Mikrosam robotic filament winding cell to aid Cidetec composites projects

Delivery of the single-spindle robotic setup with an ATP head will advance the R&D organization’s work in CUBIC, GENEX and Carbo4power initiatives targeting sustainable composites development.

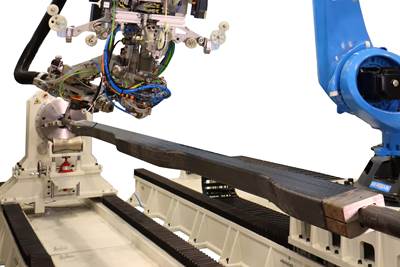

Single tape placement and robotic filament winding equipment by Mikrosam. Source (All Images) | Mikrosam

Mikrosam (Prilep, Macedonia) has deliveredy one of its robotic filament winding machine, equipped with an automated tape placement (ATP) head, to private applied research organization Cidetec (San Sebastián, Spain). The technology will support Cidetec’s projects surrounding the development of sustainable composites using its 3R (recyclable, repairable and reprocessable) epoxy resin.

Mikrosam’s single-spindle robotic setup is designed to handle wet and towpreg winding processes — for materials including carbon, glass, aramid fibers and different epoxy resin systems — as well as precise tape placement of thermoset unidirectional (UD) slit prepreg tapes, offering Cidetec optimal flexibility. There are eight interpolated axes in the winding process. Equipped with a six-axis robotic arm for accurate placement and two-axis control for spindle rotation and payout eye movement, the system can accommodate mandrels with different diameters and lengths. Mikrosam says that this enables the production of a wide range of parts, including hydrogen (H2) storage tanks — a hot topic in the market — but also another large range of products.

The single-tape placement head offers high-speed, bi-directional layup of thermoset UD prepreg tapes, emphasizing precision and adaptability for complex composite structures. Designed for both 2D and mild 3D geometries, this head is ideal for advanced aerospace and wind energy applications.

The system accommodates tapes of ½-inch width, achieving a placement tolerance of ±0.1 millimeter. A compact fiber creel minimizes material distortion and allows quick tape changes, reducing downtime. Integrated with an infrared (IR) heating unit, the system preheats the prepreg tape, ensuring optimal bonding during layup. The programmable heating power adjusts in real time to match the layup speed, ensuring consistent temperature control.

Mikrosam’s Winding Expert software further enhances the system’s capabilities with simulation and programming features, and a Quality Control System tracks and records essential production data.

Cidetec plans to use this equipment for several European epoxy development projects, starting with the CUBIC project, which focuses on the development of bio-based sustainable composites. These composites, using Mikrosam’s filament winding technology, will be a critical component in the production of H2 tanks. The goal is to offer a bio-based alternative that supports the green and digital transformation of the manufacturing industry.

According to Dr. Eva García Lecina, deputy director of Cidetec Surface Engineering, “this equipment will help us take our developments to the next level, contributing to the use of more sustainable composites in the energy, aerospace and automotive sectors.”

Cidetec will also employ this system in two other projects. The Carbo4Power project aims to manufacture sustainable wind turbine blades using the ATP machine with Cidetec’s 3R epoxy resin. This initiative seeks to enhance the performance and durability of offshore wind and tidal turbine blades while reducing energy production costs, maintenance needs and environmental impact. The project’s goal is to recycle up to 95% of blade materials thanks to the properties of Cidetec’s 3R resins, which enable debonding on demand.

The second project, GENEX, targets the aerospace sector and focuses on optimizing manufacturing and maintenance for next-generation aircraft composite structures. Cidetec has been collaborating on this project for a year, working on formulating and characterizing aeronautical-grade 3R resins and developing prepreg tapes with integrated fiber optic sensors. These materials will be used to manufacture access panels for aircraft through Mikrosam’s ATP process.

“One of Mikrosam’s key strengths is the flexibility of its machines, which can be tailored to meet our customers’ unique requirements,” says Vele Samak, vice president of Mikrosam. “The delivery of this advanced filament winding and tape placement system will empower Cidetec to achieve the highest levels of performance and efficiency in their manufacturing processes. Additionally, our collaboration on these projects positions us at the forefront of the global challenge for a cleaner, greener future.”

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreRead Next

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreMikrosam equips BTU Germany with single-tape AFP head for Type 5 pressure vessels

Delivery of upgraded placement head provides additional automated layup flexibility, quality control for the university’s latest projects advancing Type 4 and 5 hydrogen storage.

Read MoreCygnet Texkimp supplies filament winding cell to TWI Materials Integrity Centre

Versatile composites equipment will support the global R&T organization’s research and manufacturing of novel materials and parts for pressure vessels and pipes.

Read More

.jpg;maxWidth=300;quality=90)