FET awarded £50,000 AMPI grant for spinneret research

With the help of four universities, computational fluid dynamics studies will be conducted to develop more efficient version of FET’s synthetic polymer processing equipment.

Fibre Extrusion Technology Ltd. (FET, Leeds, U.K.) has been awarded £50,000 of grant funding to collaborate with the University of Manchester (U.K.) on complex spin pack and spinneret designs. The grant is awarded by a consortium led by The Advanced Machinery and Productivity Institute (AMPI) and The National Physical Laboratory (NPL). AMPI’s Innovation for Machinery (I4M) programme supports businesses in West Yorkshire and Greater Manchester as part of an overall initiative to drive innovation for the U.K.’s advanced machinery manufacturers to meet the challenges of developing new technology and entering emerging markets.

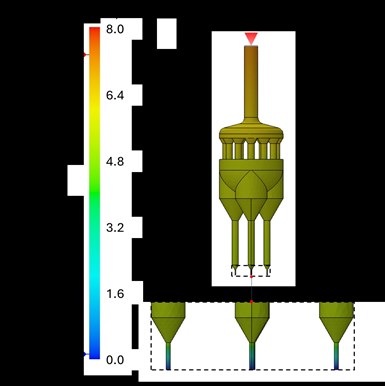

In this project, FET will be working with the University of Manchester to conduct computational fluid dynamics (CFD) studies on a number of complex spin pack and spinneret — device used to extrude a polymer solution or polymer melt to form fibers — designs. The aim of this work is to identify areas of improvement for FET’s spin packs and spinnerets and to use computer-aided designs to develop significantly more efficient versions. The goal is that the research will improve the throughput of FET extrusion systems, thus reducing the amount of polymer lost through inefficient flow paths. This development, in turn, will reduce the environmental impact of synthetic polymer processing.

FET designs, develops and manufactures extrusion equipment for a range of high-value textile material applications worldwide. Established in 1998, FET’s major strength has always been to collaborate with customers in testing, evaluating and developing high-value materials with diverse, functional properties. Efficiency and sustainability are key, so enhanced development of spinneret technology will contribute significantly to these objectives.

This funding will provide FET with access to the expertise of four universities and the NPL to develop the next generation of machinery.

For related content, read “Rheon Labs successfully completes reactive fiber collaboration trials with FET.”

.jpg;maxWidth=300;quality=90)