Firefly Aerospace to automate composite rocket production with Ingersoll AFP machine

The company plans to transition manufacture of its Alpha and Beta all-composite launch vehicles to automated fiber placement starting in 2021.

Photo Credit: Firefly Aerospace

On Oct. 29, launch vehicle and spacecraft manufacturer Firefly Aerospace (Briggs, Texas, U.S.) announced that, beginning in 2021, it will increase its large parts manufacturing operations by transitioning to automated fiber placement (AFP) using Mongoose Hybrid systems acquired from Ingersoll Machine Tools (Rockford, Ill., U.S.). Once fully operational, Firefly’s AFP capabilities will enable it to produce all of the carbon fiber components of its all-composite Alpha rocket airframe (learn more about Alpha’s design here) in as little as 14 days, the company says.

Firefly will install the first of two planned AFP systems in May 2021 at its manufacturing and test facility in Briggs, Texas, where Alpha will be requalified using AFP manufacturing processes. The second automated assembly line will be located at Firefly’s new Florida Space Coast factory and launch site at Cape Canaveral beginning in 2022. When operational, the Florida factory is said to be capable of producing an estimated 24 Alpha rockets per year, at which point the Briggs plant will switch to automated developmental builds of a larger launch vehicle, called Beta.

“From the outset, Firefly chose to utilize 21st century materials and manufacturing processes in our spacecraft and rocket designs. Metallics were the most prevalent aerospace material of the last century; composites, which are stronger and lighter than metallics, are the choice for modern aircraft. Firefly’s Alpha is the world's largest all-carbon-fiber liquid fueled rocket,” says Dr. Tom Markusic, CEO of Firefly. “High-speed, robotic, large-scale AFP machines, like those produced by Ingersoll Machine Tools, are now widely utilized in the aircraft industry. These machines essentially allow you to 3D print composite structures of very large dimensions (e.g., commercial aircraft), something that is significantly more challenging with metallic 3D printing. Given that we can simply purchase machines which have been developed and proven by the aircraft industry and immediately achieve major cost, weight and production time savings, it’s obvious to us that AFP is the most efficient and cost-effective approach to future rocket production. Firefly intends to pass those savings on to our customers.”

“As Firefly approaches our first Alpha launch, our focus is transitioning to scaling our operational capabilities to meet the fast-growing commercial, government and scientific mission demand for space access with the lightest, strongest, fastest built precision-made rocket in the industry.”

Firefly says its Mongoose Hybrid will be the first equipped with Ingersoll’s new Hawk fiber delivery module, designed and tested for high productivity and high-reliability layup of mild curvature surfaces. Mongoose Hybrid also features Ingersoll’s automatic exchange of multiple composite manufacturing modules operating in adjacent workzones, allowing automated layup on multiple tools without human intervention.

Firefly also says its new automated rocket factories will produce a broad range of benefits, including a 30-50% reduction in composite materials waste, increased repeatability, reduced touch labor and build times, and a tailored and optimized structure that further reduces weight and overall costs.

“Ingersoll is thrilled to bring our vast experience in automated composite manufacturing and robotics across the aerospace industry into the world of space rocketry and exploration with Firefly,” says Chip Storie, CEO of Ingersoll Machine Tools. “Ingersoll has played an important role in enabling breakthrough airframe production for major aircraft designs around the world, including the 787 and A350, and we look forward to supporting Firefly and its innovative approach to the efficient and cost-effective production and further development of its Alpha, Beta and future spacecraft.”

“As Firefly approaches its first Alpha launch, our focus is transitioning to scaling our operational capabilities to meet the fast-growing commercial, government and scientific mission demand for space access with the lightest, strongest, fastest built precision-made rocket in the industry,” says Markusic. “The integration of Ingersoll’s factory automation technology into our production lines in Texas and Florida represents a major investment in our future as a company and in the future of the cis-lunar space economy.”

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

Firefly Aerospace announces new customer agreements, completed acceptance tests

One step closer to launch, the Alpha launch vehicle passed Stage One acceptance testing. Spire Global and Geometric Space signed on as Alpha customers.

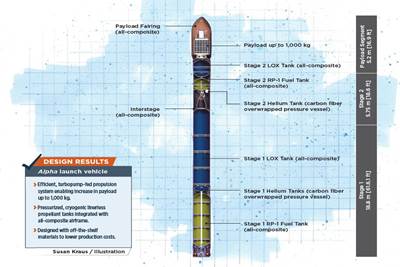

Read MoreThe Alpha launch vehicle: Designing performance in, cost out

Firefly Aerospace’s Alpha 2.0 launch vehicle, designed to deliver satellites into low Earth orbit, gets a composites makeover in pursuit of larger payload capacity and more cost-effective performance.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)