ENLIGHTEN program launched to speed thermoplastic composites industrialization

Multi-scale modeling, testing, sensors and machine learning will advance understanding and algorithms to achieve process control and optimization for both aerospace and automotive supply chains.

Photo Credit for all images: Dr. Remko Akkerman, University of Twente and TPRC.

The lighter a vehicle is, the less fuel it consumes and the less CO2 is emitted. Lightweight materials that are strong enough to ensure passenger safety are also popular among manufacturers of cars and aircraft. Thermoplastic composites — fiber-reinforced plastics that soften when heated — are light, strong, easy to work with and easy to recycle. Certain components in aircraft fuselages and wings are already being made from this relatively new material. However, they are not yet in wider use.

The aim of ENLIGHTEN — Enabling Integrated Lightweight Structures In High Volumes — is to find a way to produce reliable entire structures using this material in a predictable, reproducible and cost-effective way. This €6 million, five-year project is being launched by the University of Twente (UT, Twente, The Netherlands) and Dr. Remko Akkerman, scientist at UT and the ThermoPlastic composites Research Center (TPRC, Twente, The Netherlands) as part of the Netherlands-based Perspective program, which challenges scientists to establish innovative new lines of research that can have a genuine economic and societal impact. Established by the Dutch Research Council (NWO), and the Ministry of Economic Affairs and Climate, six Perspective consortia are being set up in the Netherlands, with 138 companies and organizations contributing €10 million of their own funding to match the €22 million available from the Dutch government.

Developing multi-scale details

CW spoke with Akkerman to get a better understanding of what ENLIGHTEN really entails. “CompositesWorld readers are very familiar with the work done at TPRC, where we focus on fast thermoplastic processing, including welding, overmolding and also recycling,” says Akkerman. “We have published many results studying materials, process and performance. But how does the process affect the fiber-matrix distribution and porosity in the composite? How does that, in turn, affect the mechanical performance of the part? How do these processes affect crack initiation and growth in service? These aspects need to be understood in order to mature thermoplastic composites for broader industrial use.”

This is why ENLIGHTEN is such a large program, involving specialists in polymers, composite micromechanic, and multiscale digital modeling as well as digital data science. “Our goal is to develop knowledge that we can then use to optimize these thermoplastic composite processes for optimized performance,” says Akkerman. “We will also integrate process monitoring — because the material quality relies on your ability to control the process — and machine learning to speed up this optimization.”

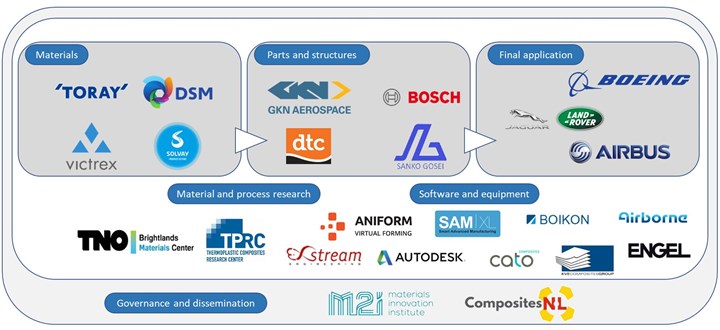

The ENLIGHTEN consortium includes 22 partners and spans both automotive and aerospace supply chains.

ENLIGHTEN includes all three technical universities in the Netherlands (University of Twente, Delft University of Technology and Eindhoven University of Technology) as well as companies throughout the automotive and aerospace supply chains, including OEMs, Tier suppliers and SMEs. Organizations outside of the Netherlands are also involved, including the University of Warwick’s WMG Centre for High Value Manufacturing as part of the U.K.’s CATAPULT program and Jaguar Land Rover, a subsidiary of global automotive manufacturer Tata Motors (Mumbai, India).

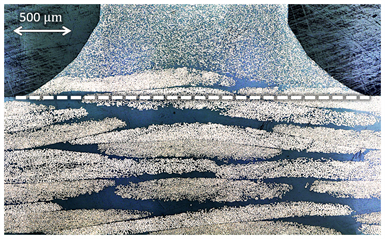

This micrograph shows some fiber migration above the weldline between a continuous fiber-reinforced blank and the short fiber-reinforced injection overmolding. How this affects the strength and performance of the part is one question among many to be answered by ENLIGHTEN.

“The processes we will investigate include induction and ultrasonic welding as well as overmolding, which also has a weld interface, each involving the same physical phenomena but at different rates,” Akkerman notes. “So, all of the same phenomena regarding fiber movement, stress and crack initiation apply here as well.” But haven’t welded thermoplastic composite structures been flying on commercial aircraft for over 30 years? “Yes, but none of those structures use induction or ultrasonic welding with unidirectional tapes,” he points out, “which is much more difficult to understand and control, but also more economical to produce if we can fully predict the processes.”

