JEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Share

JEC World 2024 in Paris, France, gave the composites industry a chance to showcase hundreds of new products, services and applications. Among these included new sustainability-focused companies and products focused on recycling, bio-based composites and more. Source (All Images) | Hannah Mason, CW

JEC Group claims the 2024 JEC World trade show (Paris, France, March 5-7) was its largest ever, with 1,300 exhibitors and more than 43,500 visits from more than 100 countries, and more than 600 new products launched during the show.

CW’s editorial team was among those on the show floor, and is publishing a series of JEC World 2024 highlights covering some of the companies, trends and new technologies we came across.

Many of my conversations focused on “sustainability” solutions in composites manufacturing, including developments in natural fibers and bio-based resins and the growth of these technologies for applications in automotive and aerospace interiors; recycling (particularly a growing interest in glass fiber recycling); ways to measure carbon footprint such as life cycle assessments (LCA) and more. What follows are summaries of a few select highlights from JEC World 2024.

New products, players in recycling

This year’s trade show featured a variety of companies, both established and relatively new, presenting solutions for reuse or recycling of industrial scrap or end-of-life (EOL) composite parts.

On the newer side, Uplift360 (Luxembourg and Bristol, U.K.), started in 2021 with a new location in Luxembourg opened in 2023, exhibited its chemical-based solution for high-performance fabrics used in the defense industry, particularly unreinforced Kevlar or carbon fiber.

Hinde Boulbayem, director, explains that the company has developed two products so far: Renew is a chemical that can break down Kevlar and similar unreinforced high-performance fabrics “back down into a liquid form that can be reprocessed into high-quality material again”; ChemR is a chemical product for removing resin from carbon fiber composites.

“We provide a low-cost chemical solution for recreating these high-performance materials to reinject back into the fiber supply chain,” she notes. “We also have additional products in development for breaking down bio-based fabrics in future.” Right now, the company mainly serves the European market, but has plans to open a location in the U.S.

Sustainable solutions company Reprocover (Verviers, Belgium) was also at the show, featuring its services for collecting, mechanically breaking down, analyzing and reprocessing thermoset EOL composite parts into new, injection molded parts for the construction industry, such as gutters, manhole covers and more.

Catack-H displayed automotive components made from its latest recycled, milled carbon fiber product, and discussed plans for expansion and new recycling technologies in future.

Several companies acknowledged planned expansions of their current operations as their services continue to grow in demand. For example, Catack-H (Hwaseong, South Korea), founded in 2017 with a chemical-based process for reclaiming both fibers and resin from fully cured, epoxy-based carbon fiber waste, plans to expand into a larger, upgraded facility by the end of this year.

Catack-H collects carbon fiber scrap from both post-industrial and end-of-use sources (for example, Type 4 pressure vessels), uses its solvolysis process to reclaim both short and continuous carbon fibers, and then provides nonwoven mats, milled material or injection moldable pellets suitable for manufacture into applications like car components, electric vehicle (EV) battery applications, shoe insoles and more.

Swancor sells its EzCiclo recyclable epoxy resin for use in wind blades and other components. Broken down with its CleaVER recycling process, recycled carbon or glass fiber products can then be remanufactured into a variety of new components, including the pictured injection molded glass fiber car front bumper frame made with 30% recycled content (top photo) and a compression molded truck panel part made with recycled carbon fibers (bottom image).

Supplier of recycled glass fiber, recycled carbon fiber and resins Swancor (Nantou, Taiwan), which launched its EzCiclo recyclable epoxy and CleaVER solvolysis solution in 2022, is currently adding a third recycling facility to its operations. The company currently operates facilities in China (capacity of 150 tons/year now as phase 1, with a design capacity of 2,000 tons/year) and Taiwan (a demonstration line with capacity of 40 tons/year), and plans to open a larger facility in Europe next year. At these facilities, carbon and glass fiber composite waste is collected, fiber and oligomer are reclaimed via the CleaVER process, and fibers are remanufactured into products for reuse like carbon and glass fiber nonwoven mats, pellets and blended yarns for pultrusion. The EzCiclo recyclable epoxy resin is sold in resin form, or as a prepreg or towpreg.

James Tsai, international business unit sales director, says the company has an ambitious goal to sell only 100% recyclable or recycled materials by 2027.

These prototype carbon fiber composite bicycle pedals were made with Extracthive’s recycled materials.

