Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Share

The importance of digital tools and simulation for successful composite parts design is well established, whether for aircraft wings, automotive bumper beams or bicycle frames. Over the past decade, these digital tools have extended into simulation and modeling of the processes as well, to explore materials-process interactions and address problems before production begins.

Today, most manufacturers use a variety of sensors to collect machine and process data (e.g., temperature, pressure, molding time) which can be fed into these simulations, but what if this modeling could be done in real time to adapt the molding process to each individual part?

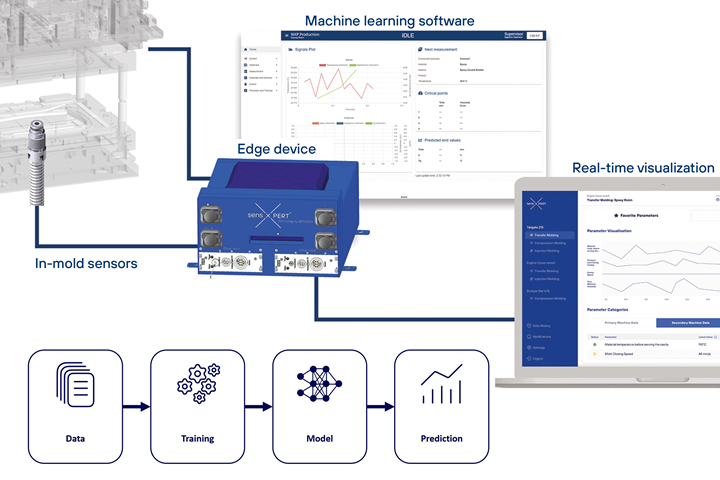

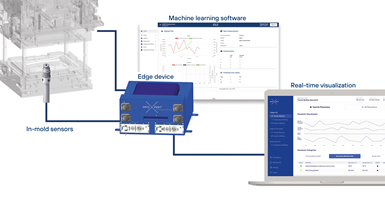

This is what the sensXPERT technology achieves, but instead of creating digital models, it collects machine and process data and combines it with data from dielectric analysis (DEA) sensor(s) in the mold that monitor viscosity and cure behavior in polymers and composites. It then applies data analytics via an edge device to let manufacturers see what’s actually going on inside the part — and control cycle times dynamically, for each part.

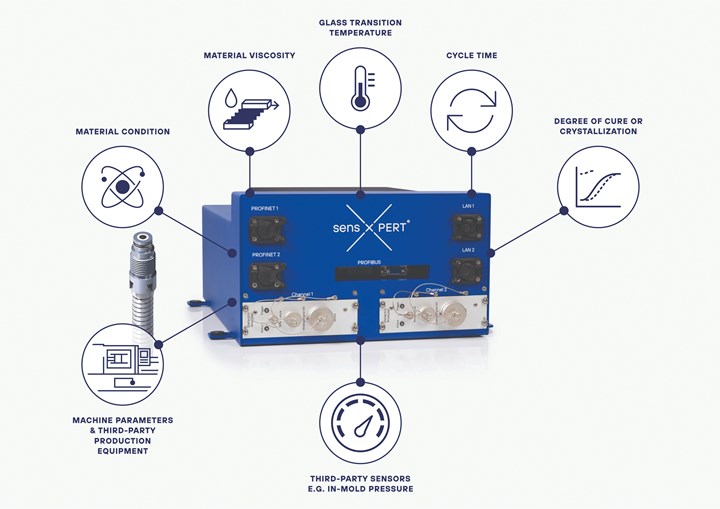

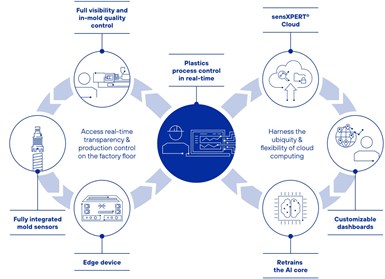

SensXPERT uses an edge device to collect data from its DEA sensors as well as third party sensors and then analyzes these data with software to track degree of cure/polymerization/crystallization, Tg, material viscosity and more (top), which helps to achieve a range of benefits that increase sustainability. Photo Credit: sensXPERT

This Digital Mold technology can be used in a wide variety of plastic and composite processes including injection molding, compression molding, resin infusion and resin transfer molding (RTM), as well as autoclave curing of prepreg. It enables manufacturers to stop the curing process, for example, when the desired degree of cure/polymerization or glass transition temperature (Tg) has been reached. It also enables tracking material viscosity and flow front position, as well as deviations in materials, helping to identify how to adapt processes to prevent scrapped parts.

