Caracol inaugurates tech assembly, innovation facilities in Milan

Caracol continues to evolve large-format additive manufacturing, opening two additional state-of-the-art facilities to accommodate client services, as well as materials and processes R&D.

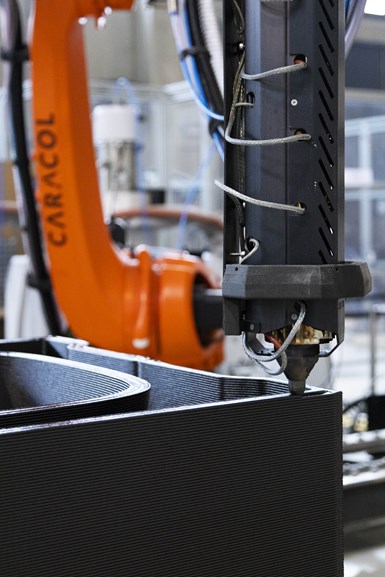

Large-format additive manufacturer (LFAM) company Caracol (Milan, Italy) has officially opened the doors of a new Technology Assembly facility and Innovation Hub near Milan. The company says that it is always pursuing its vision to expand the adoption of LFAM technology for more efficient, flexible and sustainable production means for industrial manufacturing.

Caracol has scaled up internationally, creating a strong multidisciplinary team globally. The company has invested on developing technology and a service-first approach — this led to the opening of its latest facilities near Milan, Italy, together with the revamping of its state-of-the-art, ISO 9100-certified, LFAM production plant and the opening of its North American headquarters in Austin, Texas, last year. Caracol now has four global facilities — and is expecting to open a new office for the GCC area in Dubai, as well.

This month, Caracol has inaugurated two facilities. The first is a new Technology Assembly and Testing facility, where the company’s Heron AM platforms will be developed and tested, customized to fit client specifications and manufacturing needs. The team at this facility will work closely to support clients in designing and preparing their shop floor space for equipment installation.

There is also the Innovation Hub, a facility designed to accommodate the company’s R&D team. Here, different labs are dedicated to developing the integrated technologies and processes Caracol provides, including materials testing and qualification, software, hardware and automation, and polymers and metals.

“Our work is centered around the needs our customers have in manufacturing parts and applications,” says Paolo Cassis, COO and co-founder of Caracol. “Opening these facilities will allow us to further grow on delivering top quality, reliable, technological solutions made for production.”

To celebrate this milestone, Caracol hosted an official opening event on Feb. 1, 2024. Attendance included partners, customers, institutions and industrial manufacturing leaders.

Related Content

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

.jpg;maxWidth=300;quality=90)