Covestro’s recycled thermoplastic resins support circular economy for electronics

Cooperation with smartphone manufacturer, Fairphone, includes use of partly and fully recycled TPU and polycarbonate resins, including glass fiber-reinforced grades.

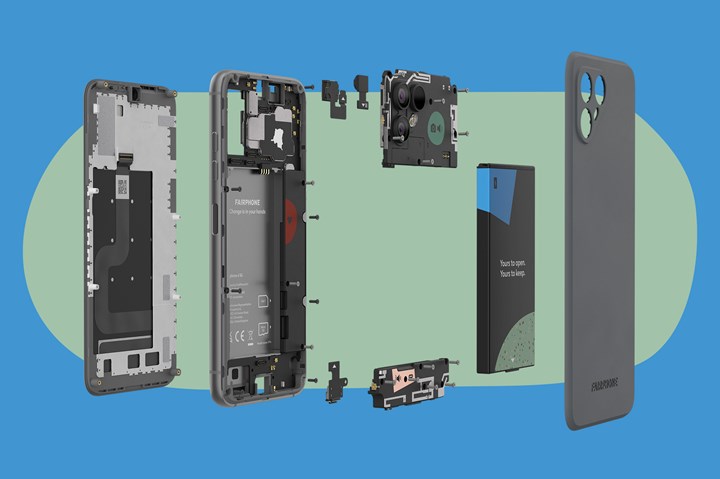

The Fairphone 4, with a glass fiber-reinforced center frame. Photo Credit: Fairphone

Covestro (Leverkusen, Germany) is collaborating with Fairphone (Amsterdam, Netherlands) on the use of circular material solutions for the Dutch social enterprise’s smartphones. Fully and partly recycled thermoplastic polyurethanes (TPU), are used in the protective case of the Fairphone 3 and its successor, the Fairphone 4, as well as glass fiber-reinforced grades for the smartphone frames. Partly recycled polycarbonate resins are additionally used in the newer device.

Products from Covestro's post-consumer recycled (PCR) polycarbonate portfolio, Makrolon, are used in the Fairphone 4’s rear device cover, middle frame and wireless charger. With a PCR content of 30-50%, Covestro says this portfolio has physical properties comparable to virgin material and offers good impact strength, balanced flow behavior, high stiffness and flame retardancy to ensure a long service life, while also reducing CO₂ emissions by 30% compared to virgin material.

Covestro has also developed a new range of recycled and partially recycled TPUs under the Desmopan brand, which are now used in the protective cover of the Fairphone 4 and are certified according to RCS (Recycled Claim Standard), an international standard for the traceability of recycled raw materials within supply chains.

This includes the product, Desmopan 3095AU RC100, which was developed after identifying several streams of post-industrial recycled plastics. The fully recycled material exhibits the typical advantages of TPU — for example, high chemical and abrasion resistance, but easier processability because it melts at lower temperatures and flows better than virgin material. The product has proven itself when used in the protective case of the Fairphone 3 and is now being used in the Fairphone 4. It is available in three color variants: gray, green and pink.

Fairphone devices are known for their modular design, which favors better repairability. Such a design requires materials with robust mechanical properties to enable repeated disassembly and repair. The glass fiber-reinforced grade of the Makrolon PCR portfolio are said to offer a good solution for the heavily stressed center frame of the Fairphone 4, and the increased stiffness and impact resistance are in line with Fairphone’s modular design approach. Thus, Covestro also supports a mono-material approach in each case for the use of polycarbonates in the housing and TPU plastics in the protective cover to facilitate recycling of the smartphones at end of life (EOL).

“With the help of our PCR portfolio, we support Fairphone in achieving its sustainability goals. This includes particularly robust material solutions that enable a modular design of Fairphone products and promote their repairability,” says Nan Hu, VP head of global industrial marketing, electronics and electrical, in the Engineering Plastics business entity at Covestro. “Such projects and collaborations are in line with our vision to become fully circular.”

“This is just a first step, and we will continue to support Covestro in developing more sustainable materials,” concludes Wayne Huang, VP product operations at Fairphone.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;maxWidth=300;quality=90)