Alstom and Plastic Omnium design hydrogen storage for rail

Alstom and Plastic Omnium will cooperate to develop hydrogen onboard storage solutions for the railway market. This will reportedly enable direct journeys on non-electrified lines without using fossil fuels.

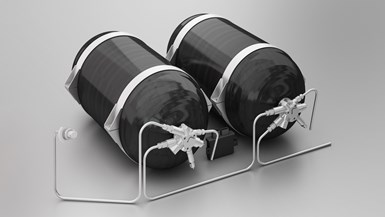

Alstom (Saint-Ouen, France), a leader in sustainable railway transportation, and Plastic Omnium (Levallois-Perret, France), a player in hydrogen mobility, have signed a memorandum of understanding to collaborate on the development of high-end hydrogen storage systems for the railway sector.

Alstom and Plastic Omnium will cooperate to develop hydrogen onboard storage solutions for the railway market. This will enable the two partners, following development projects which have already started, to launch hydrogen storage solutions on the market for regional trains in France and Italy, starting in 2022. This will reportedly enable direct journeys on non-electrified lines without using fossil fuels while meeting the challenges of sustainable development.

According to the partners, rail — as well as the truck, bus and commercial fleet sectors — is one of the first industries to develop zero-emission hydrogen mobility, opening up new growth prospects.

Christian Kopp CEO of Plastic Omnium’s Clean Energy Systems division, says, “Our partnership with Alstom aims to develop high-performance hydrogen solutions capable of tackling the sustainability challenges facing railway transportation. It is another step on the path toward carbon-free mobility.”

“The emergence of a strong hydrogen ecosystem is of critical importance for driving the development of hydrogen rail as a zero emissions alternative for regional rail,” says Thierry Best, chief commercial officer at Alstom.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

-

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.