Fraunhofer IPT automates production of thermoplastic CFRP engine fan blades

Successful first demonstrations on 16-mm-thick CF/PA12 to be followed by CF/PEEK tapes and embedded sensors for structural health monitoring (SHM).

Share

Read Next

Photo Credit: Fraunhofer IPT

Materials for aircraft must be highly resilient and at the same time as light as possible. Offering both, carbon fiber-reinforced plastics (CFRP) have been used more and more frequently in aeroengine fan blades. (See “Rolls-Royce starts manufacture of world’s largest fan blades”). However, production of these components is very time-consuming and expensive because they have to cure for several hours in the autoclave. A research team from the Fraunhofer Institute for Production Technology (IPT, Aachen, Germany) is seeking to automate the production of CFRP fan blades even further.

The production of many CFRP components is already partially automated. Pre-impregnated semi-finished prepregs — typically made from fiber-reinforced epoxy resin — are applied and oriented in thin layers to create a tailored layup. This is then cured under pressure and heat in an energy-, cost- and time-intensive autoclave process. Fraunhofer IPT has been researching the possibilities of further automating the manufacture of CFRP blades to make them even more cost-effective.

However, these researchers are not relying on epoxy resin-based materials, but instead on carbon fiber-reinforced thermoplastics. These materials have already been used in flying structures for decades, have good lightweight construction properties combined with excellent impact behavior and can be processed quickly and flexibly in an automated manner. Being thermoplastic, they do not require chemical cross-linking to harden, but only heating to melt and pressure to consolidate during controlled cooling. They may also be reheated and reshaped.

Thermoplastic composites are therefore much more suitable for efficient manufacturing processes, explains Dr.-Ing. Henning Janssen, head of the fiber composite and laser system technology department at Fraunhofer IPT. In several test series, his team has now succeeded for the first time in combining two such processes for fan blade production: fully automated tape laying and forming.

Flexible process chain: automated tape laying and thermoforming

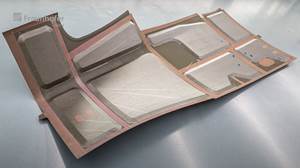

With a fully automated tape laying system, a proprietary development of the Fraunhofer IPT that is commercialized under license, unidirectional (UD) reinforced thermoplastic tapes are layered on top of one another according to the direction of load required in the structure. In this way, a multi-layer, highly resilient and flexible panel, a so-called organic sheet, is created. The researchers monitor and document every step of the fully automated process using various sensors. In this way, they can look into the “black box” of production during the process and create a so-called “digital shadow” for each organic sheet. This virtual image of the real organic sheet makes it possible to identify quality deviations at an early stage and to take appropriate countermeasures.

The finished organic sheet is heated in the next production step and shaped to near net shape in a thermoforming process. In the previous series of tests, the process was initially tested on 16-millimeter-thick, fabric-reinforced organic sheets made of PA12 and carbon fibers and is soon to be transferred to organic sheets made of PEEK and carbon fiber tapes.

Test series for milling FRP components

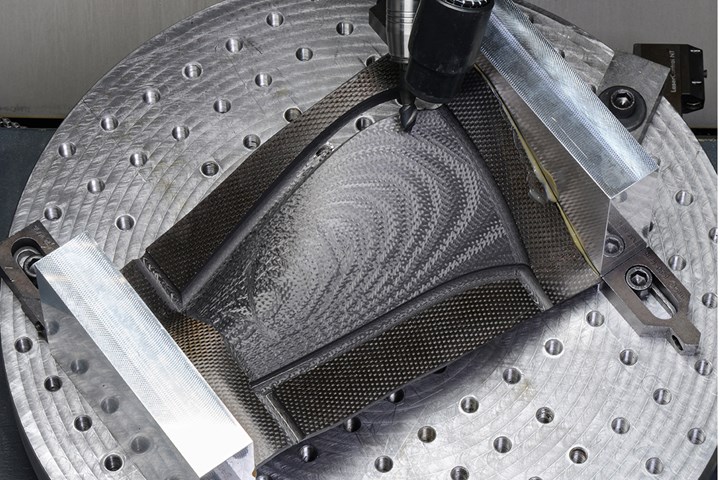

After thermoforming, the edges of the formed organic sheet are trimmed and milled into the final shape. Milling FRP is very challenging due to the heterogeneous material structure. Also, carbon fibers have a highly abrasive effect on the cutting edge of the milling tool and thus lead to heavy tool wear and fluctuating processing quality.

One possibility to extend the tool life is the use of milling tools that are coated with polycrystalline diamond (PCD). During their attempts to machine CFRP blades on a smaller scale, the researchers found that the service life of PCD-coated milling tools is significantly longer than that of uncoated tools. In addition, an individually tailored design of the milling strategy had a positive influence on the machining quality.

Implementation in various industrial application contexts

The first results with the thermoplastic CFRP materials are promising: “We were able to show that the linked manufacturing processes — manufacture and finishing of blades — work,” says Daniel Heinen, head of the Turbomachinery Business Unit at Fraunhofer IPT. “We were able to achieve very good surface qualities both in the radial blade direction and between the leading and trailing edges of the blades. Now, we have to examine and optimize the individual processes more closely.”

Research projects are planned for the next few months in which the new processes will be further optimized and examined in various industrial application contexts. The Aachen scientists are particularly interested in the use of high-performance thermoplastic PEEK as a matrix and the lamination of sensor technology inside the organic sheet. The latter would make it possible not only to monitor the manufacturing processes, but also the component status during later use in the engine. The application of the process chain to other components is also sought, for example to stators and nacelle components as well as components outside the aviation industry. Fraunhofer IPT welcomes interested companies who want to take part in the projects.

Related Content

Optimizing AFP for complex-cored CFRP fuselage

Automated process cuts emissions, waste and cost for lightweight RACER helicopter side shells.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

Read MoreRocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

Read MoreRead Next

Rolls-Royce starts manufacture of world's largest fan blades, made with composites, for UltraFan demonstrator

CFRP blades and fan case cut weight for twin-engine aircraft by 700 kilograms

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)