Dieffenbacher, Arburg partner to offer combined injection/transfer molding process

The companies demonstrated their combined capabilities with a recent project to develop a modular injection/transfer molding cell to produce hybrid parts.

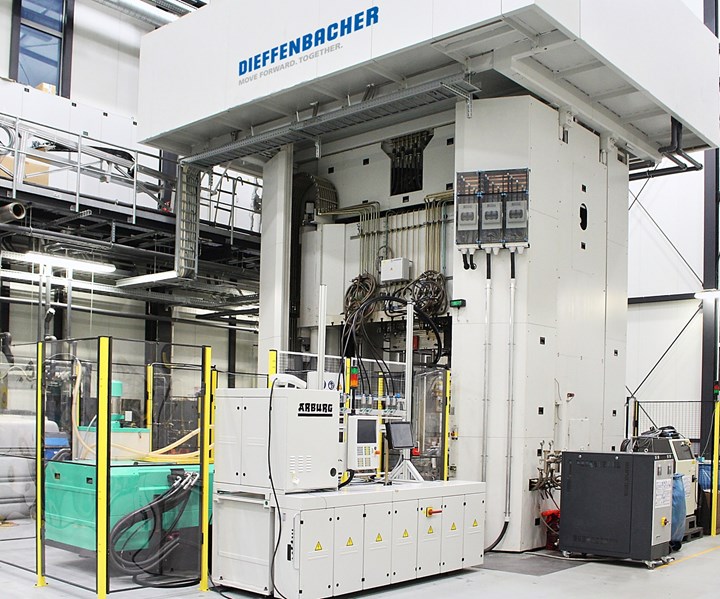

Source | Dieffenbacher and Arburg

Dieffenbacher (Eppingen, Germany) and Arburg (Lossburg, Germany) have announced a collaboration for the development of new solutions for transfer molding of hybrid components, combining their expertise in the fields of automated press molding and injection molding technology.

Arburg and Dieffenbacher recently collaborated on a research project to develop a “modular production plant for heavy-duty hybrid components,” or MoPaHyb, which was funded by the German Federal Ministry of Education and Research (BMBF).

With the participation of Fraunhofer ICT (Pfinztal, Germany) and nine other partners, the companies developed a system that combines an Arburg 4,600-kilonewton injection unit for fiber direct compounding (FDC) with a Dieffenbacher 3,600-ton vertical press. This multi-machine cell is located at Fraunhofer ICT. Arburg's FDC injection process allows fibers to be added directly to the plastic melt. In this process, fiber length, fiber content and material combination can be customized to meet specific part properties. The modular system the partners developed is said to enable the production of parts with dimensions and complexities that could not be manufactured previously.

The technology combination offered by MoPaHyb allows continuous-fiber reinforcements to be preformed and consolidated in the Dieffenbacher press, followed by injection overmolding of a chopped fiber-reinforced thermoplastic material via the Arburg machine. The result is a hybrid part that offers the strength and stiffness benefits of continuous-fiber structures, combined with potentially ribbed and other geometric reinforcements provided by injecton molding. The companies expect this material and process combination will open new areas of application in structural parts.

“The subject of lightweight construction is an important one at Arburg,” says Gerhard Böhm, managing director of sales at Arburg. “We offer various processes and solutions, including the FDC process. Combining it with transfer molding is a forward-looking concept that enables new lightweight construction applications.”

“Based on the positive results achieved in the MoPaHyb project, we will in future also be offering Dieffenbacher transfer molding presses in combination with an Arburg FDC injection unit. Together with our Fiberforge UD [unidirectional] tape laying system and the Fibercon consolidation unit, we can offer our customers a strong overall package,” says Manfred Reif, head of the composites business unit at Dieffenbacher.

Dieffenbacher is presenting this concept at K 2019 in Düsseldorf, Germany, Oct. 16-23, 2019.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Paris Air Show 2023 highlights

The Paris Air Show, one of the largest aerospace trade shows in the world, returned for the first time since 2019 and proved that the global aviation industry industry is very much alive and kicking.

-

Dawn Aerospace reusable rocket-powered aircraft flies twice in one day

Eighth and ninth flights of composites-intensive Mk-II Aurora reach an altitude of 63,000 feet, demonstrates same-day reusability capability for rocket-powered systems.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)