By applying machine learning algorithms, sensXPERT can enable material behavior characterization in real time and adapting processes for improved quality control and dynamic cycle times. This then improves efficiency and reduces energy consumption, giving composites material suppliers and parts manufacturers a new tool to improve sustainability. For more details, watch the Sep. 28 webinar on CW.

History of sensXPERT: Netzsch buys DEA technology

The sensXPERT technology has been developed by Netzsch (Selb, Germany), a company founded in 1873 that developed into three divisions: Pumps & Systems, Grinding & Dispersing and Analyzing & Testing. In 2000, Netzsch bought Holometrix Micromet (Bedford, Mass., U.S.) and its DEA technology, which was spun off from MIT.

For years, the Netzsch Analyzing and Testing business unit developed and marketed the DEA technology for laboratory use. However, as digital technology began to advance, “the decision was made to move beyond the traditional business of lab-based thermal analysis, and out to the manufacturing environment in order to achieve real benefits in production,” says Alex Chaloupka, managing director of Netzsch Process Intelligence.

Chaloupka joined Netzsch Analyzing and Testing in 2016, where he worked for 2 years to advance the DEA sensor technology’s signal quality and ability to work with carbon fiber, which can create a short circuit because it’s electrically conductive. “And then in 2018, we decided to create a new business field within Netzsch Analyzing and Testing for process analytics,” he explains. “My job was to take our DEA technology into production applications around the globe and get feedback on what customers actually need. And while doing this, we doubled our revenue in both the first and second year of starting this new business.”

NedgeX incubator, data science, sensXPERT venture

“We then analyzed what our next step should be,” Chaloupka continues. “We had a good measurement technology and some customers who could analyze the dielectric data, but it wasn’t necessarily easy for them to translate that data into added value. We therefore decided that what we really needed was a new level of data science — a way to match material science from the lab with the production environment, to combine the information from the sensors with the machine parameters and the influencing factors that can affect the material behavior as the part is being produced.”

In 2019, Netzsch created NedgeX, a digital incubator company to work with its 4,600 employees globally and find teams with new ideas and business models for startups, as well as to support new developments and inventions at universities. “In 2019, I pitched the idea for sensXPERT along with NedgeX to our review board,” says Chaloupka. “It was like being in ‘Shark Tank’: Here’s how to use an existing measurement technology but equipped with new data science in order to combine sensors and material science for an entirely new product that really benefits the customer. This new venture was approved and we started as an incubator business in 2020.”

“Within one year, we created a minimum viable product comprising a new edge device and algorithms that can calculate quality parameters like Tg and degree of cure in real time and in a cloud environment that is connected to the device,” says Chaloupka. “Within our first year, we created awareness within large corporations.” The team also developed use cases with alpha customers ZF Friedrichshafen (ZF Group, Friedrichshafen, Germany) and Carbon Revolution (Geelong, Australia). “And we were able to show Netzsch shareholders that this is really a product that the industry values and needs,” notes Chaloupka. In 2021, Netzsch Process Intelligence was founded and sensXPERT was established as its first commercial technology product.

“So, we started with a small team of four people that were taken out of Netzsch Analyzing and Testing,” explains Chaloupka, “and now we’ve grown to 34 people. And this team can focus on our customers because services like manufacturing, shipping and accounting are outsourced to our sister businesses that already have that necessary structure, which is another benefit of operating within the Netzsch Group.”

