Composites industry stalwart Chuck Segal dies at age 91

Segal built a long, impressive career in the composites industry and developed a strong specialization in the manufacture and application of carbon fiber in aerospace and automotive parts and structures.

Share

Read Next

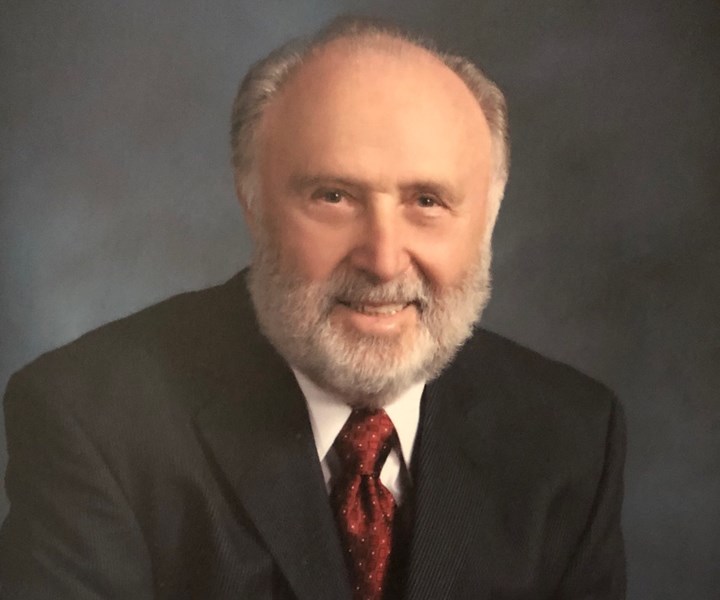

Chuck Segal.

Longtime composites veteran Dr. Charles (Chuck) Segal passed away in North Carolina on April 5 at age 91 of complications from Parkinson’s disease. Segal built a long, impressive career in the composites industry and developed a strong specialization in the manufacture and application of carbon fiber in aerospace and automotive parts and structures.

Friends and colleagues expressed their gratitude and respect for Segal’s service to the composites industry. Tom Haulik, sales director-carbon fibers, at Hexcel (Stamford, Conn., U.S.), says, “Chuck was one of the true pillars in the carbon fiber industry. He was knowledgeable on every aspect of carbon fibers and always eager to share what he knew. He left his mark on the carbon fiber industry and will be forever remembered for it.”

Scott Stephenson, director-strategic initiatives and events at CompositesWorld, and founder of the Carbon Fiber conference, says Segal was a highly respected mainstay of the industry: “Chuck was a pretty self-effacing guy, but the truth was that he knew far more about the production and production economics for the manufacture of carbon fibers and their composites than most people realized. He was a seminar instructor, speaker and active participant at the Carbon Fiber conference for more than 15 years and a mentor to me. I will miss him.”

Peter Oswald, formerly an executive of at Teijin (Tokyo, Japan) and Zoltek (Bridgeton, Mo., U.S.) and now an industry consultant, says, “Chuck was a great guy and so generous with his time and knowledge. He helped build our industry.”

Segal’s full obituary can be found here.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.