Teijin Carbon Europe GmbH

Kasinostr. 19-21

Wuppertal, 42103 DE

+49 2452 97705-0

sales@teijincarbon.com

teijincarbon.com

About Teijin Carbon Europe GmbH

The manufacturer of TENAX carbon fibers (filament yarn and short fibers), with production facilities in Germany, Japan and the US. Also offers carbon fiber-based semi-finished products: TENAX ThermoPlastics, TENAX Part via Preform, TENAX Dry Reinforcements.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Teijin Carbon Europe GmbH Supplies the Following Products

- Carbon

- Carbon, Chopped strand

- Carbon, Milled fibers

- Carbon, Multiaxial

- Carbon, Other

- Carbon, PAN-based

- Carbon, Yarns

- Fabric

- Fibers, metallized

- Tape, unidirectional

Trade Names Offered by Teijin Carbon Europe GmbH

Editorial, News, and Products

-

Trends fueling the composites recycling movement

Various recycling methods are being considered for composites, from novel dismantling and processing, to building capacity and demonstrating secondary use applications.

-

CFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

Partners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.

-

Teijin Carbon Europe receives ISCC Plus certification

Certification covers Tenax carbon fiber production at Heinsberg-Oberbruch, Germany, plant, adds to Teijin’s certifications for carbon fiber and PAN in Japan.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

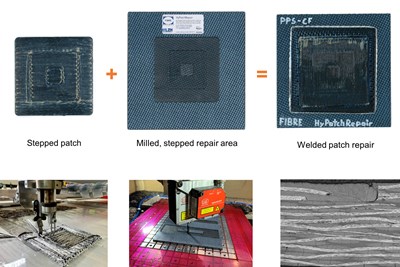

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Inside Teijin’s thermoplastic tape expansion

Teijin is qualifying its second thermoplastic tape line in Heinsberg, Germany, that will significantly expand the company’s presence in this material segment.

-

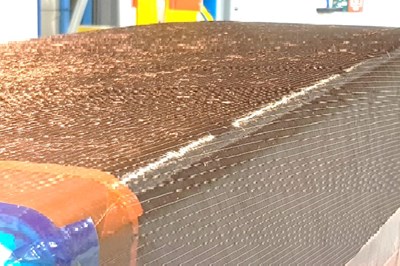

One-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

-

Teijin-supported Stedelijk Museum Amsterdam celebrates 10 years

The modern wing’s composite-paneled façade features Teijin Twaron para-aramid fiber and Tenax carbon fiber for a striking, seamless design.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

Henkel collaborates on study to reduce carbon footprint of aerocomposite parts

Led by Boeing Germany, research group aims to combine traditional manufacturing with digital tools to decrease part weight, optimize production efficiency.

-

Teijin Carbon Europe launches carbon fiber/PPS UD tape

The new Tenax prepregged tape with PPS matrix allows entry into new cost-sensitive markets while offering the typical TPUD advantages like resistance to chemicals and solvents, low flammability, storage or shipping at room temperature and recyclability.

-

Update: Lower wing skin, Wing of Tomorrow

Airbus is evaluating several advanced composites technologies as part of its Wing of Tomorrow program. Among these is liquid resin infusion of the lower wing skin, being developed by Spirit AeroSystems.

-

Teijin Carbon Europe, UK NCC strengthen carbon fiber partnership

As a Tier 2 partner, Teijin Carbon Europe plans to provide carbon fiber non-crimp fabrics, thermoset and thermoplastic prepreg materials.

-

High-rate, automated aerospace RTM line delivers next-gen spoilers

At Spirit AeroSystem’s Prestwick facility in Scotland, a glimpse of the future of aerocomposites manufacturing in a resin transfer molding line for A320 spoilers.

-

Teijin increases short carbon fiber capacity

Increased product capacity will enable the company to better react to European market demands and strengthen its carbon fiber portfolio.

-

German railway bridge suspended on CFRP hangers

The 72 CFRP hangers on the 127-meter-long railway bridge met installation, mass and sustainability goals.

-

CFRP preform technology is fast, flexible, efficient

Porsche racecar is first to sport part-via-preform technology.

-

Research project claims CFRP part production at half cost, faster throughput

The iComposite 4.0 project, led by Schuler AG and its partners, has tested its new production process with carbon fiber-reinforced plastic automotive prototype parts.

-

Teijin aramid, carbon fibers used for museum façade panels

The new wing of the Stedelijk Museum Amsterdam is the first and largest composite building constructed from Teijin’s Twaron and Tenax fibers.

-

Teijin supplies CFRTP for A350 XWB primary structural parts

The Airbus airliner incorporating Teijin’s Tenax TPCL carbon fiber thermoplastic consolidated laminate was delivered to Japan Airlines.

-

CFRP module saves weight on rocket design

Taking advantage of carbon fiber/PEEK mechanical and thermal performance, the Technical University of Munich replaces an aluminum rocket module with a 40+% lighter composite alternative.

-

University of MI Solar Car

The project was sponsored by Teijin, which supplied carbon fiber and aramid materials for the vehicle.

-

Teijin integrates carbon fiber business under one name

The Japanese parent company Toho Tenax Co. Ltd. has been integrated into Teijin Limited.

-

iComposite 4.0 — cutting composites cost by 50%

An intelligent, integrated process using 3D fiber spraying, inline inspections/simulation and embedded RFID chips to cut scrap and rejections for structural HP-RTM epoxy parts.