Alpha customers and use cases

SensXPERT worked with ZF to analyze transfer molding of epoxy molding compound materials for EV control unit circuit boards (top left) using in-mold sensors (top right) to provide data on cycle time and material deviation (bottom). Photo Credit: ZF, sensXPERT

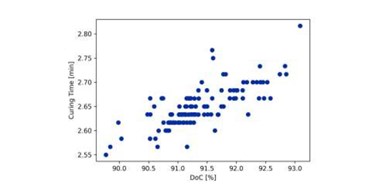

Chaloupka describes one of sensXPERT’s first customers, ZF Group: “It is one of the largest Tier 1 automotive suppliers producing metal and plastic components for the powertrain, such as electronic circuit boards for vehicle control units. We have written a technical paper with ZF about electronics encapsulation, which involves transfer molding processes with epoxy molding compounds. These materials are inhomogeneous and involve a tricky process for fast curing times of roughly 1.5 to 3 minutes.”

ZF was getting ready to start series production for an OEM’s next generation of electric motor control systems. “We looked at the material behavior within their manufacturing process and found potential for a cycle time reduction of around 21%,” says Chaloupka. “We could also see the material in the process was deviating, even when we worked with ZF to ensure all process and material parameters were the same for 100 parts in a row made using a single batch of material.”

Why is this a problem? “If we had followed the prescribed process recipe generated by the material supplier from their materials lab testing, we would supposedly have ended up with 100 good parts,” explains Chaloupka. “But what happens in reality is that every single part is different. To deal with this, material suppliers and molders add time onto cycles to give a kind of safety margin. But using our Digital Mold technology, we can eliminate these safety times by having a look into the material behavior and deviations that are affecting cure. And we can calculate the degree of cure and Tg in real time.”

SensXPERT is working with the aviation supply chain and various resin manufacturers to reduce cycle time for RTM and enable higher volume, faster parts manufacturing by using two-component resin systems for HP-RTM parts. Photo Credit: sensXPERT

Another alpha customer is an aircraft manufacturer, which is using sensXPERT technology in series production of carbon fiber/epoxy beams and panels. “After several years of working together, they have now completed a sensXPERT installation for RTM processes in a cascaded manufacturing line,” notes Chaloupka. “Here, we have identified a potential 30% reduction in cycle time. But there is also interest to apply this technology in different manufacturing environments, future development programs, where new materials are presenting new production challenges.”

Chaloupka notes that the aviation supply chain, “is looking at high-pressure RTM [HP-RTM] using two-part resins for cycle times of roughly 1.5 hours for really big structures, versus current cycles of 4-6 hours.” He adds that multiple resin companies have been working in this area, including Hexcel, Solvay and Westlake, looking at high-volume production of parts for future airplanes.

However, going from the current use of premixed RTM6 resin — which demands cold storage and has a limited shelf life — to long shelf life two-component (2K) systems that will be mixed just prior to resin injection in the RTM mold presents its own challenges (see “HP-RTM for serial production” and “2-part epoxy …”). Efforts continue to ensure mix ratios are correct throughout the injection and across the part. “We are working with CTC and an equipment manufacturer in a funded R&D project to implement sensors in the mixing heads to measure the mix ratio,” says Chaloupka. “The challenge is that operations within the mixing head are numerous and complex, such as turbulent flow, which affects measurement. We are analyzing how we can evaluate the mix ratio, what the precision is and how we can use this information to improve the manufacturing. We are also measuring the RTM’d part and directly relating that to mix ratio, and we’ve already seen trends. But we’re continuing this work with the parts manufacturers and the resin manufacturers, as there are still some open topics that need to be resolved.”

Basic components

SensXPERT uses in-mold DEA sensors, an edge device and software to convert the data from the DEA (and other) sensors plus the machine data into useful, actionable information. Photo Credit: sensXPERT

The sensXPERT technology has four basic components: sensors, an edge device, software and an IT framework for data analytics. “The DEA sensors are typically installed in the mold and create information about material behavior,” explains Chaloupka. “The edge device is a small industrial PC where the sensors are connected, receiving information from the material in the mold. The edge device is equipped with the dielectric measurement unit that can also connect to other sensors, such as pressure or temperature sensors from other companies. Thus, the customer can have just one edge device that is receiving an array of different signals/data streams. The edge device also communicates with the machine/molding control system so that we can exchange parameters and process data with the production machines. We not only receive machine data, but we can also send information back to the machine to initiate process actions or if a customer wants to see one of our signals directly on an HMI at the machine.”