Startup Extracthive (Laudun L’Ardoise, France) provided an update on its pilot-scale solvolysis process for reclaiming high-quality carbon fibers from high-value EOL parts like hydrogen tanks. According to Mehdi Mahmoudi, sales engineer, the company’s patented PHYre process enables up to 98% maintained mechanical properties in the reclaimed fiber, which the company then remanufactures into long carbon fibers (PHYre Dry), chopped carbon fibers (PHYre CSM) or “micro” carbon fibers (PHYre CMF) suitable for use in injection molding by compounders. “We’re currently seeking funding and partners and looking to scale up our operations,” Mahmoudi says.

Among its innovations and applications in carbon fiber pultrusion and pullwinding — including a growing business in pultruded cores for electrical cables and, notably, co-molded struts and connectors for the frame of the Flying Whale airship — Epsilon Composite (Gaillan, France) exhibited several parts on display made with recycled carbon fiber in partnership with Nova Carbon (Merignac, France), a company that realigns discontinuous, reclaimed carbons into semi-finished, long fiber products. “These materials exhibit up to 90% virgin properties,” explains Alexandre Lull, deputy CEO.

Glass fiber recycling

While higher value carbon fiber composites have generally been the top focus for fiber reclamation technologies, more companies are beginning to present solutions for reclaiming and reusing glass fiber as well.

For example, first-time exhibitor Infinici (Hamburg, Germany) is focused solely on producing nonwoven mats made with glass fiber offcuts. Founded in 2021, the company’s nonwovens are designed for use in resin transfer molding (RTM) targeting interior applications in automotive, marine and recreational vehicles.

Segvan Hasan, logistics manager, explains that Infinici nonwovens exhibit properties on par with traditional products, but with any recycled product, processing time may be a bit longer. “We use an in-house proprietary quality analysis process to make sure our products meet requirements and standards, and offer support to customers to learn the best way to process our materials.”

The ultimate goal is circularity, Hasan adds. “Our long-term goal is to get panels back after their use life, for reprocessing into new nonwovens.”

Startup Composite Recycling (Ecublens, Switzerland) is also focusing specifically on glass fiber recycling, and has developed a next-generation pyrolysis process and post-treatment technology for reclaiming high-quality glass fibers, as well as pyrolysis oils that can be reused for making new high-performance composites and plastics.

The company, founded in 2021, plans for its technology to meet companies where they are: Its pyrolysis reactor is designed to fit into 40-foot containers that can be transported directly to client sites via a mobile recycling truck.

According to project manager Victoire Radoux, the mobile units, which will start industrial-scale operations in Austria and western France, will be able to process up to 2 metric tonnes of waste per day. While developing these mobile units, the company is currently using smaller units to perform pyrolysis testing for clients that want to evaluate the recyclablity potential of their composite waste.

Other companies known for work processing carbon fiber composites are also beginning to work on solutions for glass fiber recycling. For example, Catack-H is working on technology for reclaiming glass fiber, according to Hendrik Neuhaus, director of global business development.

The newest focus for Owens Cornings’ sustainability roadmap is recyclability of its glass fibers and reuse in new products.

Fiberglass supplier Owens Corning (Toledo, Ohio, U.S.) is working on solutions in this area, launching a new phase of its sustainability platform focused on recycling solutions. The company has also announced sustainability goals for 100% renewable energy use and a 50% reduction in carbon emissions by 2030; recyclability is part of these goals. “As a company, Owens Corning is focused on recyclability from waste within our own operations, to waste created in the value chain, to waste at EOL of composite products,” says Paige Johnson, global product director.

Initiatives include taking back post-industrial waste from customers and, in a proprietary process developed by Owens Corning, reusing the waste in its Advantex glass fiber reinforcements.

“The next step will be to use different processes to reclaim glass fibers from EOL composite parts,” Johnson explains. Owens Corning has collaborated with several companies, including fiberglass-focused thermochemical process startup company Korec (Bientina, Italy).

Sustainability in automotive

Among automotive-focused suppliers I spoke with at the show, a key area of focus was “sustainability” within materials choices and operations to meet OEM goals and requirements.

For example, Teijin Automotive (Auburn Hills, Mich., U.S.) CEO Chris Twining spoke of the need for collaboration within the industry to meet growing needs for recyclability, use of recycled materials and reduced carbon emissions. He also said that Teijin Automotive is committed to reducing energy-intensive operations and switching some facilities like the company’s corporate headquarters to renewable energy.

