Deutsche Aircraft begins final assembly facility construction for D328eco turboprop

In addition to the Industry 4.0 and eco-friendly facility being built at Leipzig/Halle Airport, the composite D328eco, said to be leading the turboprop resurgence, will be built with sustainability in mind.

Rendering of the new environmentally friendly facility in Leipzig/Halle Airport. Photo Credit: Deutsche Airport

On May 16, the management team of Deutsche Aircraft (Oberpfaffenhofen, Germany) and stakeholders and representatives from Leipzig/Halle Airport, the German government and the Free State of Saxony met for the ground-breaking ceremony of the final assembly line for the new 40-seat turboprop aircraft, the D328eco. The 62,000-square-meter facility will have a production capacity for 48 D328eco aircraft per year. In addition to the production hall, a flight readiness hangar will be built for aircraft delivery, along with a logistics center and an administration building with parking spaces.

An updated version of the Dornier 328 regional turboprop, the D328eco aircraft is meant to bring sustainability to the forefront, delivering “a two-meter stretch to the fuselage to accommodate up to 43 passengers and new Pratt & Whitney [East Hartford, Conn., U.S.] PW127S engines” which the company hopes to eventually run on 100% sustainable aviation fuel (SAF), according to AINonline.com. Said to be the only passenger aircraft to offer two forms of propulsion — as either a turboprop or a jet — a quarter of the D328eco’s construction uses composite materials.

In a 2021 release, GKN Aerospace (Redditch, U.K.) announced its selection for “the development of the empennage and the industrialization of this airframe main assembly which includes the rear fuselage and the vertical and horizontal tail plane fin.” The empennage will feature advanced lightweight solutions involving state-of-the-art composites technology. Another announcement made in July 2022 notes that Deutsche Aircraft appointed Aciturri (Burgos, Spain) as reference supplier for selected composite technologies. The contract, signed at last year’s Farnborough Air Show, stipulates that Aciturri will manufacture the fairings, landing gear doors and flight control movables, using composite and metallic technologies. Aciturri will also ensure the assembly of the components for integration on the final assembly line. Together, Deutsche Aircraft and Aciturri aim to deliver the first aircraft prototype in the last quarter of 2024, as well as some parts of subsequent prototypes planned for 2025.

Read, “The next 10 years in commercial aviation and composites”

AINonline.com notes that the aircraft will be built using “the latest REACH requirements for environmental sustainability covering all materials and manufacturing processes.” As part of this commitment, sustainability is also the focus of the Leipzig factory operations.

“At Deutsche Aircraft, we take great pride in the construction of our state-of-the-art and climate-friendly final assembly line,” Nico Neumann, COO, Deutsche Aircraft, says. “The assembly line will be built and operated in compliance with the best industry practices and sustainability principles.”

The facility is designed to be climate-friendly, with a CO2-neutral energy concept and extensive use of renewable energy. Moreover, production at the assembly line will be paperless throughout all processes with automated and driverless transport systems, automated parts and tool storage and 3D model-supported production with the possibility of augmented reality.

Sebastian Böhnl, director of infrastructure and digitalization, Deutsche Aircraft, outlines the energy concept for the whole production facility. “We will produce around 750 kilowatts of solar power with a photovoltaic system on the roof. From the use of heat pumps, the optional expansion with energy storage, green spaces on the roof and the wood-concrete hybrid construction, to electric charging stations for cars and bicycles, this innovative investment is well-integrated into a sustainable production ecosystem.”

Related Content

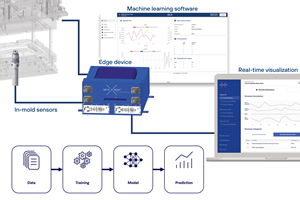

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MoreCom&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.

Read MoreDLR develops safe, flexible workspaces for robot-assisted manual draping

The EU project Drapebot works on new ways of collaborating with industrial robots for manual CFRP preforming for large aircraft structural parts.

Read MoreSiemens Gamesa, Airborne develop automatic preforming robot system for offshore wind blades

Danish-funded ALMA project furthers collaboration, adds new functionality, advanced sensor systems and digital twinning for reduced man-hours, waste and cost per blade.

Read MoreRead Next

Airbus C295 technology demonstrator makes maiden flight, proves novel design, manufacturing processes

C295 Flight Test Bed 2 (FTB2) tests OOA composite semi-morphing wing, flaps and flap tabs, as well as SatCom antenna for future turboprop aircraft.

Read MoreGKN Aerospace opens new Netherlands-based Global Technology Center

The Hoogeveen facility provides an R&D space focused on lightweight thermoplastic composites and advanced electrical cabling systems for next-gen aircraft.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)