“This industrial PC edge device is also equipped with software developed by sensXPERT, which includes machine learning algorithms,” he continues. “The system can perform a lot of analytics and machine learning model execution at the edge device, but enabling the machine learning training and retraining requires working in the cloud. For this, we need an IT infrastructure that we will verify together with the customer. And when the first data has been generated and the first parts manufactured, we will then create the machine learning models for the customer and use case, based on the material science and the real-time process information.”

How does the installation process work?

“A customer tells us they want to optimize a process,” explains Chaloupka. “We then discuss their challenges and long-term targets. Some customers want to reduce cycle times or scrap, while others just want to have transparency in the process to know what is happening and build knowledge around the parameters and material interrelations.”

“We then discuss their experience from their manufacturing environment,” he continues. “This is very important to develop the machine learning models so they aren’t focused in the wrong direction — not necessarily measuring every parameter but instead targeted to solve the customer’s challenge and provide real value. We create these machine learning models using material science that originated in the lab but that is now getting matched with real-time process information from sensors. And that lets us analyze how the material performs under different circumstances. We then combine that data with the machine data to bridge the gap between what we know from the original lab testing and what we see is actually happening with the material in the mold under different circumstances. This then allows us to relate all that information to each other.”

This, says Chaloupka, is the real value of sensXPERT because, “As humans, we are not really capable of taking 10 process parameters and relating them to the material behavior and to the material science in order to know that if I change this parameter, then this is what to expect. That’s just too much for our brains to do quickly, much less in real time.” There are some experts with decades of experience who can quickly assess manufacturing irregularities and adjust the right parameters, he adds. “But not every company has these experts and there are simply less of them around, which emphasizes the need for technology tools that can provide this type of assistance.”

Once the initial scope is finalized with the customer, sensXPERT then works with them to install the sensor(s), edge device and software/IT infrastructure. Parts are made and the machine learning models are built. “We then start the data analytics and evaluation process,” says Chaloupka.

Process transparency and optimization

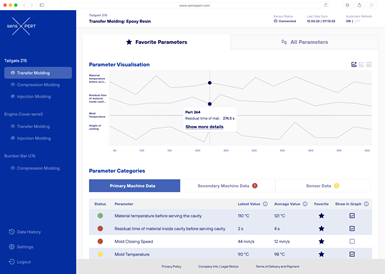

The sensXPERT edge device on the factory floor is connected to the customer’s intranet, giving them access to the system. Ideally, says Chaloupka, it is also connected to the internet, allowing data to be sent into a cloud environment for advanced analytics. “We have developed the necessary data security infrastructure and are accustomed to working with risk assessment frameworks for large corporations as well as providing the assistance necessary for smaller companies,” he adds. This final part of the installation is then completed working together with the customer.

“And then, from the edge device, we send all the data into a cloud environment,” he continues, “and our software uses the historic data to recalculate the machine learning models going forward, which will further enhance these models running on the edge device and increase the ability to identify areas for improvement. Meanwhile, the data is also fed into dashboards for everyday monitoring and operations.”

Use with thermoplastic composites?

Chaloupka says sensXPERT can work with a range of materials, including adhesives, coatings, preceramic polymers and thermoplastic composites. “We have grown within the thermoset resin market, and 95% of our existing customers are thermoset-oriented,” he concedes, “but we are reaching out to more and more thermoplastic customers. Yes, we can measure crystallization in semi-crystalline thermoplastics [e.g., PEEK, PEKK, PAEK] and also solidification in amorphous thermoplastics. We have a use case, but it is for in-situ polymerization of caprolactam into polyamide 6 [PA6] in Six Sigma product manufacturing. We have a series installation at a German company that is manufacturing volumetric semi-finished products where we have to optimize the manufacturing processes for different materials and with adapted chemistry (mixing ratio and additives) for different plate thicknesses.”