Multi-scale modeling and physical testing will play a key role in the ENLIGHTEN project. “It is impossible to understand a composite without looking at the manufacturing process used to create it,” says Akkerman. “Through digital modeling, we can formulate hypotheses and then perform experiments side-by-side to validate our results and refine our understanding. For example, this includes looking at the formation of crystalline structures at the micro level, how fibers move during the welding process at the meso level and how these phenomena interact to affect development of stress, microcracks and the ultimate loads of the structure at the macro level. This very in-depth yet combined level of investigation I have not seen yet in our industry.”

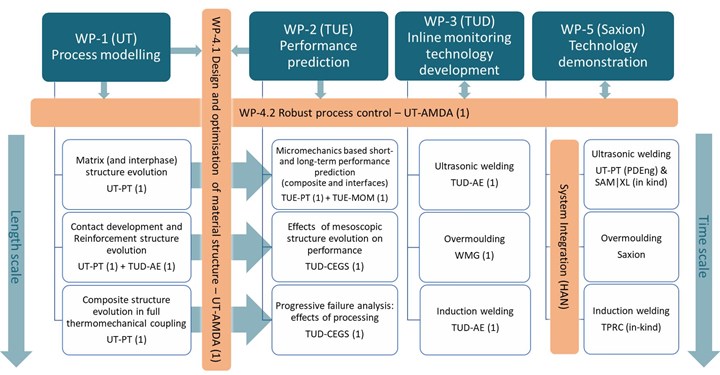

But where does machine learning come into play? “Each of the analysis elements in work packages 1 and 2 takes hours to run,” says Akkerman, “and must be repeated for each specific material, part and process. If you want to achieve optimization across all of these scales and models, it will take thousands of hours. As we do this, however, we will be accumulating data on how all of these phenomena relate to each other. We can then train neural networks to recognize connections in this data, fully in line with the underlying physics.”

Looking at the scope of work shown below, he explains, “there will be connections from left to right and top to bottom. Based on all of these analyses, our aim is to develop algorithms which can be used in a more general, flexible way without having to start from scratch each time. In other words, these algorithms can be applied to your given part, helping you to optimize your process parameters and material choices. Think of the machine learning as a type of curve fitting with many, many variables.” He concedes this is not a perfect analogy, but the outcome is effectively similar, in that the curve — which in this case is more of a multidimensional hyper-surface — will show the correlations and causalities that point the way forward.

Materials, dissemination and ultimate goal

Finalizing materials to be studied is one of the ENLIGHTEN project’s first tasks. “Most likely polyamide 6 (PA6, nylon) will be studied for automotive and low-melt polyaryletherketone (LM PAEK) for aerospace,” says Akkerman. “We will evaluate other materials and look at any and all data available.” This may include, for example, what has been generated by other programs, such as MECATESTERS in Clean Sky 2, which has done a significant amount of testing with carbon fiber-reinforced LM PAEK UD tape. Meanwhile, the Clean Sky 2 STUNNING program will be generating a large amount of data with respect to ultrasonic welding as it assembles the lower half of the Multifunctional Fuselage Demonstrator (MFFD). Akkerman points out the COMPeTE projects carried out at TPRC, which have studied overmolding for many different material combinations.

Regarding dissemination of the project’s results, the ENLIGHTEN consortium will have general meetings yearly and the subgroups in each work package will meet as necessary to achieve their established milestones. Individual presentations will be made at national and international conferences during the course of the project and a devoted session or full international conference in the final year of the project will be organized to share the overall results.

The ultimate goal, says Akkerman, is to achieve for thermoplastic composites what the metals industry has with its material design approach for monocrystalline metals in aeroengines, for example. “Their goal was to attain a performance that is necessary for the future of aircraft. We see the same mandate for a larger span of mobility. We are trying to design welding and overmolding processes to optimize the performance of lightweight thermoplastic composites for aerospace and automotive structures, but we still have so much variability. The result is excessive safety factors and less efficiency than the technologies actually offer. Yes, we have thermoplastic composite parts flying, but it took 30 years to get this far. Europe has set a goal to be carbon neutral by 2050 — that is less than 30 years. If we proceed on our same path, which still involves a lot of trial and error, we won’t meet the goals necessary for fighting climate change. We see a different, more efficient path via ENLIGHTEN and now is time to act.”

Related Content

Aerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

Read MoreIMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

Read MoreAitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)