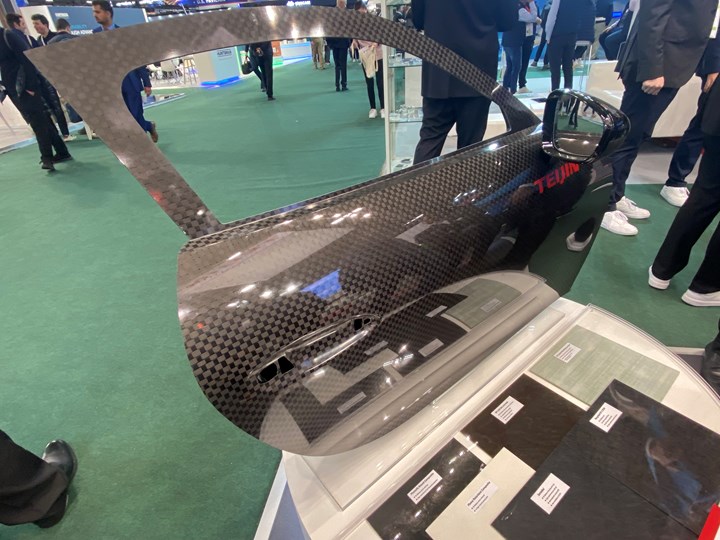

On display at Teijin Automotive’s booth was a prototype door design made in part with recycled carbon fiber veil from the company’s manufacturing scrap.

Alongside these efforts, Teijin Automotive is continuing to grow its Class A manufacturing capabilities in Europe and North America, as well as its capabilities for supplying materials, like its latest Hexacore honeycomb core and Foam-A-Core products.

The company was a finalist for a JEC Innovation Award for a 100% automated preforming process developed to make preforms for a carbon fiber composite, RTM’d door for customer Porsche.

Sustainable materials for battery enclosures

On the materials side, Mitsubishi Chemical Group (MCG, Tokyo, Japan) is expanding its focus into supplying materials for the manufacture of automotive battery enclosures for EVs.

“We really want to focus on the recyclability of battery boxes,” explains Marcel Remp, strategic growth manager for automotive/mobility. With partner EDAG Engineering (Groß-Zimmern, Germany), the company designed a prototype cover developed to meet standard crash and thermal runaway requirements. “The prototype represents a platform — we evaluated a variety of materials so that it can be tailored to meet OEM specifications.”

The battery box top cover can be made with Mitsubishi Chemical Group’s thermoset unidirectional (UD) prepregs, thermoplastic materials or the company’s BiOpreg PFA bio-based phenolic alternative.

Mitsubishi Chemical Group’s prototype battery box top cover is designed for easy assembly and compatibility with a range of the company’s materials.

“It’s designed for one-shot compression molding manufacture and easy assembly, and we’re looking into bio-based and even recycled materials,” Remp says.

Among the applications on display at Mitsubishi Chemical Group’s booth was an aerospace seatback prototype design made with the company’s bio-based phenolic alternative product.

Greg Jack, global business development manager, explains that the company has a focus on sustainability in all of the markets it serves, which includes aerospace, sporting goods, hydrogen storage tanks and ceramic matrix composites (CMC) for space applications.

Sheet molding compound (SMC) specialist IDI Composites (Noblesville, Ind., U.S.) introduced new research it had done with Forward Engineering GmbH (Munich, Germany) to evaluate the carbon footprint of its glass fiber SMC versus aluminum, steel, a glass fiber thermoplastic in a truck box design that was based on OEM specifications.

“It’s hard to compare the GWP [global warming potential] of different materials on a kilogram to kilogram basis. Differences in density, mechanical properties, and forming and assembly methods of different materials requires a system-level analysis to be meaningful,” explains Eric Haiss, global director of automotive business development.

With Forward Engineering, IDI set out to design a system-level LCA study evaluating all four materials and manufacturing processes for a variety of environmental footprint metrics, with the goal of transparency. IDI says it found that SMC had the lowest carbon footprint of the compared materials, and plans to publish peer-reviewed results later this year.

Natural fibers, for automotive, recreational vehicles and beyond

From the Mobility Planet to the Natural Fibers Village and elsewhere on the show floor, biocomposites such as natural fibers and bio-based resins continued to be demonstrated for a variety of applications, with automotive components a particular emphasis this year.

According to Julie Pariset, operation manager at the Alliance for European Flax-Linen & Hemp (Paris, France), “the automotive industry is really ready for production using these materials,” spurred by pressure from customers, OEMs or regulations to transition toward more sustainable materials.

Multiple natural fiber-based mobility components were on display at JEC World 2024, including flax fiber/bio-epoxy RV panels manufactured by Greenboats to demonstrate a simple-to-assemble, circular design (top image) and a vehicle body prototype displayed by Veso Concepts made with a mix of basalt fiber, flax and recycled carbon fiber (bottom image).

