DLR develops safe, flexible workspaces for robot-assisted manual draping

The EU project Drapebot works on new ways of collaborating with industrial robots for manual CFRP preforming for large aircraft structural parts.

Using lightweight materials in low-rate production, as is common in the aircraft industry, is still highly dependent on manual labor. For years, continuous efforts were made to automate processes for composite materials — carbon fiber-reinforced polymers (CFRPs) in particular — using complex tools and machines to imitate the existing certified processes. This, however, often leads to high investment and reduced flexibility. Another approach, focused on in the EU project DrapeBot, of which the DLR – German Aerospace Center (DLR, Augsburg, Germany) is a part of, sets the highly skilled human in the center of the process, using their experience, manual versatility and adaptivity to lead the composite draping process while being supported by a robot-based system for more demanding and/or simple process steps.

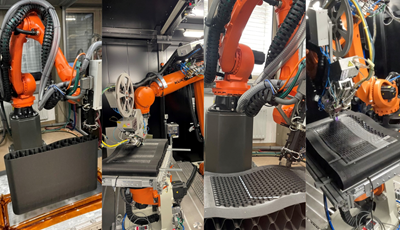

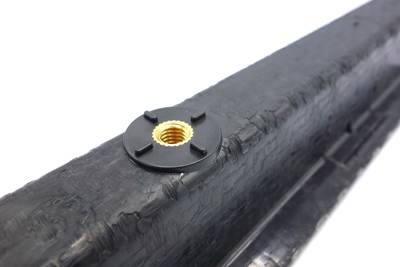

In this project, DLR focuses on the manufacture of an A350-size frame part made from dry carbon fiber within a Technology Evaluation Cell, a robot cell consisting of two KUKA (Augsburg, Germany) Quantec 210 R3100 robots arranged on a 10-meter-long linear axis. The human worker acts within the cell and in close proximity to the industrial robots. On their request (either by gesture or voice), the robots recognize, grip and transfer cut pieces from pick-up tables within the cell to the mold (multifunctional grippers are developed by Augsburg-based Abele Ingenieure GmbH). The collision-free robot trajectory by IT+Robotics (Milano, Italy) is calculated on the spot, taking the position of the worker into account while low-level control is provided by STIIMA CNR (Milano, Italy). Once the cut pieces have been placed on the mold, the robots — equipped with gripping modules and additional tools for the purpose of the process — help the worker while they are manually draping the material.

For long-cut pieces up to four meters in length, the robots hold the material above the mold, giving the worker just the right amount of material to follow its curvature. For shorter-cut pieces, the robot holds the material on various spots tightly pressed to the mold’s surface, providing seed-points for correct manual draping (see image above). The cut pieces are then fixated to the layer below. On the request of the worker, the system can measure fiber angles (sensors developed by Profactor GmbH in Steyr-Gleink, Austria) or make pictures for documentation of areas of interest specified by the worker via gesture. The process is orchestrated by a task planner developed by IT+Robotics (Padova, Italy).

Safe, flexible and intuitive workplace

The cell itself is separated by laser fences, ensuring no one other than the designated worker is operating inside it at all times. The cell layout is divided into three areas which are monitored by safety-certificated laser scanner:

- The safe area, where it is physically impossible for the robot to reach;

- The working area, where the human and robot can work in close proximity while special restrictions on the robot’s movement are imposed;

- And the forbidden area, where the worker can’t be located and thus no safe operation can be ensured. In this case the system falls into emergency stop.

The safe and working area are additionally monitored by camera-based human recognition system developed by the University of Padua (Italy), which can provide the position of the worker (for path planning) and recognize a defined set of gestures (for communication and process guidance).

Project next steps

According to the DLR, safe operation is not the only requirement regarding human-robot collaboration. Working with heavy industrial robots in close proximity also has to be addressed in the form of trustworthy relationships between human and machine. Therefore, the University of Aalborg (Denmark) is conducting studies to specifically examine the trust level of a worker based on their behavior while acting collaboratively with robots. Results could heavily influence future process, cell and robot design, in addition to providing a better understanding of human behavior for more intuitive human-robot collaboration in the future.

The technologies and procedures developed in this project are to be shown in three use cases including the one already mentioned. The other two include the part of a sports car chassis by Dallara (Parma, Italy) and a propeller for maritime propulsion by Baltico GmbH (Hohen Luckow, Germany). These projects provide a look at different use cases to better target different part geometries, materials, cell layouts and processes.

The Drapebot project, led by Profactor GmbH, runs within the EU funding program HORIZON2020 from January 2021 to December 2024 under the funding number 101006732. Initial integration and merging of the technologies on the robotic cells have taken place and the first simplified processes have been demonstrated. The next milestone is in December 2023 for the demonstration of the aerospace and automotive use cases, which will showcase a robust and continuous working process for selected cut pieces.

Related Content

How AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreSiemens Gamesa, Airborne develop automatic preforming robot system for offshore wind blades

Danish-funded ALMA project furthers collaboration, adds new functionality, advanced sensor systems and digital twinning for reduced man-hours, waste and cost per blade.

Read MoreAerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreRead Next

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Read MoreDLR project demonstrates hybrid AM process for composites

Latest DLR development in 3D printing combines additive extrusion technologies and AFP to present a new approach for manufacturing complex thermoplastic composite structures.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read More