“We are also talking to companies working with thermoplastics who want to increase their recyclate content,” says Chaloupka. “Due to new EU regulations, there is no way for the plastics industry to avoid using more recycled content, even post-consumer material, which makes it harder to characterize every batch of material before you mold it. Therefore, new technologies are needed that can deal with material deviations and help to ensure proper manufacturing. Those deviations can happen from one batch to another, and you may need to change many different parameters in different directions to be able to produce good parts. We are looking into that because we can see and evaluate those deviations in real time.”

Further applications, collaboration with supply chain

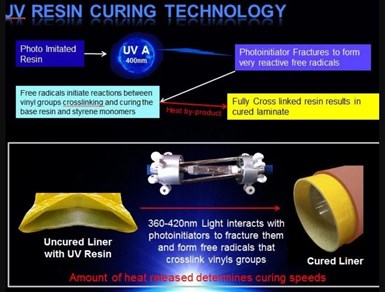

Cured in place pipe (CIPP) can use UV light to cure FRP pipe liners for trenchless repair without having to dig out old, corroded pipes. Photo Credit: Lightstream LP, “Cured in place pipe”, CW Dec 2012.

The company has already developed a second product, sensXPERT Pipe, for in-situ analysis of cured in place pipe (CIPP) liners made with glass fiber-reinforced polymer (GFRP). It uses touchless DEA sensors that are fitted to the robot carrying the ultraviolet (UV) light source through the pipe to cure the FRP liner. These sensors use radio frequency technology to provide non-contact cure analysis as the UV light is pulled through the pipe. “Now, you can see at what velocity the UV light should be moving,” says Chaloupka, “and, in real time, if there are deviations from the optimum degree of cure.” Again, dynamic processing is now possible — the speed of the light source can be modified on the fly. “And you have a built-in record of your quality assurance,” notes Chaloupka. “You are doing QA as part of the installation, not afterward.”

“Initially, our focus was to optimize plastic and composites processes for production,” says Corneila Beyer, CEO of sensXPERT, “and sustainability was a side effect. But now the demands of customers have changed. They are faced with making significant changes to meet new requirements for increased biocontent and/or recycling, as well as reduced energy usage. But they still need a stable process and assured quality for high-performance products. Our technology enables dynamic part production where they can optimize their processes in real time. But we go one step farther, using machine learning and AI to look across all of their parts and data to make predictions. For example, the system can send an alert saying the process is moving outside the allowed window and suggest adjusting X, Y and Z to bring it back in line.”

“And we are working with more than just parts manufacturers,” she continues, “because there is a whole supply chain involved, including machine manufacturers, raw material suppliers and toolmakers. We are already working with material suppliers, like Hexcel, to improve their products for their customers, and machine manufacturers like KrausMaffei and injection molding specialist Wittmann-Battenfeld . The momentum is changing for us to work with our part manufacturing customers and their suppliers in collaboration. The model is ‘better together,’ and we are beginning to see even the next developments this will enable.”

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

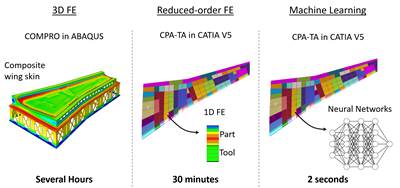

Using machine learning to accelerate composites processing simulation

A speed gain of 1,000 to 10,000 times greater than traditional FE models has been achieved using machine learning models, enabling near real-time simulation for large composite components.

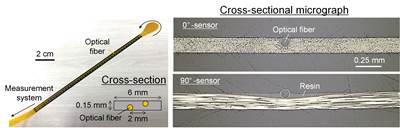

Read MoreMeasuring ply-wise deformation during consolidation using embedded sensors

Strip-type shape sensor method claims real-time measurement of ply-wise deformation.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More