Com&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.

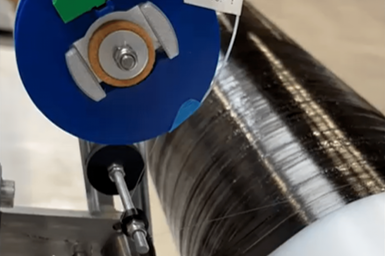

Com&Sens co-winding system illustrates an optical fiber being embedded during filament winding. Source | Com&Sens

Com&Sens (Eke, Belgium), in partnership with filament winder Sharp Composites (Herk-de-Stad, Belgium), is organizing its first hands-on training workshop on fiber optic sensing for digital manufacturing of composite pressure vessels from June 11-13, 2024 in Leuven, Belgium.

The workshop will enable participants to become proficient in sensor architecture definition, sensor embedding and data analysis throughout various composite-overwrapped pressure vessel (COPV) manufacturing processes and test phases. Com&Sens welcomes engineers and technicians involved in COPV design and manufacturing; quality assurance professionals overseeing pressure vessel production; and researchers and developers exploring advanced monitoring solutions.

Fiber optic sensing technology has emerged as a game-changer in the composites manufacturing industry, offering additional insight into the production and development of COPVs. As demand for lightweight, durable and high-performance tanks continue to rise, manufacturers are seeking innovative solutions to enhance quality control and increase speed to market.

According to Com&Sens, fiber optic sensing technology has the potential to revolutionize the way these technologies are produced, something that will be emphasized throughout the workshop. Ultimately, the interactive learning approach aims to enables participants to develop proficiency in embedding sensor fibers during winding processes, ensuring they can apply these techniques effectively in their own operations.

Key highlights of the workshop will include:

- In-depth sessions on fiber optic sensing principles and applications in COPV manufacturing.

- Hands-on training in sensor embedding techniques and data analysis.

- Case studies and real-world examples demonstrating successful implementation of fiber optic sensing solutions.

The workshop, is split across three days: Theory, practice and analysis. Day 1 (June 11) will run from 11:30 – 7 p.m. at the PetaHotel in Leuven. Day 2 (June 12) will be based at Sharp Composites, from 9 a.m. – 7 p.m. and Day 3 (June 13) is from 9 a.m. – 3:30 p.m. at the PentaHotel. Additional evening plans are offered.

There are only 15 spots available. For more information or to register, visit this link.

Related Content

-

Honda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

-

Alef Aeronautics earns FAA approval to launch flying car

FAA certifies testing of California startup Alef’s all-electric composite vehicle, which is drivable on public roads and has VTOL capabilities.

-

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.