Fujitsu, Teijin start joint trials to promote value of recycled carbon fiber

Three-month trials with German bicycle manufacturers will lead to new platform implementation to promote use of recycled materials, enable emissions tracing/management.

Photo Credit: Teijin Ltd.

On Jan. 19, Fujitsu Ltd. (Tokyo, Japan) and Teijin Ltd. (Tokyo) announced the launch of a joint project running from January to March 2023 to enhance the environmental value of recycled resources in the production of bicycle frames. Joint trials will include V Frames GmbH (Schmiedefeld), a German manufacturer and distributor of carbon fiber-reinforced plastic (CFRP) bicycle frames, and bicycle manufacturer E Bike Advanced Technologies GmbH (Frankfurt, Germany).

As part the trials, Teijin and Fujitsu will leverage a blockchain-based commercial platform launched in July 2022 to promote the sustainable use of recycled fiber-reinforced plastic (FRP) materials, as well as trace and manage greenhouse gas (GHG) emissions within the bicycle industry.

By implementing a business model that maximizes the environmental value from recycled materials, Teijin and Fujitsu aim to contribute to the further development of the carbon fiber recycling market and the realization of a circular economy. Following the successful conclusion of the joint trials, Teijin and Fujitsu will promote the implementation of the new platform, with the aim of commercialization in fiscal 2023. The two parties will also further promote discussions and field trials with partner companies and organizations that support this initiative and will work to contribute to the realization of a circular economy by supporting the growth of the recycling market in various industries.

Future visions and goals include:

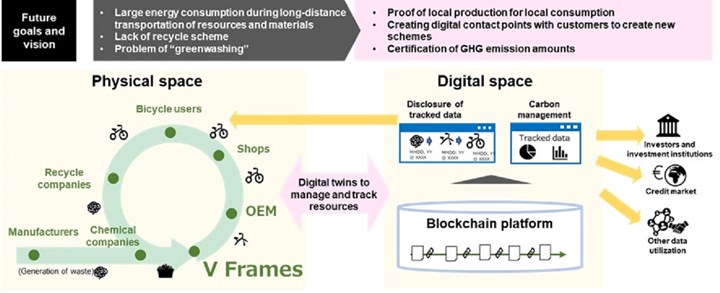

- The creation of “digital twins” to manage resources: Information about resources (their location, condition, environmental impact, etc.) used/generated in the business operations from the recycling to sales process of bicycle frames will be uploaded and provided on the platform to create digital replications (digital twins) of physical resources and manage information on their condition. Using blockchain technology, the platform will also offer past data on the condition of resources.

- Disclosure and utilization of data: Data from the platform can be used to share information on resources (origin of resources, etc.) with bicycle users, or be used by various stakeholders in their carbon management; data on the platform can further be used as proof for the successful realization of a resource cycle and applied for future ESG investment evaluations or as credits.

Throughout this project Teijin will support the environmental assessment across the different processes and engagement of stakeholders; Fujitsu will implement the blockchain platform based on the Fujitsu Track and Trust digital ledger technology and development of tool for visualization and provision of tracked data; and V Frames and Advanced Bikes will upload environmental impact information for different operational processes within the company to the platform, as well as review the data collection and visualization process.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

Teijin partners with European carbon management firms for accelerated GHG emissions reduction

Combined know-how and expertise will be used to calculate life cycle analysis (LCA) and GHG emissions for environmental impact reduction in Teijin’s FRPs and other product life cycles.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)