Cincinnati Inc. BAAM printer demonstrates 3D printing with recycled composites

Dual-material thermoplastic extrusion system produces monolithic composites tool exceeding 10 feet in length, without manual intervention.

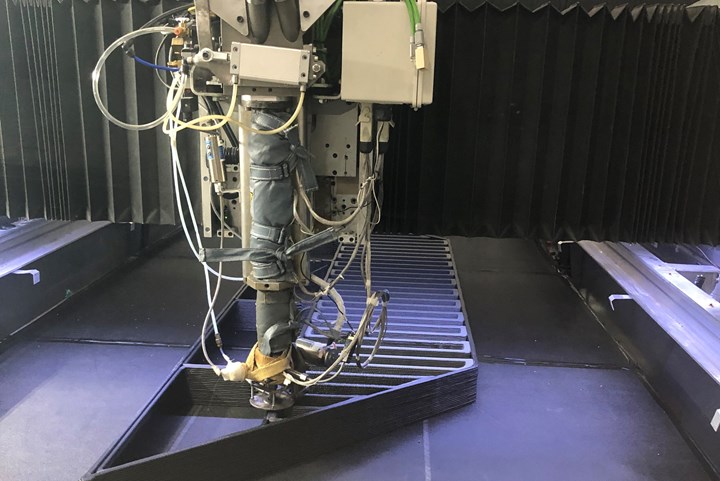

BAAM multi-material extrusion system. All photo credit: Cincinnati Inc.

Cincinnati Inc. (CI, Harrison, Ohio, U.S.) announced that it has used its Big Area Additive Manufacturing (BAAM) machine to demonstrate that recycled materials can be used for 3D printing by producing what the company says is one of the largest monolithic multi-material objects to date. The demonstration successfully proved that large-scale multi-material printing can be done effectively and economically with recycled composite materials.

The large-scale multi-material print was achieved by making modifications to the BAAM and including a new extruder design that accommodates a dual feed system.

For the past several years, CI has collaborated with the U.S. Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL, Knoxville, Tenn., U.S.) to continuously improve and develop the BAAM. Initial research focused on large-scale printing of single material systems, typically short fiber-reinforced polymers.

The large dual-material thermoplastic extrusion system reportedly enables the user to print with multiple different materials within a single build using just one extruder.

“The objective of this particular study was to demonstrate printing of a multi-material composites tool including transitions, exceeding 10 feet in length, containing recycled material and printed without manual intervention,” says Alex Riestenberg, CI’s Additive Manufacturing product manager.

The part selected for this demonstration was a single facet of a precast concrete tool used in the production of commercial window panels for a high-rise development in New York City. The mold weighed approximately 400 pounds, with a length of 10 feet, 10 inches. Print time was approximately seven hours.

“Studies have shown that by using multiple materials within a structure, new mechanical responses and multi-functionality can be achieved — such as lightweight structures with tailored mechanical properties, soft and rigid segments within a part and impact resistant structures,” says ORNL materials scientist Vidya Kishore.

The two materials used in the build were a blend containing 100% recycled CF/ABS and standard CF/ABS and ABS Syntactic foam.

Besides the ecological benefits of using recycled materials, Cincinnati Inc. says the advantages of multi-material extrusion include incorporating conductive circuit printing for smart structures, lightweight core structures, lower costs for tooling, easier removal of support material, localized reinforcement of specific areas, the capability to use different materials in different features on the component and even changing the color of the part.

3D-printed multi-material composite tool.

The key to the accomplishment of the goals outlined above was the BAAM multi-material system, developed in conjunction with ORNL. The large dual-material thermoplastic extrusion system reportedly enables the user to print with multiple different materials within a single build using just one extruder.

“The source of material fed into the extruder is switched on the fly at specific times during a print by sliding two material ports back and forth over the infeed to the extruder,” says Riestenberg. “The system also includes a material blender outside the frame of the machine that can blend specific amounts of different materials and fillers on the fly for specific custom material grades.”

Riestenberg explains that the combination of the material feed switching mechanism and the material blender gives users the ability to print with several different types of materials and material combinations within a single build, instead of two.

“The BAAM with a multi-material system upgrade is the only machine that can currently do this, and that sets us apart from our competitors,” says Riestenberg. “With the scientific research support of DOE’s Advanced Manufacturing Office and ORNL, we’ve been able to achieve this manufacturing milestone.”

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)