CRP USA achieves AS9100 Rev. D certification

The certification enables CRP’s manufacture of 3D-printed aerospace products from its customer's component design data.

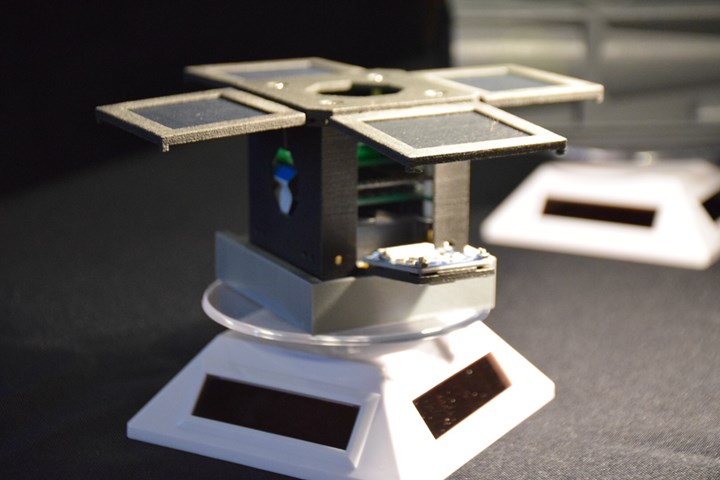

Photo Credit: Mini-Cubes

CRP USA (Mooresville, N.C., U.S.), additive manufacturing and high-performance composite materials company, announced that it has recently achieved AS9100 Rev. D certification for the manufacture of 3D-printed aerospace products from its customer's component design data. AS9100 is the international Quality Management System standard for the aviation, space and defense (AS&D) industry, created by the IAQG (the International Aerospace Quality Group; Brussels, Belgium) and is said to signify CRP USA’s ongoing commitment to meeting and exceeding increasingly stringent industry requirements for aerospace related products.

"We have taken our expertise in additive manufacturing solutions to new heights to produce parts for the most demanding sectors as aerospace and defense," says Stewart Davis, director of Operations, CRP USA. “Our team is working alongside key space industry leaders, supplying value-added high-performance 3D-printed products to meet their needs. AS9100 Rev. D certification reflects our dedication to achieving the highest standard of customer satisfaction; moreover, it is a further demonstration of the effectiveness of additive manufacturing and use of Windform as structural materials for space and aerospace applications.”

Related Content

-

Plant tour: Renegade Materials Corp., Miamisburg, Ohio, U.S.

Renegade Materials is known for high-performance prepregs for aerospace applications. Following its acquisition by Teijin in 2019, the company has expanded capacity and R&D efforts on a range of aerospace-targeted materials.

-

Northrop Grumman, U.S. Air Force introduce B-21 Raider

The sixth-generation, composites-intensive strategic bomber aircraft represents new capabilities and flexibility supported by an advanced digital ecosystem.

-

MATECH C/ZrOC composite is deployed in hypersonic aeroshells

Ultra high-temperature insulating CMC targets hypersonics, space heat shields and other demanding applications, tested up to 2760°C under extreme stagnation pressures.