AMRC to add ultrasonic assisted machine tool

New composite machine tool will be the first of its size to be fitted with an ultrasonic-capable spindle for use in five-axis machining applications.

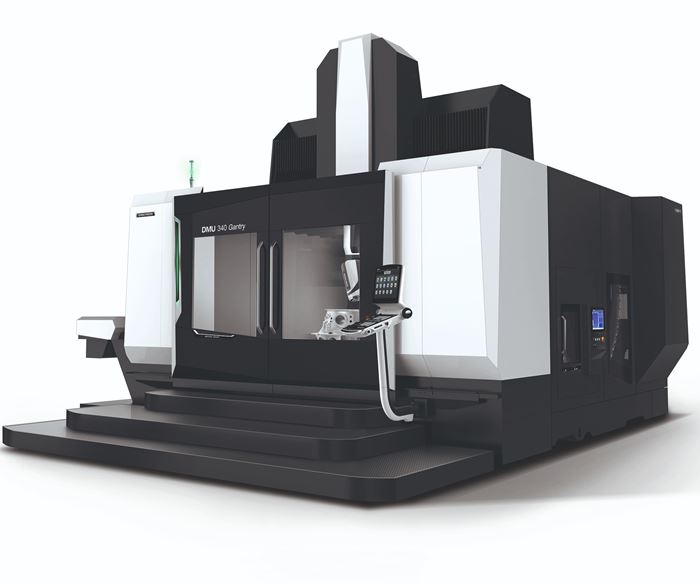

The world's largest ultrasonic assisted machine tool is coming to the University of Sheffield Advanced Manufacturing Research Centre (AMRC, Sheffield, UK). The £1.8m DMU 340 G linear machine tool arrives at the AMRC at the end of the year and will be the first of its size to be fitted with an ultrasonic-capable spindle for use in five-axis machining applications.

The specification for the machine – which has a 59 m2 footprint – has been tailored and developed by DMG Mori (Bielefeld, Germany) with the input of Dr. Kevin Kerrigan, the lead for the Composites Machining Group at the AMRC Composites Centre.

The DMU 340 G is capable of providing significant improvements in composite machining, ranging from high-end luxury vehicle monocells to next-generation aeroengine lightweight fan blades. It is also capable of titanium drilling and finishing operations and working with materials of the future such as glass fiber reinforced aluminium, a glass fiber in a resin laminate interspersed with sheets of aluminium and an array of high-temperature composite materials.

Other features of the machine are said to include linear motors for high accuracy and rapid motion, dust extraction technology, high pressure cutting fluid delivery systems, on machine inspection technology, and industry 4.0 capabilities including wireless in-process monitoring and control technologies, enhanced connectivity and plug-in technologies to interface with the AMRC’s data analytics suite.

According to AMRC, the advantage of the machine’s ultrasonic capabilities is that the high frequency movements – 40,000 micro-movements per second – bring a higher degree of control of chip formation and heat within the system. The result, claims the AMRC, is less damage, less waste and a better finish, making the technology well-suited to machining hard, abrasive, brittle material like carbon fiber composites, alloys and CMCs.

According to Kerrigan,

“The ultrasonic assisted machining process is basically the same as a standard rotatory cutting tool operation, but with an added highly tuneable, micro-scale, axial motion of the cutting tool providing a secondary motion during cutting.

“It is the additional movement that has the ability to control the amount of energy supplied into the cutting interface affecting the amount of thermal energy and fracture energy associated with the process.

“The incoming machine also has linear drives which create better acceleration and change of acceleration, i.e. jerk, to push the machine really fast during 5-axis tool paths which helps when producing complex shapes at high rate whilst retaining part geometric accuracy. With this linear drive system, the machine can get up to feed rates of 90 m/min. Current feed rates, between 1 and 4 m/min, are mostly driven by the fact that the forces generated during cutting, even with rpms of over 20,000 rpm, would snap the tools if feed rates got any faster. That is a massive difference and a huge benefit to productivity.”

The machine is digital ready – kitted out with an intelligent, customizable controller that allows the machine to integrate process-monitoring techniques, providing data that can not only measure performance but also help to improve tool life.

“The usefulness of this is really on the process monitoring side of things. The 840D controller is considered state-of-the-art for enabling the extraction of process information, enabling machine health monitoring, shop floor connectivity and closed-loop adaptive control,” says Kerrigan, “It can also link to additional live retrofit process measurements that are linked to things like tool wear, damage defects on a part. That’s useful information that gives us greater insight into the machining operations being undertaken on complex materials.”

A fundamental part of the Composites Centre’s work into machining research is measuring cutting forces and temperature as these provide a wealth of information about the health of the process, such as whether a process is dynamically stable, if there is any chatter or forced vibration, the rate of tool wear and whether a machine is being driven beyond its capabilities or experiencing mechanical/bearing wear.

“For carbon fibre-based composite materials, because it’s a highly abrasive process – even with diamond as the cutting tool which is commonplace in industry – you have to replace your tool very regularly to the point where between 50 and 60 percent of the whole process cost comes from cutting tools,” Kerrigan adds, “The proposed data that will be extracted from this machine can be used by artificial intelligence platforms, such as IBM Watson, to learn how to stretch the life of a tool without interrupting the process.”

The machine is reportedly able to operate in both dry and wet machining configurations – without harm to machine moving parts, electronics or operator – and can work on a range of materials from titanium to polymer composite and has high productivity through rapid traverse rates. It also has particle controlled door opening, an infrared measuring probe and the tool changer introduces DMG’s novel modular carousel design.

The DMU 340 G linear is due to arrive at the AMRC in late December.

Related Content

Bio-based SiC ceramics from wood polymer composites

Austrian research institute Wood K plus makes 95% silicon carbide ceramics more sustainable (>85% bio/recycled content), enables 3D shapes via extrusion, injection molding and 3D printing.

Read MoreSRI advances CMC for solar, renewable energy and industry

U.S. research institute advances “infiltration-free” process for improved performance, durability and affordability of materials able to withstand highly corrosive environments at temperatures beyond 700°C.

Read MoreBombardier begins manufacture of Global 8000 business jet

Ultra-long range business jet featuring CMC-intensive engine and a range of 8,000 nautical miles is set to enter service in second half of 2025 as it remains on track for flight testing.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More