Addcomposites AFPnext program grows digital automation capabilities for composites manufacturing

AFPnext aims to increase access to advanced composites manufacturing by eliminating key risks to manufacturers.

Share

Read Next

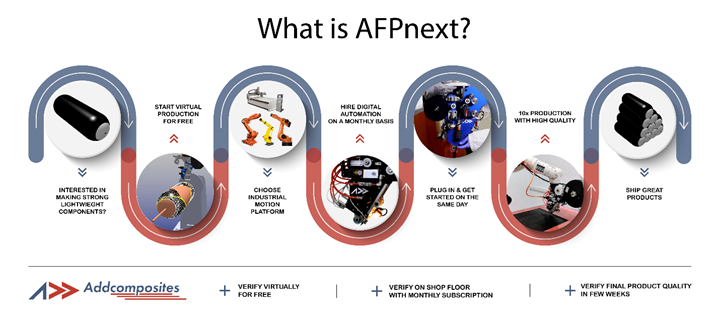

Addcomposites Oy (Espoo, Finland) introduces AFPnext, a new program with the fundamental goal of increasing access to advanced composites manufacturing by eliminating all the key risks to manufacturers. Addcomposites says the readily available automated fiber placement (AFP) system, which can be delivered within weeks, will provide SMEs with a high level of automation and connectivity at the scalability of 3D printers and the price point of hiring a new technician.

AFPnext is available to anyone who is interested or is already producing composite-related components and structures. Under this program, users are able to:

- Bid for high-value projects without needing a large upfront investment in equipment.

- Creates an ergonomic environment by automating otherwise strenuous layup tasks — either by direct part layup or creating preform kits.

- Work from home by doing all the engineering, planning, simulation, and virtual production runs with the included OLP software and IoT connectivity.

- Verification of whether automation is right for certain composite parts.

- Improvements upon existing production by optimizing selective/localized fiber placement: save material, save energy save the planet.

AFPnext applications. Photo Credit: Addcomposites

In order to take full advantage of AFPnext, the manufacturer must already have an industrial motion platform in place, in the form of either a CNC router or robotic arm. Addcomposites also offers customized industrial cells to suit any need.

“While it’s most beneficial to have a platform already in place, it is not necessary, as Addcomposites can supply industrial cells anywhere in the world,” says Pravin Luthada, CEO Addcomposites. Other, AFPnext includes everything to get started, including an AFP-XS head, OLP/simulation software, material for getting started, a helpful guide with video tutorials and more.

The AFPnext process involves the following steps:

- Find a part or component that you would want to:

- Improve quality and digitize documentation and tracking

- Optimize the design

- Improve profitability per part produced

- Produce larger quantity using less labor

- Convert existing metal/plastic components to lightweight strong components

- Work with the Addcomposites team to virtually simulate the production and determine the feasibility, amount of material used, the time to layup and any collisions/robot singularity for different configurations of materials and layup patterns

- Choose a motion platform in your facility for mounting the automation hardware

- Order the AFPnext package to your shopfloor

- Plug-in the ready solution and get started in less than a day

- Once implemented, production runs can begin

According to Addcomposites, users under this program can ship 10 times more parts, while also reducing manufacturing costs.

Contact info@addcomposites.com to get set up.

Related Content

-

STUNNING project completes lower half of MFFD

Clean Sky project has delivered the 8 × 4 meter welded aerostructure component, aided by advanced thermoplastic composite technologies and smart robotics.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Optimizing AFP for complex-cored CFRP fuselage

Automated process cuts emissions, waste and cost for lightweight RACER helicopter side shells.

.jpg;maxWidth=300;quality=90)