“There are opportunities for both structural and aesthetic parts, we’re seeing,” Pariset says. Examples include a flax fiber composite seat option for Polestar made by Bcomp Ltd. (Fribourg, Switzerland), on display in the Mobility Planet, and flax fiber/bio-based epoxy panels on the Greenlander “Sherpa” camper van (also on display in the Mobility Planet) built by Greenboats (Bremen, Germany) with Depestele (Valmartin, France) Lincore Roving flax.

There were also several other examples on display in the Mobility Planet at the show. One of these was an automotive bolster made from glass fiber/polypropylene organosheet overmolded with a natural fiber laminate, made by Valeo (Paris, France) with partners Bpreg Kompozit ve Tekstil A.S. (Nilüfer, Turkey) and W8SVR GmbH (Gescher, Germany). Sustainability-focused Veso Concept (Fontenilles, France) had on display vehicle bodywork developed with a combination of flax fiber, basalt fiber and recycled carbon fiber, with polymers reportedly formulated for lower temperature manufacturing, informed by LCA studies for the lowest energy consumption possible during manufacturing.

New this year, several Natural Fibers Village exhibitors such as Culture iN (Montaigu-Vendee, France) and Terre de Lin (Saint-Pierre-le-Viger, France) exhibited colored natural fiber fabrics designed for aesthetic automotive components.

For all end markets, the Alliance continues to conduct research and produce technical reports to aid manufacturers in the use of these materials. “As we move forward, we need to work on the industry’s EOL story, which will include more use of bio-based resins with these materials,” Pariset says.

Cobra International began commercial production this year of SMC automotive components, including some with natural fibers.

Cobra International (Chonburi, Thailand), among its other key end markets like watersports and drones, also emphasized its growing SMC production for automotive, including natural fiber SMC. “We did a lot of R&D to learn how to make flax work in these applications,” explains CEO Danu Chotikapanich. “The automotive industry is looking into natural fibers to replace carbon fibers in certain applications as part of their decarbonization efforts.”

Sporting goods: A glimpse of the Olympics

With the Olympics headed to Paris this summer, sporting goods were on full display, especially in a special Olympics-themed area at the entrance of the exhibit hall. Sports equipment could also be seen on display around the show floor.

Ahead of the Paris Olympics this year, a variety of composite sporting goods were on display, in a special Olympics area and around the show floor.

This carbon fiber and fiberglass composite iQFoil board design, developed by Cobra International and partner Starboard, will be used by Olympic athletes this summer.

For example, Cobra International showcased multiple pieces of equipment, including windsurf boards, a canoe and a carbon fiber composite surfboard — “these are gaining in popularity among athletes,” Chotikapanich says, for their ability to reach higher speeds and better springback compared to fiberglass boards. Notably, an IQFoil board on display at the booth represents a Cobra International design that will be used in this year’s Olympic games. Developed with manufacturing partner Starboard (Bangkok, Thailand), the boards are vacuum molded with precise layup of fiberglass and carbon fiber biaxial fabrics, wood and several foam cores, infused with epoxy from Sicomin (Châteauneuf-les-Martigues, France).

Sporting goods are also an area of interest for the vibration damping properties of many natural fibers, Pariset points out, and four pieces of equipment on display in the Olympics area featured natural fiber from Alliance members, she says.

Distributor Mel Composites prides itself on its technical support for customers. The company was able to help customer Karbon Design paddles cut its manufacturing time significantly for the production of these infused paddles.

Mel Composites (Barcelona, Spain), a first-time exhibitor at the show and distributor of custom foam, epoxy resins and consumables used in vacuum infusion, showcased padel rackets manufactured by customer Karbondesign (Barcelona). According to Eduardo Galofré, CEO of Mel Composites, the company, known for its history in naval architecture and technical support in infusion processes, was able to assist Karbondesign in adapting its process to reduce manufacturing time to a curing cycle of 10 minutes per batch.

Of course, these are only a few examples of the many technologies and applications on display at the show! For more, keep an eye out for CW editor-in-chief Scott Francis’ and CW senior technical editor Ginger Gardiners’ highlights, watch the on-the-floor videos posted on CW’s social media channels and follow along for more in-depth coverage of technologies from the show in the months to come.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

JEC announces three JEC Startup Booster 2024 winners

Out of the 20 startups, Zila BioWorks, TechnoCarbon Technologies and BioHalo were recognized for broader collaboration opportunities.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More.jpg;width=70;height=70;mode=crop)