Dawn Aerospace UAV spaceplane certified for flight, develops smart COPVs

Targeting multiple flights/day, nitrous-based propulsion company also works with Com&Sens and ESA to develop composite-overwrapped pressure vessels with embedded sensors toward qualified 30-liter tanks by 2025.

The Mk-II Aurora, a spaceplane with a primary composite structure from Dawn Aerospace (ChristChurch, New Zealand), has been awarded a certificate by the Civil Aviation Authority (CAA, U.K.) to fly at unlimited speeds, including supersonic, up to 80,000 feet in altitude. This certification permits operations beyond visual line of sight (BVLOS) without the need for restricted airspace.

The Mk-II Aurora is a rocket-powered aircraft, designed to be the first vehicle to fly to 100-kilometers altitudes — the edge of space — twice in a single day. The company says it is rapidly reusable and low cost, making it well suited for a variety of applications in microgravity, high-speed flight research, earth observation, and other defense and civil uses.

“This unlocks the next major performance milestone for the Mk-II vehicle, namely supersonic flight,” says Stefan Powell, CEO of Dawn Aerospace. “To the best of our knowledge, this would be the first privately funded UAV to break the sound barrier. Receiving this certification is a testament to the hard work and dedication of our team, and their ability to operate such a high-performance vehicle to the standards the CAA expects of any aircraft operator.”

This certification is the result of years of close collaboration between Dawn Aerospace and local agencies, including the CAA, NZ Space Agency, Airways and local airspace users. Together, they have worked to understand how to safely integrate high-performance vehicles with existing airspace users, addressing the necessary vehicle and operational requirements. Since the first flight of the Mk-II Aurora in July 2021, Dawn has completed 50 flight tests under jet and rocket power, operating under more restrictive licenses. The Mk-II vehicle has undergone extensive upgrades and testing since its last flights in 2023, where it achieved speeds of 200 knots and altitudes of 9,000 feet. The final pre-flight test, an all-up systems test, included a 60-second firing and restart of its engine to demonstrate go-around capability.

The Mk-II Aurora is now poised to take a significant step toward its ultimate goal of flying to 100-kilometers altitude multiple times per day. Achieving this would also set records for speed, altitude and climb rate for a self-powered aircraft. “At full performance, the Mk-II will fly faster and 2.5 times higher than any prior aircraft that takes off from a runway, including the current record-holder, the SR-71 Blackbird,” Powell claims. “That is the power of bringing rocket performance to an aircraft platform.”

The upcoming flight test campaign, scheduled from July through September, will consist of up to a dozen flights. The primary objective is to expand the vehicle’s envelope to Mach 1.1 (supersonic) and 70,000 feet. A secondary objective is to demonstrate two flights in a day to showcase rapid reusability.

Dawn, Com&Sens and ESA partner on smart COPVs

Dawn Aerospace also continues to expand its satellite propulsion system offering by partnering with Com&Sens (Eke, Belgium) to work on smart composite-overwrapped pressure vessels (COPVs) with a development contract from ESA Advanced Research in Telecommunications Systems’ (ARTES) Core Competitiveness program.

The goal of the project is to develop lightweight and smart COPVs for Dawn Aerospace’s nitrous-based propulsion technology, using embedded sensors. These tanks will be capable of supporting large satellite systems and geosynchronous orbit (GEO) missions.

“COPVs are the logical next step in expanding our product offering,” says Powell. “They are essential for larger satellites doing the most challenging, high-performance missions. Using smart technology during the development allows us to bring a better product to market, faster.”

Propellants are traditionally stored in metal tanks in orbit, but size is constrained due to the weight of metals such as Inconel and titanium. COPVs offer a lightweight structure with high tensile strength and durability, making them ideal for withstanding the harsh conditions of space, including extreme temperatures and radiation.

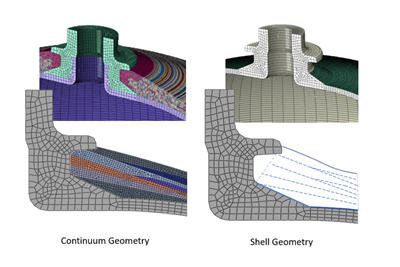

Dawn is designing and manufacturing 30-liter tanks with an aluminum alloy liner, which are then overwrapped in carbon fiber and epoxy, in precise patterns, using a filament winding machine. Com&Sens is developing solutions for semi-automated sensor embedding during the COPV winding process and is digitizing the production and testing parameters using embedded strain and temperature FBG optical fiber sensors.

Using smart sensors in the process accelerates development and gives much deeper insight into the COPV laminate and thus the quality of the vessel during production and traditional testing. Also being explored are novel ways to embed heaters into the tank liner or overwrap to control pressure in the tanks. The companies aim to have the tank qualified in Q4 2024 and available in 2025.

Related Content

Midnight production aircraft completes full transition flight

This is Archer’s second full-scale eVTOL aircraft to achieve this milestone, critical to being able to carry commercially viable passenger payloads.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreComposites end markets: Aerospace (2023)

With COVID in the past and passengers flying again, commercial aircraft production is ramping up. The aerocomposites supply chain is busy developing new M&P for an approaching next-generation aircraft program.

Read MoreLilium launches M&A process, targets eVTOL program continuation

Despite court-approved insolvency filings and beginning first investor briefings, Lilium remains fully focused on re-emerging following restructuring, setting its sights on fresh investment to support the Lilium Jet.

Read MoreRead Next

Petronas launches ProTough+ additive, signs JDA with HyPerComp Engineering

Additive targeting enhanced composite material strength is to undergo performance testing, collaborative deployment for COPVs.

Read MoreImproving analyses of composite pressure vessels

Accurate geometry modeling and equivalent material property approximations captured by WoundSim will play a role in improving COPV analyses.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)