Carbon fiber prepreg monocoque masterclass launches September 15

First out of two live session masterclasses offered under The Native Lab’s Composite Materials training course is taking place Sept. 15 at 6 p.m. CET (12 p.m. EST).

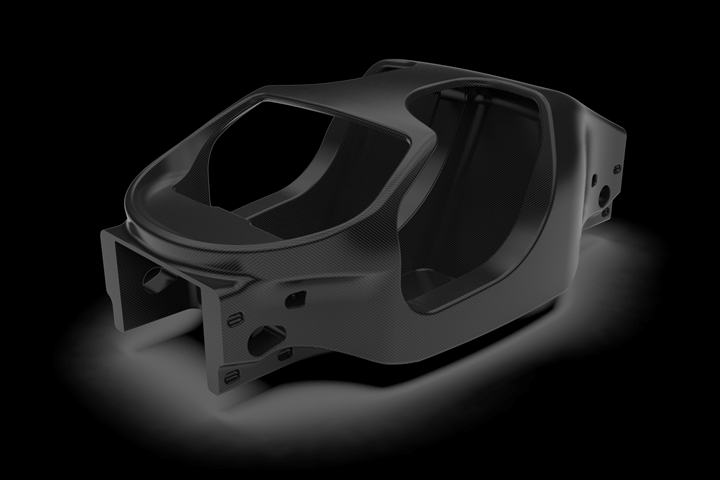

Photo Credit: The Native Lab

In July 2022, The Native Lab (TNL, Madrid, Spain), Managing Composites’ training division, announced the addition of online sessions to its self-paced Composite Materials training course (learn more). One out of two of these online live sessions, a masterclass on manufacturing a carbon fiber prepreg monocoque, is taking place Thursday, Sept. 15, 2022 at 6 p.m. CET (12 p.m. EST).

Together, participants and the primary course trainer — Eneko Angulo, now chief operations officer (COO) of Managing Composites — will learn how to manufacture a carbon fiber prepreg monocoque, taking into account things like cosmetics, overlaps, width of roll, B-surface and sandwich construction. Angulo has previous experience from McLaren Automotive (Woking, U.K.) and Koenigsegg Automotive AB (Ängelholm, Sweden).

More than 100 people have already joined the composite materials course and will be joining the masterclass. By enrolling now participants will have access to this live session as well as all course materials. For more information visit the course syllabus page.

Also learn more about a new course offered on monocoque structural analysis here.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.