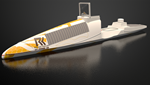

Melker of Sweden accomplishes sea kayak with 100% sustainable composite construction

Built with ampliTex flax fabrics, a solid cork core and plant-based resins, the company’s Värmdö kayak model highlights an environmentally conscious design for paddlers of all levels.

Melker of Sweden’s (Solna) approach to innovation and sustainability has been realized through the Värmdö sea kayak. Its shift toward lightweight, high-performance and plant-based construction has been achieved through the use of Bcomp Ltd. (Fribourg, Switzerland) ampliTex flax fibers, Sicomin (Chateuneuf les Martigues, France) GreenPoxy resins and GreenCoat gelcoats and a cork core. The kayak recently won Product of the Year 2025 in the Sea Kayaking category at the Paddle Sports Show in Strasbourg, France.

Melker kayaks are designed and developed in Sweden. Värmdö highlights a sandwich layup with a solid cork core (harvested from the bark of cork oak trees) and flax fiber reinforcement. The structure is vacuum infused with GreenPoxy resins, heat cured and finalized with a GreenCoat gelcoat. Melker says this approach provides a combination of high mechanical properties with a design that is environmentally respectful.

The Värmdö is aimed at a broad range of paddlers — from beginners to experienced paddlers looking for a versatile kayak that can handle everything from relaxed paddling to more adventurous activities like surfing and exploring rocky areas.

For 2025, all Melker models will feature this same construction approach, incorporating Bcomp flax reinforcement fabrics, Amorim cork and plant-based resins and gelcoats from Sicomin.

In addition to these innovations, Melker is involved in in-house R&D and rapid prototyping using large-scale additive manufacturing (LSAM) for a more efficient product development, and a new plant-based material. “This is significant for us,” the company says. “We can listen to the market's needs and quickly 3D print a full-sized prototype in one piece, which we can then intense field test in natural conditions and under different circumstances. We repeat the process until we are completely satisfied. In the final step, we manufacture molds for efficient and sustainable serial production.”

The material used for 3D printing Melker’s prototypes is recycled kayaks — shredded and re-compounded with upcycled fishing nets collected on Sweden’s west coast, along with wood fibers from Finnish pine forests. This means that not only the finished product is plant-based, but the prototypes are also created from recycled, upcycled and plant-based materials

Melker of Sweden was founded in 2015 in Hammarö by local serial entrepreneur, innovator and designer Pelle Stafshede, with the ambition to completely game-change the outdoor hardware industry. “We are honored to receive this award, and it’s a great acknowledgment of our efforts in making high-performance and more sustainable products,” says Stafeshede, CEO and creative director. “It’s a true collective effort, and we’re excited to share it with our highly valuable partner Bcomp, with whom we’ve enjoyed working together with for many years. We’re just getting started.”

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.