EconCore, Renolit honeycomb sandwich panel developments explore diverse applications

EconCore lightweight honeycomb enables Renolit Gorcell product line to overcome technical challenges and push the application spectrum for automotive and other markets like furniture and garden.

Photo Credit: EconCore, Renolit SE

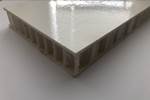

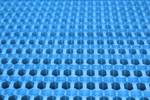

Honeycomb technology company EconCore (Leuven, Belgium) and Renolit SE (Rheinland-Pfalz, Germany) have partnered to explore the various issues of lightweighting, modular design and easily formable and rigid structures for the automotive industry and other markets via EconCore’s polypropylene (PP) honeycomb core. Through this collaboration Renolit has also seeked to improve chemical, thermal, water-resistance and rot-resistance properties.

Granted a license by EconCore for the continuous production of honeycomb panels, Renolit’s R&D team applied EconCore’s honeycomb to its Gorcell product range. The honeycomb sandwich, which combines composite skins with a hexagonal honeycomb structure, is currently being used not only for automotive applications such as truck superstructures, but also flight cases, outdoor kitchens and bakery panels. More recently, Renolit has been selling through a subsidiary to the B2C market with products for gardens, balconies and terraces, such as tissue boxes, plant and high beets and fences.

“EconCore’s honeycomb technology really stood out for us when we needed to create solutions that were lightweight which looked terrific for a variety of applications,” says Axel Kulke, sales and marketing director of composites at Renolit. “The impact on surface properties is astounding.”

Having developed the technology over a number of years to meet the desired specification of the market, EconCore’s honeycomb has enabled Renolit Gorcell to overcome several technical challenges, such as panel planarity, reduced golf ball effect and smooth, scratch-free surfaces. According to Renolit, compared to other, standard materials on the market, its Gorcell line provides additional benefits, such as special decorative surfaces, while meeting light weight and technical performance requirements.

Further, in addition to enhancing physical properties, the honeycomb also reportedly delivers commercial benefits, which can be fully exploited if deploying continuous extrusion. The Renolit Gorcell production process currently includes film unwinding, vacuum forming, core calibration, skin layer lamination, panel calibration and cutting.

Next steps, says Renolit, involve optimizing the production line to further improve the efficiency of the process and exploring new applications.

“Using the continuous manufacturing process, we have been able to supply to Europe and have projects that span the rest of the world. Having a product that is strong, yet lightweight, is exactly what we needed when creating products as diverse as storage boxes, furniture, caravan building and automotive interiors. Renolit Gorcell has that versatility,” Kulke adds.

The partnership has also progressed both companies’ green agendas. Renolit is part of the Circular Plastics Alliance, and has made a pledge under the EU’s Europeans Strategy for Plastics. This strategy aims to increase the use of recycled plastics to 10 million tonnes by 2025, a strategy that resonates strongly with EconCore’s commitment to sustainability via its honeycomb technologies.

Bianka Nagy, marketing communications manager at EconCore says “Working with Renolit has shown that our honeycomb technology delivers a range of benefits across a wide spectrum of applications. They have really taken it up, run with it and pushed it into areas we wouldn’t have dreamed of. We look forward to continuing this ground-breaking work with Renolit in industries as diverse as automotive, caravans, outdoor and garden or beach furniture manufacture.”

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.