-

Consolidating thermoplastic composite aerostructures in place, Part 2

Thermoplastic composite structures could eliminate the autoclave and fasteners, but will a one- or two-step process prevail?

-

Toho Tenax hybrid prepreg combines carbon fiber, CNT

New high-tensile, highly shock-resistant prepreg incorporates carbon fiber developed for aerospace applications and specialized carbon nanotubes.

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Plant tour: Diamond Aircraft Austria, Wiener Neustadt, Austria

Composites use among general aviation manufacturers is far from unusual, but none apply them quite like this airframer does.

-

Composite chef’s knife a chef d’oeuvre

A while back I blogged about a luxurious version of a champagne flute, via carbon fiber and gold. The designer, Ragnar Friberg, is at it again, this time with a composite take on the chef’s knife.

-

Variable-axial composites open path to lighter composite structures

CFRP recurve bow riser demonstrates design and manufacturing approach with potential to cut weight vs. aluminum by 50-75% while increasing strength and stiffness.

-

Composites recycling: Gaining traction

Recycling of carbon fiber, glass fiber and — at last — resins, is growing as new players enter the space.

-

Supply and demand: Advanced fibers

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs

-

Toho Tenax develops production system for carbon fiber composites

The process combines Toho Tenax' Part via Preform technology with high-pressure resin transfer molding (HP-RTM) to speed manufacture of carbon fiber composites.

-

VBO prepreg on wing structure

GE Aviation scores first use of OOA wing trailing edge on large commercial aircraft.

-

Plant tour: Spirit AeroSystems: Prestwick, Scotland, UK

Global aerostructures giant Spirit AeroSystems ventures into out-of-autoclave (OAA) composites manufacturing via vacuum infusion.

-

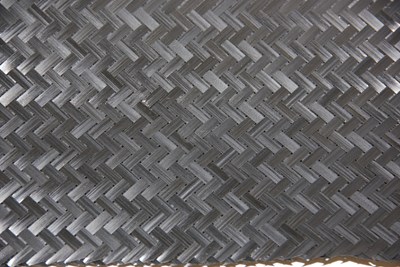

Automated preform process boosts properties and cuts cycle time

Fiber Patch Placement (FPP) achieves optimized fiber orientation for up to 150% increase in stiffness and reduced cycle time, weight and material waste.

-

Thermoplastic composites “clip” time, labor on small but crucial parts

Preconsolidated carbon fiber/PPS and PEEK and automated thermoforming enable six-figure production of connectors for the Airbus A350 XWB.

-

Yachtbuilding Composites: Rigged for Success

Carbon composite cabling in several forms races ahead of dry fibers and stainless steel in sailboat rigging.

-

Supply and demand: Advanced fibers (2015)

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs.

-

The matrix (2015)

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here's a guide to selection.

-

Articulated composite booms extend reach of concrete-pumping arms

A 25% weight reduction vs. legacy steel yields economics that justify upfront cost of carbon fiber.

-

CAMISMA’s car seat back: Hybrid composite for high volume

Recycled fibers, in-situ polymerized PA12 and steel inserts combined in one-shot process to cut weight 40 percent at competitive cost, cycle time and safety.

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Highlights: JEC Europe 2014

Composites enable high performance and lower weight in washtubs, wheelchairs and engine exhaust cones. Plus new, ultralight materials.

-

BMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

-

Structural preform technologies emerge from the shadows

Not yet in full production, with one exception, all are aimed at accelerating composite part manufacture at fast automotive rates.

-

JEC 2013 at first blush

CT Editor-in-chief Jeff Sloan risks some immediate reactions to his week in Paris at the JEC Europe 2013 composites trade show.

-

Market Outlook: Surplus in carbon fiber's future?

Participants at CW’s Carbon Fiber 2012 Conference see one coming as early as 2016.

-

An impec-able bike frame: Handmade by machine

Long on technology firsts, this optimized, automated manufacturing process produces nothing short of the “perfect” bike frame.

-

Big museum, big structures

Massive aramid/carbon composite sandwich panels make Amsterdam’s Stedelijk Museum the largest composite-clad building in the world.

-

Airbus A350 Update: BRaF & FPP

EADS Innovation Works pursues qualification of Braided Frames for the A350-1000 fuselage and develops Fiber Patch Preforming for complex local reinforcements.

-

SAMPE 2011 Long Beach Product Showcase

Huge show, huge new product offerings … huge success.

-

Mae West: Pipe dream in Munich

Unique fiber architecture and mandrel-less filament winding process make “impossible” rotational paraboloid sculpture possible in carbon composites.

-

Carbon fiber market: Cautious optimism

As the recession recedes, the demand for carbon fiber, and the supply to meet it, will exceed prerecession expectations.

-

2010 SAMPE Europe/JEC Paris Showcase

Record crowds and reignited technological development testified to the composite industry’s renewed health and the recent recession’s demise.

-

JEC Composites Show 2010 Highlights

Despite the volcanic ash that clouded air travel, an eruption of new technology and new business did much to dispel the clouds of economic recession.

-

Carbon Fiber: UP!

Despite 2008-2009 recession lows, prognosticators at CompositesWorld's recent Carbon Fiber Conference predict a decade of highs.

-

Carbon fiber reclamation: Going commercial

As the first commercial-scale carbon fiber recycling operations go online, research continues into both recycling alternatives and applications for recyclate.

-

JEC COMPOSITES 2009 Product Showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.