Global consortium to bring high-value LFAM to the U.K.

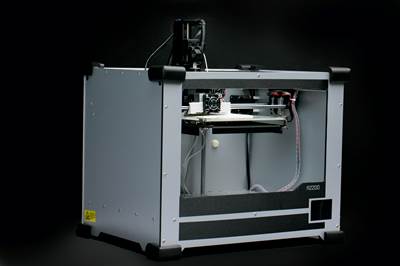

The Evo One LFAM project will develop and commercialize a more supportive AM platform, which will include continuous fiber capabilities in the future, to increase accessibility for U.K. companies.

Advanced additive manufacturing (AM) technology being developed by a global consortium of companies and academic institutes aims advance industrial AM in the U.K. The Evo One large-format additive manufacturing (LFAM) project — involving 3D printing experts Evo-3D (Exeter, U.K.); the National Manufacturing Institute Scotland (NMIS) operated by the University of Strathclyde and part of the High Value Manufacturing Catapult; Rolls-Royce (London); materials supplier Filamentive (Bradford, U.K.); software developer AI Build (London); and energy technology company Baker Hughes — are developing a 3D printer system. The initiative has received £1.1 million in funding from Innovate UK, the U.K.’s innovation agency.

LFAM is a commercial 3D printing technique that creates large-volume polymer components, used in a variety of industries including aerospace, automotive, energy and marine. While countries like the U.S., Germany and China have embraced this approach, there are currently no LFAM manufacturers in the U.K., and, according to Ayming, the country only accounts for around 5% of the global AM market, which the U.K. government aims to increase to 8% by 2025.

Access to the right technologies will be a crucial part of achieving that aim, but existing LFAM systems have their limitations. These include slow build times, being unsuitable for high-value or high-integrity parts, operational complexity, use of unsustainable materials and being unaffordable to small- and medium-sized companies.

At the project’s completion, Evo-3D will launch a spinout business to commercialize the system, called RapidFusion.

“We saw during the pandemic how easily supply chains can crumble,” Jake Hand, director of marketing and development at Evo-3D, says. “That’s why it’s potentially more important than it ever has been to develop as much capacity and capability in the U.K. as we can, not to mention the economic and carbon reduction opportunities associated with having a thriving manufacturing sector at the vanguard of the latest available green technologies.”

The new product being developed through Evo One LFAM will address the challenges associated with these systems and cater to the specific needs of the U.K. market. The system’s design team is aiming to make it 60% more reliable, achieve a 50% increase in productivity, reduce training and maintenance costs by 30%, and cut material waste by 80%, among a range of other improvements. It was noted that while fiber reinforcement will not be offered during initial product launch, due to the modular nature of the machine, there will be a continuous fiber module available in the future to purchase.

At the project’s completion, Evo-3D will launch a spinout business to commercialize the system, called RapidFusion, creating what is said will be the first U.K.’s OEM in LFAM. Its development would also create the foundation on which a new supply chain can be built, reshore critical manufacturing capabilities and help more U.K. manufacturers take advantage of the opportunities presented by Industry 4.0.

The NMIS team will support the project across a number of specializations, including material analysis, design and the AM process. It will also look at the validation and verification of the system and high-value materials being used. Rolls-Royce and Baker Hughes will test the system once it is ready, while AI Build will help with development of the slicing technology.

“With the right tools at our disposal, we can encourage more manufacturers of all sizes to embrace the latest manufacturing techniques and technologies, paving the way for a more sustainable and globally competitive sector,” Stephen Fitzpatrick, director – digital factory at NMIS, says.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

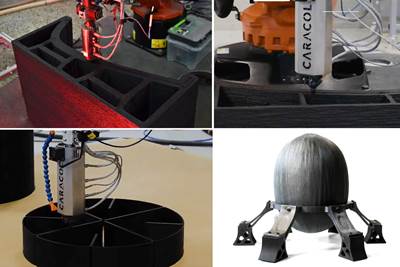

Caracol AM launches new identity, celebrates composites applications

Italian supplier of Heron large format additive manufacturing (LFAM) technology showcases circular economy and aerospace applications.

Read MoreNano3Dprint expands 3D printer distribution to Taiwan

Distribution of multi-material printer using chopped carbon fiber and a dual-dispensing printer in Asia is led by second partner Collimage International.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More