AniForm, Moldex3D develop interface tool for more accurate RTM prediction analysis

Interface enables users to consider forming-induced fiber reorientation in the RTM simulation model for a more accurate representation of the flow domain.

All photo credit: AniForm, Moldex3D

AniForm Engineering (Enschede, Netherlands), an advanced simulation tool that predicts the formability of composite laminates, is collaborating with Moldex3D (St. Zhubei City, Taiwan) to enable users to run more accurate resin transfer molding (RTM) analyses. With this new interface, workflow has been improved to smoothly import the fiber reorientation data (recorded as an ASCII file) from AniForm Suite and run the RTM simulation with Moldex3D’s simulation tools. Additionly, input accuracy for the RTM model has been optimized and RTM simulation results made more accurate.

“AniForm strives to deliver a software tool that enables engineers to focus on the analysis of a prediction, rather than spending too much time on modeling and data transfer between various simulation tools,” says Sebastiaan Haanappel, managing director at AniForm. “Moldex3D is a renowned partner in the industry, so we were thrilled to cooperate with them. We were very happy with this collaborative effort, which led to a seamless interface between our tools.”

When coming up with the solution, both AniForm and Moldex3D focused on targeting the following challenges:

- Lack of a seamless workflow between the different simulation tools;

- The fiber orientations in a fabric change significantly during forming;

- Fabric shear and fiber reorientation locally affects the magnitude and orientation of the fabric’s permeability property.

To address these, a case study was performed, with the main objective to compare the different results between two models; one that directly assigned an assumed orthogonal fabric orientation, and one that considered the fabric orientation result from an AniForm forming prediction. The goal was to see how different inputs can have a significant impact on the resin infusion simulation results.

First, AniForm’s team generated a simulation of a woven fabric forming that was then used as an input in Moldex3D software for the fabric orientation. The fabric simulation was exported as an ASCII file from AniForm and imported in Moldex3D to run the RTM simulation.

Then, the part was created. A laminate consisting of five fabric layers with a [(0/90)]5 layup was formed into a mold cavity, which represents the final part shape. Subsequently, the mold itself was heated and injected with resin, with a final part released after curing. This part was referred to as the Formed Woven Fabric (Fig. 2).

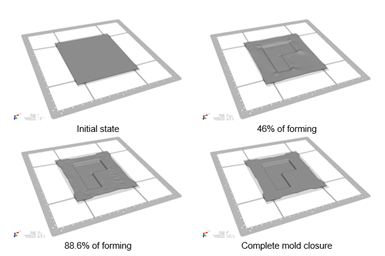

Fig. 3. AniForm forming predictions at various instances.

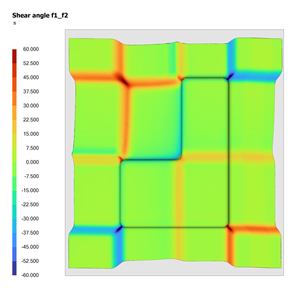

To take into consideration the forming induced fabric distortions in a subsequent infusion simulation in Moldex3D, a composite forming simulation in AniForm was performed. Fig. 3 shows the predicted laminate deformations at various instances during the forming. These deformations led to the resulting in-plane shear distribution and related fiber re-orientation at complete mold closure in the final step as shown in Fig 4.

Fig. 4. Shear angle distribution predicted by AniForm.

Two infusions model configurations were created in Moldex3D (see Fig. 5). The first model assumes the fabric still to be orthogonal, namely 0º and 90º in every part (light blue: 0º, dark blue: 90º). However, Moldex3D and AniForm note that, in reality, an orthogonal fiber orientation will not be present since the forming leads to in-plane fabric deformation, meaning the fabric orientation will no longer be 0º and 90 in every part. Therefore, the second model considers the forming results from AniForm, using the forming induced fiber-reorientation. Because the fiber reorientation affects permeability (indicated in Fig. 6), Moldex3D and AniForm believe the second model to result in a more accurate representation.

Fig. 5. Fabric orientation.

Fig. 6. Flow front.

Thus, the case study concluded that the developed interface, improving the estimation of the flow progression over time, enables engineers to better anticipate changes in the process configuration and production cycle durations, as well as a higher degree of confidence when analyzing and interpreting the results.

“We are delighted to cooperate with AniForm, which is undoubtedly a remarkable player in our industry,” says Dannick Teng, managing director at Moldex3D. “This is the first step of Moldex3D and AniForm’s collaboration, and we are both looking forward to further integration soon.”

For more information, please contact support.eu@moldex3d.com or info@aniform.com

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)