Aciturri becomes investing and technology partner for Dovetail Electric

Partnership provides an opportunity to drive development of sustainable aviation via Dovetail’s upcoming hybrid electric aircraft, retrofitted with composite components.

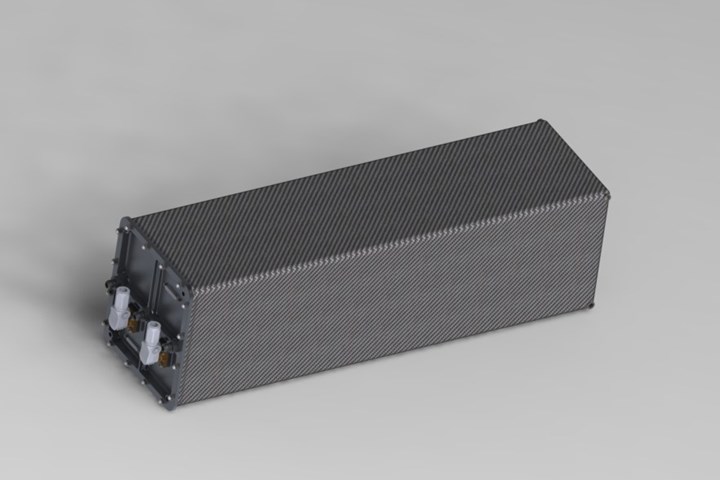

Composites will be incorporated into Dovetail’s retrofitted aircraft. One example is this custom-built battery module that Dovetail is developing. Source (All Images) | Dovetail Electric Aviation

Aerostructures supplier and engine components manufacturer Aciturri (Mirando de Ebro, Spain) has announced its commitment to acquire a stake in Dovetail Electric Aviation (New South Wales, Australia), becoming a key industrial strategic partner and lead investor in Dovetail’s seed investment round, Tranche 2.

“This partnership represents a significant opportunity to drive innovation in the aviation industry and broaden our contribution to a more sustainable future,” says Alvaro Fernandez Baragaño, CEO of Aciturri Aeroengines and chief diversification officer of the Aciturri group. “We look forward to working closely with Dovetail Electric Aviation to bring their groundbreaking technology to market.”

According to David Doral, CEO of Dovetail Electric Aviation, Aciturri’s involvement brings not only financial support but also significant capabilities that will enhance the company’s technology roadmap and accelerate its path to market.

Renders of a twin-engine Beechcraft King Air B200 that Dovetail owns and is using as a development platform for innovations such as composite air ducts.

Dovetail is initially targeting certification of its first battery-electric powered aircraft in 2026, as a first step to bring a product in the market. Later on, Dovetail will focus on the certification of electric-hydrogen aircraft conversions, with preliminary work currently underway with the integration of Dovetail’s first hydrogen-electric powertrain. The purpose behind an electric-hydrogen aircraft conversion for Dovetail is to extend the range of the battery-powered aircraft.

Doral tells CW that to achieve these goals, Dovetail is retrofitting existing aircraft. While this means the airframe stays the same, other areas will be available for composites use, including:

- Battery modules (see image above) developed in-house;

- Hydrogen tanks to be added when integrating hydrogen fuel cells;

- Specific aircraft add-ons, like cowlings or fairings required when slight modifications are performed over the original OML. A particular example are the air ducts required for extra cooling.

“There will be other opportunities we are jointly discussing, to be released in the future,” Doral says.

With this agreement Aciturri becomes the lead investor in the second tranche of Dovetail’s seed investment round. With a total target of $7 million, Dovetail split its seed round in two tranches, or parts, with the first one closed in 2023, with the airlines Rex in Australia, and Volotea and Air Nostrum in Europe, as the most relevant investors. In this second tranche, Aciturri is leading the round, to be closed shortly with the addition of at least one institutional venture capital fund

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.