AMRC, Tinsley Bridge develop metal-composite anti-roll bar for trucks and trains

Innovate UK project achieved 65% weight reduction via CFRP stabilizer bar and now tests for service performance and durability.

A team in the U.K. is working to advance lightweight composite anti-roll bars. Funded by the UK’s innovation agency, Innovate UK, the project pulls together engineers at Performance Engineered Solutions (PES) Ltd, the University of Sheffield Advanced Manufacturing Research Centre (AMRC) and Tinsley Bridge Ltd, one of the world’s leading suppliers of anti-roll bars for truck, rail and defense applications for customers including Volvo, Iveco, General Dynamics, Bombardier and BAE Systems.

The project is investigating the development and manufacture of lighter composite materials as an alternative to traditional metal anti-roll bars. Lightweight anti-roll bars could cut fuel consumption and emissions from rail and heavy road vehicles while also improving their reliability.

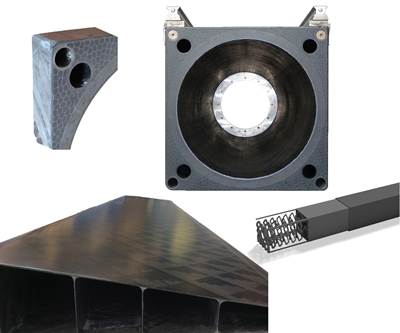

A previous Innovate UK-funded project achieved a 65% reduction in stabilizer bar weight by replacing the current solid steel component with a carbon fiber composite member. This weight reduction was achieved without compromising performance, and offers improved durability because carbon composite materials are more resistant to fatigue. The new project will further develop and refine the lightweight anti-roll bar design and complete a wide variety of laboratory testing to simulate real service-life conditions.

PES Performance is heading up the engineering and design side of the project, using its expertise in composites and lightweight materials the anti-roll bar design. The composite stabilizer bar prototypes are produced at the AMRC’s Composite Centre using its MF Tech filament winding system, in which glass or carbon fibers are impregnated with resin and wound onto a rotating mandrel to form the desired shape. It also used its CT scanner capability to inspect the inside of the bar, checking the structural integrity and verifying the build quality.

“ … application of composite materials in automotive and rail applications has the potential to form the basis of a new era of vehicles.” -Tinsley Bridge Ltd

“The targeted application of composite materials in automotive and rail applications has the potential to form the basis of a new era of vehicles,” said Russell Crow, project manager at Tinsley Bridge. “Significant weight reduction can be achieved by redesigning structural and safety-critical components to maximize their performance when manufactured from non-traditional materials.” He explains that the goal of this project is “to demonstrate what can be achieved on a heavy-duty anti-roll bar without compromising the safety of the vehicle. In order to deliver such a challenging brief, we built a strong consortium, comprising world experts in their respective fields.”

“Carbon fiber composites are commonly used in high-end supercars (read about IFA Rotorion’s CFRP anti-roll bar for the VW XL1), but have yet to see widespread use in the volume automotive sector,” added Dean Gardner, engineering director at PES Performance Ltd. “This project aims to show the wider benefits that these materials can provide. One of the major challenges has been to achieve a strong and durable interface between the materials in the hybrid anti-roll bars design, in order to achieve the required fatigue performance.”

“One of the major challenges has been to achieve a strong and durable interface between the materials in the hybrid anti-roll bars design ...”

“We are delighted to continue the project to further developing a new design for the hybrid anti-roll bar as the collaboration has the potential to develop a leading place for the UK with a disruptive technology that has global implications,” said Anthony Stevenson, technical lead for the AMRC Composite Centre, “one that will also have applications in other sectors including the aerospace and rail industries.”

Related Content

Thermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreRead Next

Filament winding, reinvented

Robots and digital technology deliver speed plus larger, more complex parts, while generative 3D winding obviates mandrels and waste for automotive applications.

Read MoreInnovating composites to open new markets

From machine tools to trainer jets, CompoTech develops new design and process solutions.

Read MoreHybrid carbon fiber/aluminum suspension knuckle

Yields 26% greater stiffness via bonded prepreg patch.

Read More