create Keraman CMC materials and parts.

“We have an all-European supply chain,” says partner and co-founder Jutta Schull. “We are selling CMC parts into aviation engines as well as space and defense applications, where high strength and resistance to high temperature and thermal shock are needed. We offer build to print services as well as prototyping and small series production.”

BJS is developing a proprietary process to 3D print CMC parts using chopped SiC or carbon fibers in slurry. “We are working with short fibers and advancing toward very long fibers,” says Schull. The company is also developing its fibers to reinforce metal matrix composites (MMC), used, for example, to reduce weight in landing gear.

The companies are ramping up capacity. “We are seeing increased demand across the aerospace and defense sectors, but also from the energy industry, including nuclear fission and fusion, where cooling pumps cannot fail,” notes Schull. “This extends as well to pumps for water management in harsh conditions, such as in desalination (salt) and emergency pumps (mud, silt). CMC provides the ultimate durability, ensuring safety and continued operation for vital infrastructure.” She cites SiC/SiC pump bearing sleeves in serial production for 25 years.

Regarding the potential for CMC parts in nuclear energy, Schull notes, “CMC can be a game-changer. Due to their thermal resistance, high damage tolerance and radiation resistance, SiC/SiC components can double the electricity generation from fusion reactors — according to findings of our customers. These are, of course, long-term, yet very exciting development projects.”

For more information, see “NCC … to develop fusion-grade SiC/SiC composites” and read more about CMC temperature capabilities and growth in “A new era for ceramic matrix composites.”

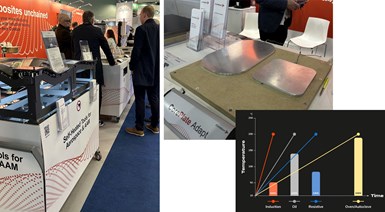

Induction heating industrialized for composites manufacturing

Corebon displayed heated shell tooling (left) and its range of heated plated products (CorePlate Adapt, top right) which provide three times faster heating than conventional composites processing technologies. Source | CW and Corebon

Corebon (Malmö, Sweden) has developed induction heating technology that is modular, highly adaptable and can be retrofit to existing production equipment to increae capacity. It enables very rapid and even heating that can eliminate long dwells, shortening cycle times by up to 80% resulting in energy savings of 50-80%. The company displayed its heated plate products, an induction welding setup and shell tool solutions, which may use the same power source and control equipment. Its heated plate products include:

- CorePlate All-In-One heated and cooled plate (500 × 500 millimeters) for integration into presses. Heating up to 275°C at 35°C/minute, cooling at 120°C/minute (3-4 times faster heating and cooling, respectively versus conventional methods). Multiple adjacent plates can be used for large part geometries and multi-cavity tools.

- CorePlate Adapt uses induction in the base to heat only where the mold is placed, up to 220°C at up to 50°C/minute. Custom sized to fit a variety of presses. Load plates into press and place molds onto each plate. Cooling can be provided upon request.

- CorePlate Tailor are designed for each geometry, ideal for high-volume production, enabling heating up to 220°C at up to 100°C/minute. Cooling is available upon request.

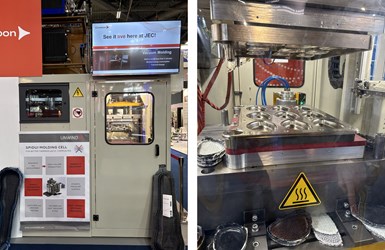

Unwind3D’s Spidui molding cell using Corebon induction heating (the CorePower equipment is in black view window above Spidui poster in left image) and a nine-cavity matched metal mold (right image) consolidating TFP preforms (bottom of right image) into glass and carbon fiber PA6 parts in <5 minutes. Source | CW

Unwind3D (Varese, Italy) is a spinoff from industrial embroidery machines supplier ZSK (Krefeld, Germany). Unwind3D works with clients worldwide to provide tailored solutions for the production of TPC parts which benefit from the use of tailored fiber placement (TFP) technology (made possible by ZSK equipment).

The company exhibited its Spidui molding cell using an induction-heated nine-cavity steel tool demonstrating fast compression molding cycles (< 5 minutes) of TPC preforms with a PA6 matrix. Corebon induction heating coils are in each cavity of both top and bottom molds. Cooling is achieved with water or air. The all-in-one software enables user-friendly operation.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

JEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More