Hexagon Purus receives orders for H2 refueling station, H2 distribution systems

Demand for Type IV cylinders remains strong as zero-emission mobility grows worldwide.

Photo Credit: Hexagon Purus

Hexagon Purus (Oslo, Norway) has received an order from a large European OEM to deliver a mobile 700-bar hydrogen (H2) refueling station and secured a five-year framework agreement with a leading global energy company to deliver H2 distribution systems comprising its Type IV tanks using carbon fiber-reinforced polymer (CFRP) composites.

Per its order, the European OEM intends to integrate the mobile refueling station to demonstrate and verify H2 energy supply to commercial vehicles. The order is valued at around €3 million and delivery is scheduled for Q4 2024.

“Development of the next generation 700-bar mobile refueler will help to drive increased adoption of hydrogen within commercial vehicles and equipment,” says Matthias Kötter, managing director of Hexagon Purus systems’ subsidiary Wystrach, which is undergoing a facilities expansion. “Our next-generation mobile H2 refueler is easy to install and relocate, coupled with a robust concept that ensures high availability during operation.”

Hexagon Purus broke ground on the Wystrach expansion in Weeze, Germany, in April 2023. A 5,000-square-meter production hall is scheduled to be completed in October 2023. This will increase the current production area from ≈11,000 to 16,000 square meters, significantly boosting the company’s production capacity. A training center and office area will follow with eventual plans to construct a public H2 refueling station.

Photo Credit: Hexagon Purus

In February 2023, Hexagon Purus also received an order for both mobile hydrogen refueling stations and stationary storage from Deutsche Bahn (Berlin, Germany), a provider of mobility and logistics services worldwide and said to be one of the largest railway operators in Europe. Hexagon Purus’ mobile hydrogen refueling stations and stationary storage, including its Type IV hydrogen cylinders, will be used for rail and other mobile applications in Germany. The order is valued at roughly €2.5 million (approximately NOK 25 million) with delivery scheduled from Q2 2023 to Q4 2023.

Hexagon Purus has also signed a five-year supply agreement with a global energy company for H2 distribution systems using its Type IV CFRP cylinders to supply H2 for a network of refueling stations in Europe. The agreement represents potential sales of ≈€27 million.

“The demand for our distribution system technology continues to remain strong on the back of increased use of hydrogen as feedstock in industry processes but also increasingly for zero-emission mobility,” says Michael Kleschinski, executive vice president of Hexagon Purus. “Our hydrogen distribution systems based on Type IV high-pressure cylinders offers the optimal combination of weight and payload resulting in lower total cost of ownership compared to other available technologies for transportation of hydrogen.”

The mobility sector is accountable for approximately 20% of annual carbon emissions globally, and H2 has a significant role to play in reducing these emissions, particularly in “hard-to-abate” sectors. Making green H2 available for use in among other the mobility sector is critical to reduce carbon emissions. Hydrogen is a key contributor to the energy transition and continues to build momentum globally:

- More than 30 countries have released H2 roadmaps

- $320 billion in direct investments into H2 projects have been announced through 2030

- More than 1,000 H2 projects have been announced globally to date

- Green hydrogen is projected to supply up to 25% of the world's energy needs by 2050.

For more information on Hexagon Purus’ growth, see “Hexagon Purus Westminster: Experience, growth, new developments in hydrogen storage” and “Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks.”

Related Content

Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreAchieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.

Read MoreRead Next

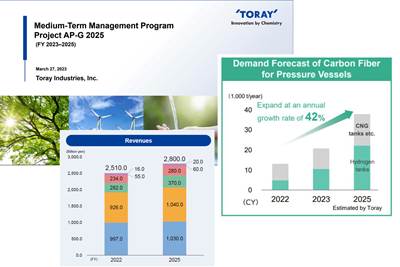

Toray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

Read MoreToray to increase carbon fiber tow capacity by more than 20%

Capital investments to Spartanburg, S.C., and Gumi, Korea facilities, in response to market demand, will increase annual capability to 35,000 metrics tons beginning in 2025.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)